Spiral hole forming drilling tool and piling construction method

A helical and hole-forming technology, which is applied in the direction of drill pipe, drill pipe, sheet pile wall, etc., can solve the problems of weak horizontal shear resistance, affecting pile bearing capacity, and strong compaction of soil, and achieves good compaction effect , Eliminate adverse effects, strong effect of squeezing soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

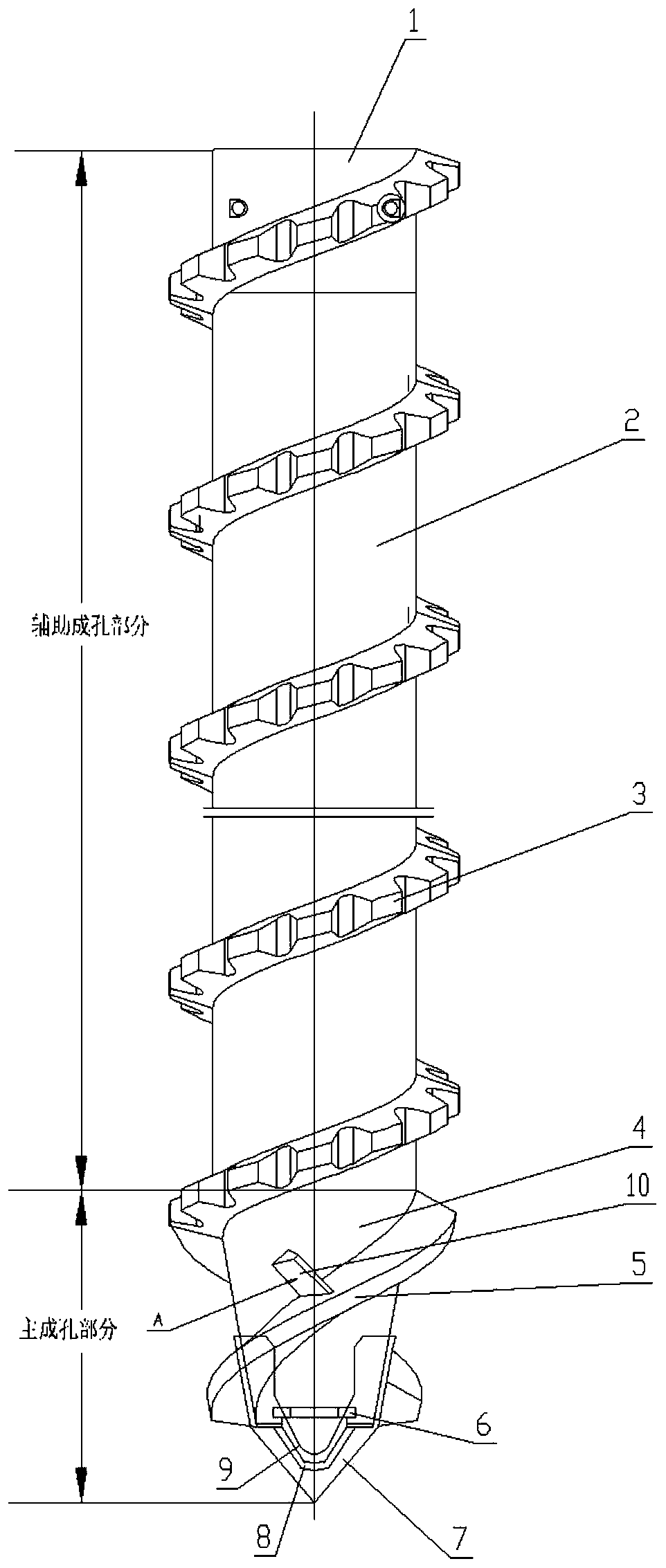

[0043] Such as Figure 1-Figure 4 , This embodiment provides a helical hole-forming drilling tool in which the core pipe of the main hole-forming part is a truncated cone and a soil retaining block is provided.

[0044] (1) A helical hole-forming drilling tool is composed of an auxiliary hole-forming part and a main hole-forming part.

[0045] The auxiliary hole-forming part is composed of several joints 1, several outer pipes 2 and spiral extruding blades I3. After several outer pipes 2 are connected together through the joint 1, the spiral extruding blade I3 is wound on the joint 1 and the outer pipe 2, and the shape formed by the outer edge of the spiral extruding blade I3 is cylindrical. The joint 1 installed at the upper end of the topmost outer pipe 2 is used to connect the spiral hole drilling tool with the power head of the pile driver. The lower end of the outer tube 2 at the bottom is fixed with the core tube 4 of the main hole-forming part. The joint 1 can be a f...

Embodiment 2

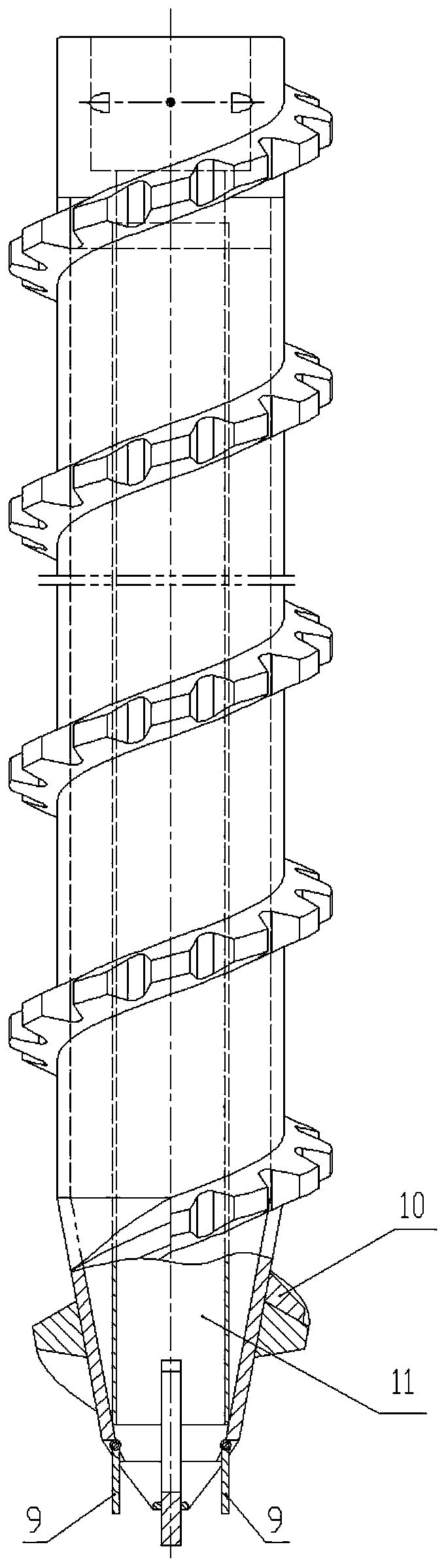

[0063] Such as Figure 5-Figure 6 , This embodiment provides a spiral hole-forming drilling tool in which the core pipe of the main hole-forming part is cylindrical and has soil retaining and squeezing blocks. The helical hole-forming drilling tool provided in this embodiment is composed of an auxiliary hole-forming part and a main hole-forming part.

[0064] The auxiliary hole-forming part is composed of several joints 1, several outer pipes 2 and spiral extruding blades I3.

[0065] The main hole forming part is composed of the core pipe 4, the spiral extruding soil blade II 5 and the drill door device.

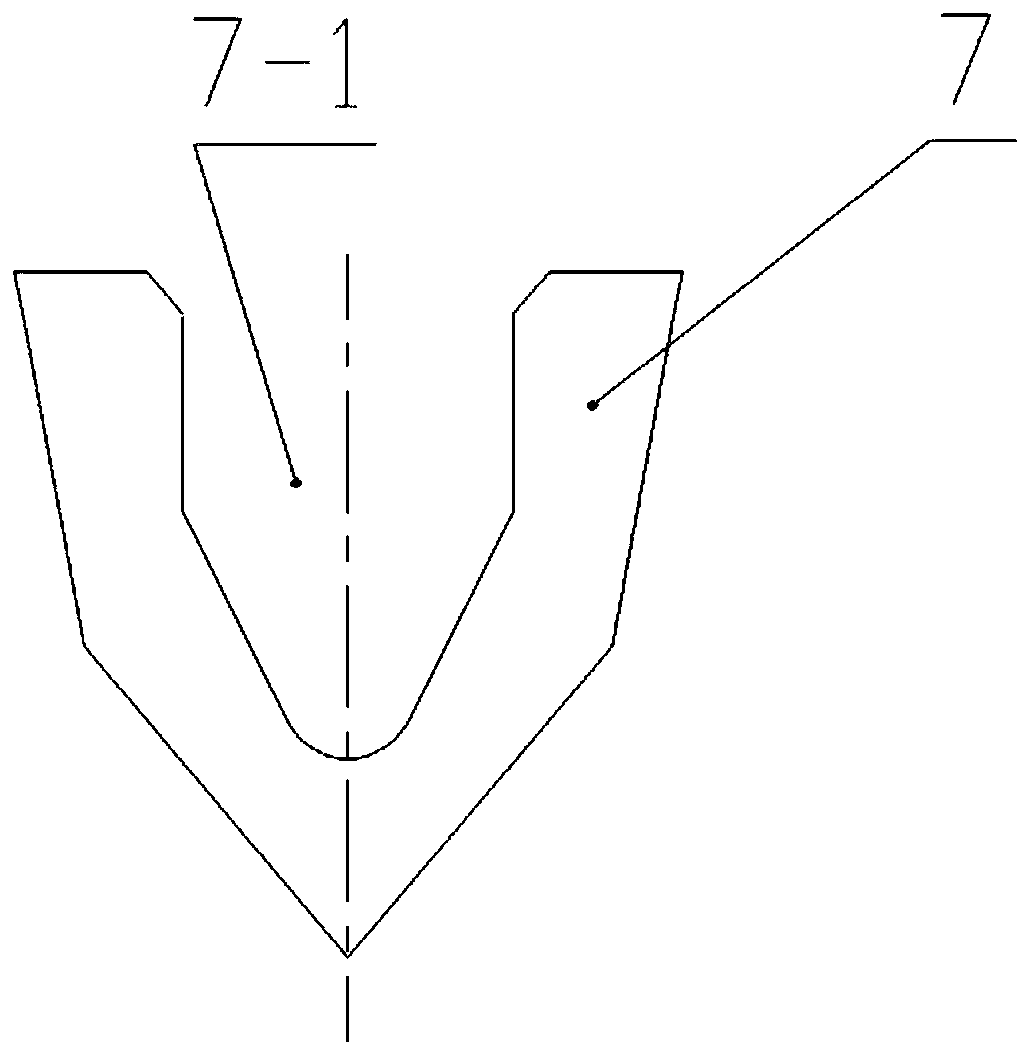

[0066] The drill door device includes a hinge group 6, a drill tip 7, a U-shaped coaming plate 8 and a drill door 9.

[0067] Several soil retaining blocks 10 are provided.

[0068] The structures of the auxiliary hole-forming part, the main hole-forming part and the soil retaining and squeezing block 10 are the same as those in Embodiment 1, except that the core pipe 4 ...

Embodiment 3

[0071] Such as Figure 7-Figure 8 , This embodiment provides a spiral hole-forming drilling tool in which the core pipe of the main hole-forming part is a truncated cone without soil retaining and squeezing blocks.

[0072] (1) A helical hole-forming drilling tool is composed of an auxiliary hole-forming part and a main hole-forming part.

[0073] The auxiliary hole-forming part is composed of several joints 1, several outer pipes 2 and spiral extruding blades I3. After several outer pipes 2 are connected together through the joint 1, the spiral extruding blade I3 is wound on the joint 1 and the outer pipe 2, and the shape formed by the outer edge of the spiral extruding blade I3 is cylindrical. The joint 1 installed at the upper end of the topmost outer pipe 2 is used to connect the spiral hole drilling tool with the power head of the pile driver. The lower end of the outer tube 2 at the bottom is fixed with the core tube 4 of the main hole-forming part. The joint 1 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com