Early-strength cement-based grouting material as well as preparation method and application thereof

An early-strength cement, cement-based technology, applied in infrastructure engineering, construction, etc., can solve the problems of reducing the early strength of cement and soil, low early strength of cement and soil, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

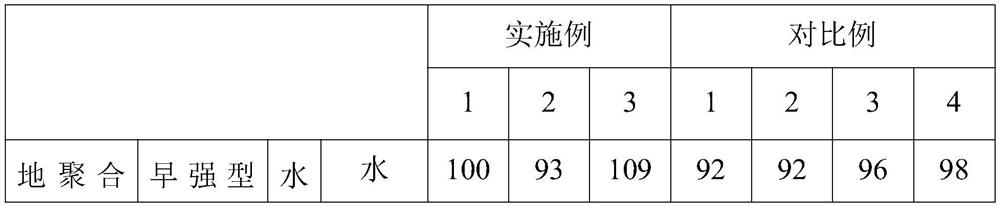

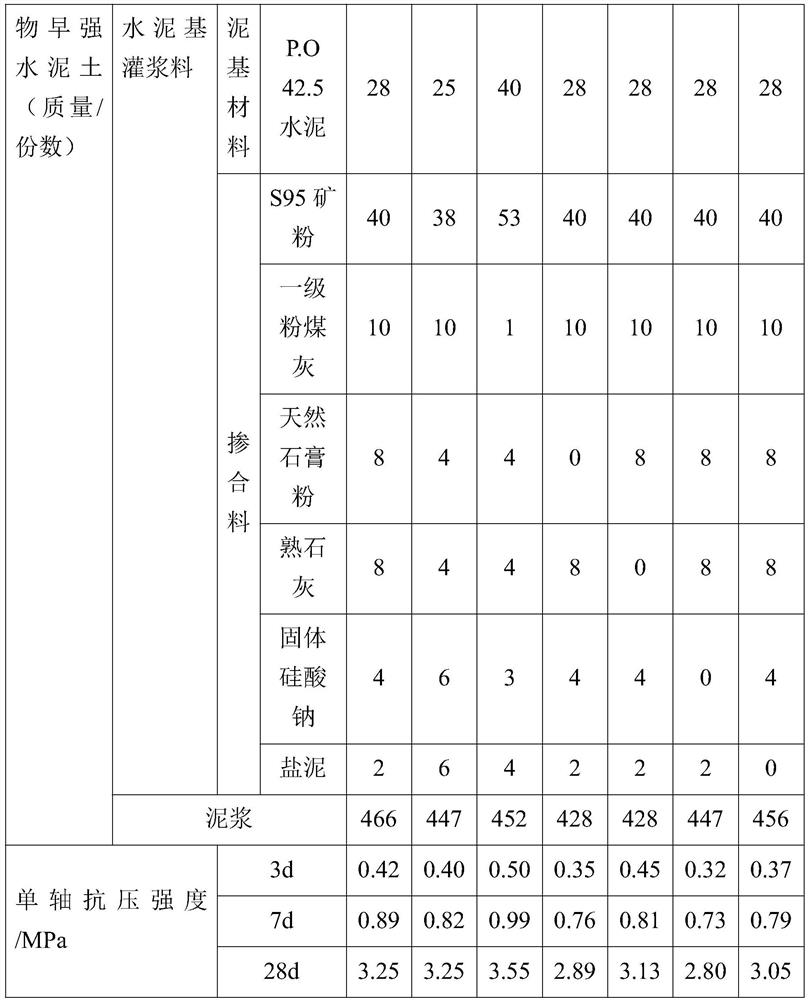

Examples

preparation example Construction

[0027] In the present invention, a kind of preparation method of early-strength cement-based grouting material comprises:

[0028] Put the mineral powder and fly ash into a high-speed pulverizer after mixing them first, and grind for 30 minutes. The grinding method is: grind for 5 minutes and stop for 1 minute to obtain mineral powder-fly ash micropowder (material A). The speed of the high-speed pulverizer is 5200r / min, and the fineness of the output is less than 6um.

[0029] Then dry the natural gypsum powder and salt mud in a constant temperature oven at 105°C for 5 hours, and then grind the natural gypsum powder and salt mud in a pulverizer until the fineness is less than 10um.

[0030] Then, the finely ground mineral powder—fly ash micropowder (A material), gypsum powder, salt mud, and slaked lime are mixed, hydrated, aged, calcined, and ground to prepare B material, and the mixture (B material) is finely ground. The degree is less than 10um.

[0031] Finally, mix P.042...

Embodiment 1

[0041] Mix 40 parts of mineral powder and 10 parts of fly ash into a high-speed pulverizer and grind for 30 minutes. The grinding method is: grind for 5 minutes and stop for 1 minute to obtain mineral powder—fly ash fine powder (material A) , the speed of the high-speed pulverizer is 5200r / min, and the fineness of the output is less than 6um.

[0042] Dry 8 parts of natural gypsum powder and 2 parts of salt mud in a constant temperature oven at 105°C for 5 hours, and grind them with a pulverizer until the fineness is less than 10um.

[0043] The ground mineral powder-fly ash micropowder (A material), gypsum powder and salt mud, 8 parts of slaked lime are mixed, hydrated, aged, calcined, and ground to prepare material B, and the mixture ( Material B) The fineness is less than 10um.

[0044] Mix and stir 28 parts of cement, material B, and 4 parts of solid sodium silicate to obtain material C, and mix material C according to the water-cement ratio of 1.0 to obtain early-strengt...

Embodiment 2

[0047] Mix 38 parts of mineral powder and 10 parts of fly ash into a high-speed pulverizer, and grind for 30 minutes. The grinding method is: grind for 5 minutes and stop for 1 minute to obtain mineral powder—fly ash fine powder (material A) , the speed of the high-speed pulverizer is 5200r / min, and the fineness of the output is less than 6um.

[0048] Dry 4 parts of natural gypsum powder and 6 parts of salt mud in a constant temperature oven at 105°C for 5 hours, and grind them with a pulverizer until the fineness is less than 10um.

[0049] The ground mineral powder-fly ash micropowder (A material), gypsum powder and salt mud, 4 parts of slaked lime are mixed, hydrated, aged, calcined, and pulverized to prepare material B, and the mixture ( Material B) The fineness is less than 10um.

[0050] Mix and stir 25 parts of cement, material B, and 6 parts of solid sodium silicate to obtain material C, and mix material C according to the water-cement ratio of 1.0 to obtain early-st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com