Monolithic ceramic electronic component

A technology for electronic components and ceramics, applied in the field of laminated ceramic electronic components, can solve problems such as shortening the distance between internal electrodes, and achieve the effect of preventing the reduction of BDV

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

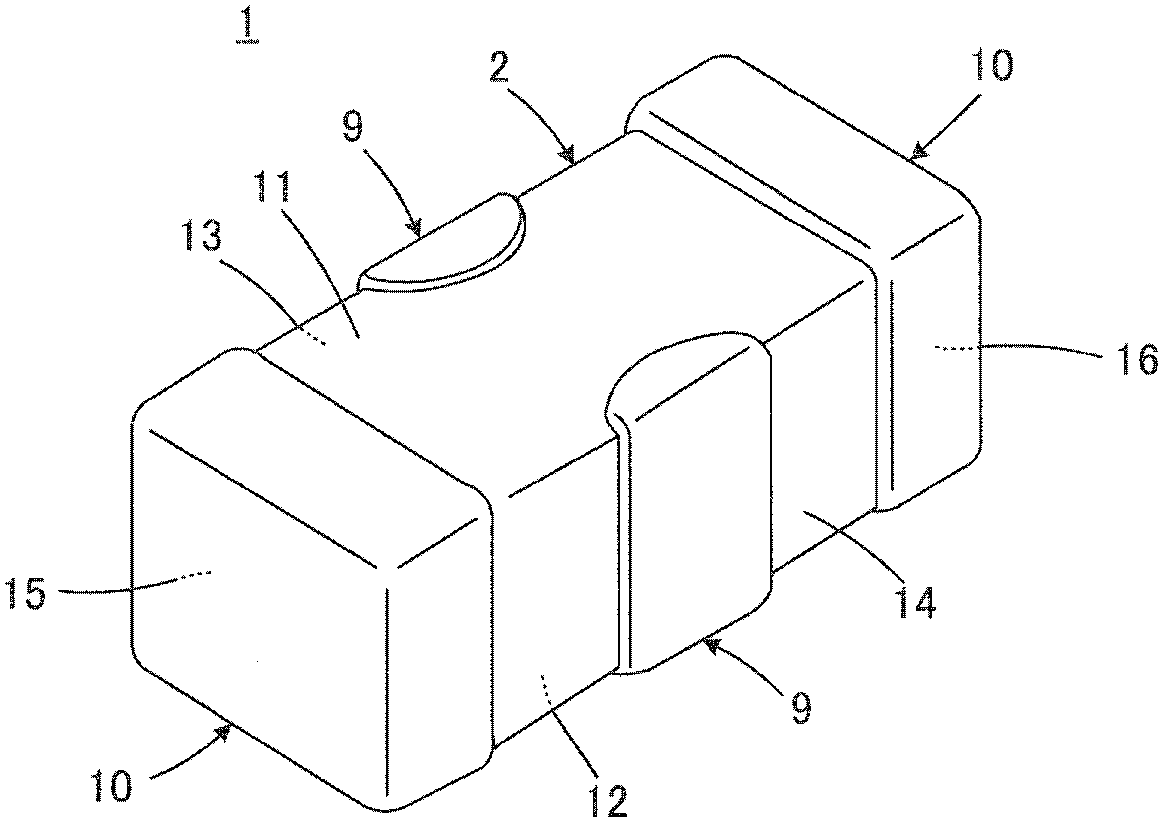

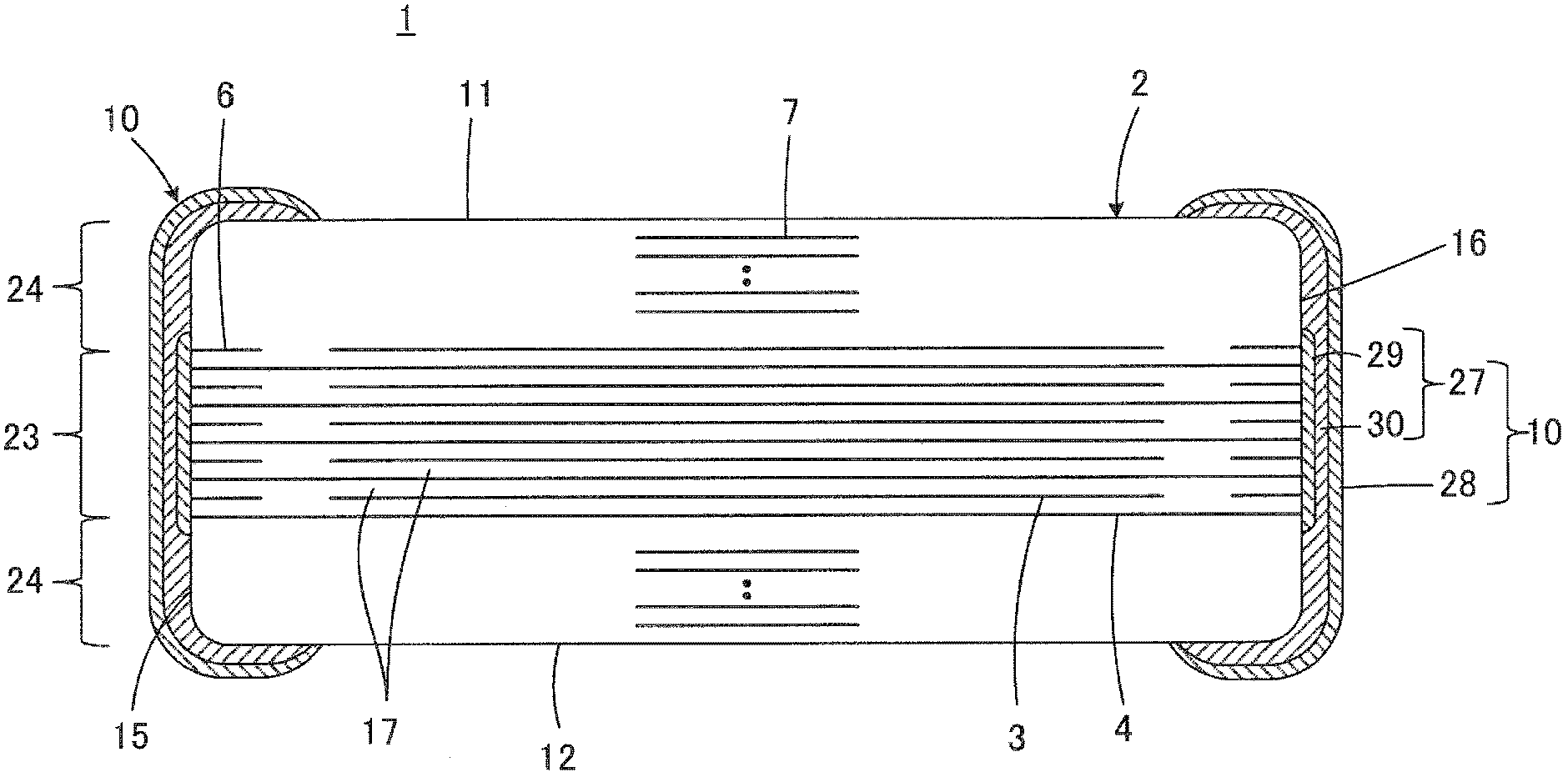

[0043] Figure 1 to Figure 7It is a figure for demonstrating the 1st Embodiment of this invention. The multilayer ceramic capacitor 1 of the first embodiment is a three-terminal type ceramic capacitor. A multilayer ceramic capacitor 1 includes a ceramic body 2; a first internal electrode 3 and a second internal electrode 4, a first inner layer dummy conductor 5 and a second inner layer dummy conductor 6 respectively arranged inside the ceramic body 2; Layer dummy conductor 7 , first external electrode 9 and second external electrode 10 arranged on the outer surface of ceramic body 2 . Hereinafter, the detailed structure of the multilayer ceramic capacitor 1 is divided into (1) a ceramic body, (2) internal electrodes, (3) inner layer dummy conductors, (4) outer layer dummy conductors, and (5) outer electrodes, respectively. (6) The production method will be described below.

[0044] (1) Ceramic body

[0045] The ceramic body 2 is approximately cuboid, and as its outer surfa...

no. 2 Embodiment approach

[0132] The second embodiment of the present invention is as Figure 8 shown. Figure 8 With image 3 corresponding figure. exist Figure 8 in, right with image 3 Elements corresponding to the elements shown are given the same reference numerals, and overlapping description thereof will be omitted.

[0133] In the multilayer ceramic capacitor 1a according to the second embodiment, the outer layer dummy conductors 7a are not formed to penetrate the ceramic green body 2 in the width direction, but are formed separately in the width direction.

no. 3 Embodiment approach

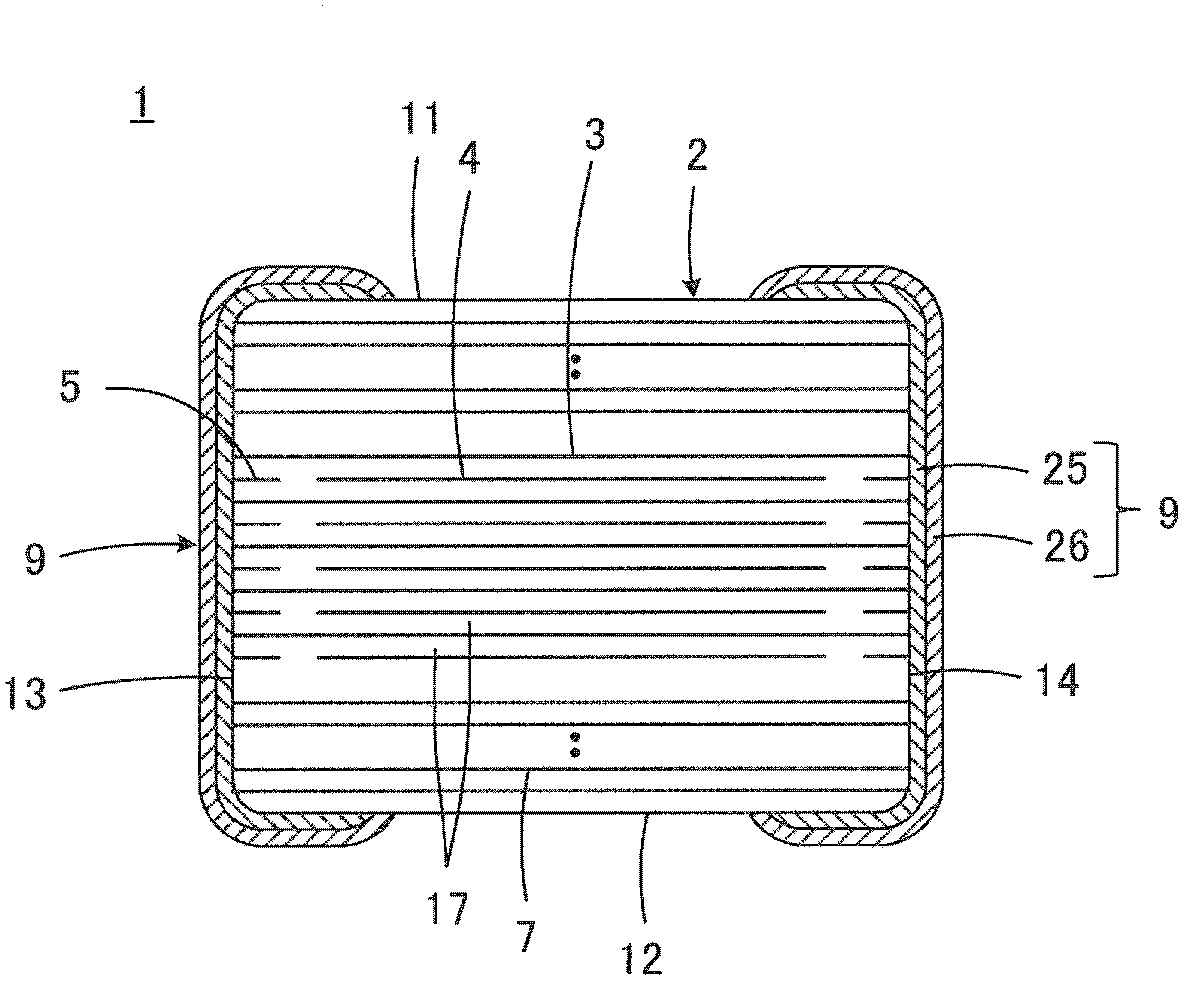

[0135] The third embodiment of the present invention is as Figure 9 as well as Figure 10 shown. Figure 9 With figure 1 corresponding figure, Figure 10 With image 3 corresponding figure. exist Figure 9 as well as Figure 10 in, right with figure 1 as well as image 3 Elements corresponding to the elements shown are given the same reference numerals, and repeated description thereof will be omitted.

[0136] In the multilayer ceramic capacitor 1b according to the third embodiment, the first external electrode 9b includes the base layer 25 and the upper layer 26, and is characterized in that the first side surface 13 and the second side surface 14 surrounding the ceramic body 2 also have a first main surface. 11 and the second main surface 12 are arranged.

[0137] In this embodiment, it is preferable to remove the ceramic layer 17 to be the main surface 11 and the main surface 12 by the aforementioned polishing step after firing, and to make the outer layer dummy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com