Lateral wall adherence air adding device of front-back wall face-fired boiler

A technology of hedging combustion and adding devices, which is applied in the direction of combustion methods, combustion equipment, lighting and heating equipment, etc. It can solve the problems of high construction requirements, adverse effects of combustion, damage to water walls, etc., so as to facilitate the adjustment of air volume and avoid direct flushing Wall surface, effect of changing smoke composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

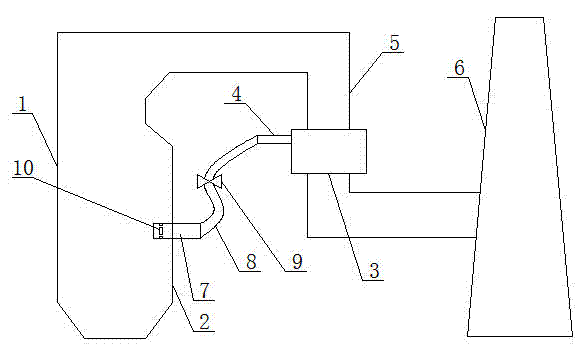

[0012] Such as figure 1 The shown front and rear wall opposed combustion boiler side wall wall-attached air adding device includes a opposed combustion boiler 1, a flue 5 and a chimney 6 at the end of the flue 5, and an air preheater 3 is arranged on the flue 5. On the water wall 2 of the side wall of the opposed combustion boiler 1, there is a wall-adhering air nozzle 7, and the inner end of the wall-adhering air nozzle 7 extends into the opposing combustion boiler 1 by 300 mm, and the inner end of the wall-adhering air nozzle 7 is blocked. A blowing port 10 is provided on the inner peripheral surface of the wall-attached air nozzle 7, and an air protection film is formed on the protected side wall water wall 2 by using the blowing port 10. The outer end of the wall-attached air nozzle 7 is connected with the hot secondary air pipeline 4 of the preheater 3 through a connecting hose 8 . In order to adjust the air volume conveniently, a regulating valve 9 is provided on the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com