Electric cable connection terminal and wire harness having the electric cable connection terminal

A cable connection and cable technology, applied in the direction of conductive connection, multi-core cable end parts, connection, etc., can solve the problem of increased contact resistance of the connection part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

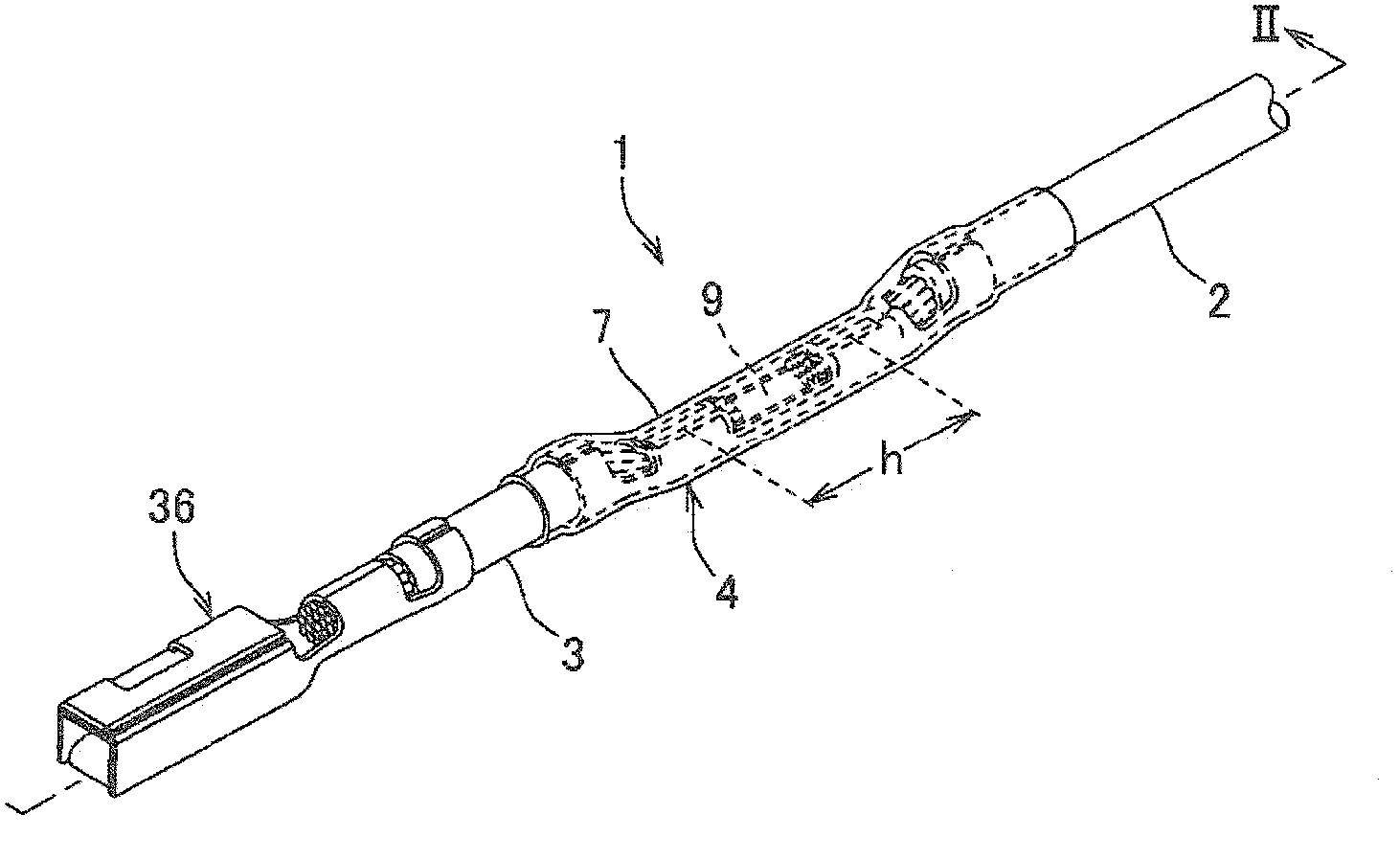

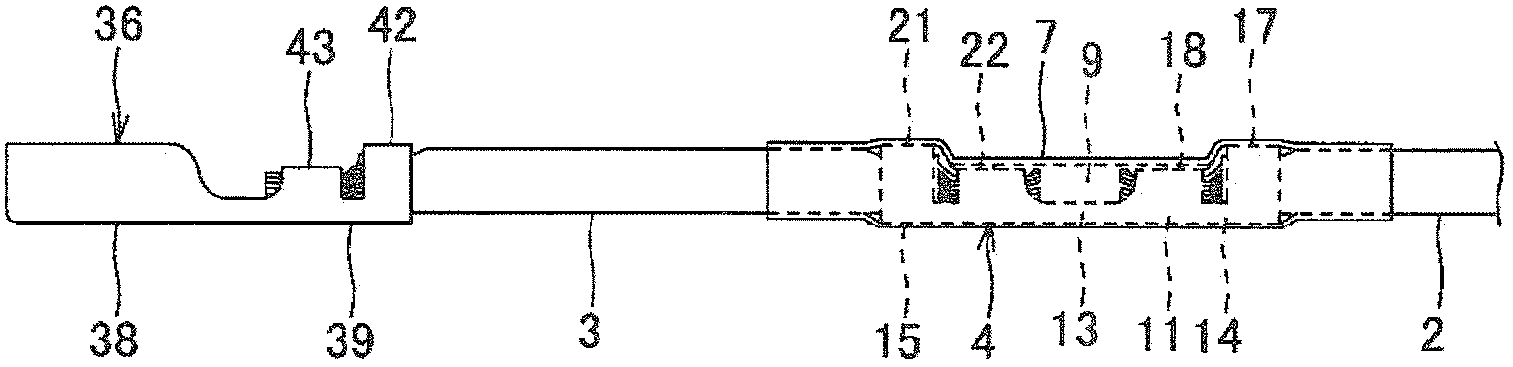

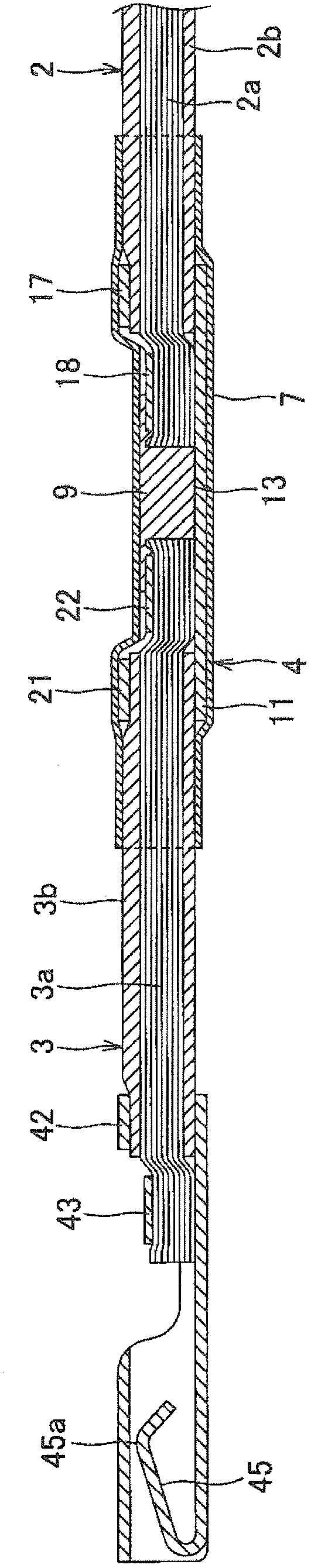

[0030] In the following, we will combine Figures 1 to 7 An illustrative embodiment of the present invention will be described.

[0031] Such as figure 1 As shown in , a wire harness 1 having a cable connection terminal 4 according to an illustrative embodiment of the present invention has: an aluminum cable 2 as one cable; a copper cable 3 as another cable; and a cable connection terminal 4, the The cable connection terminal electrically connects the aluminum cable 2 and the copper cable 3 .

[0032] Such as image 3 As shown in , the aluminum cable 2 has a conductive core wire 2a and an insulating covering portion 2b. The core wire 2a is formed by twisting a plurality of conductive wires. The wires are made of aluminum or aluminum alloys. The covering portion 2b is made of synthetic resin such as polyvinyl chloride resin. The covering portion 2b covers the core wire 2a. Meanwhile, the core wire 2a may also consist of a single electric wire.

[0033] The aluminum cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com