Directional electromagnetic steel plate and method for manufacturing same

一种电磁钢板、制造方法的技术,应用在制造工具、无机材料磁性、激光焊接设备等方向,能够解决激光到达功率减少、加工效率降低等问题,达到抑制电绝缘性的降低、生产率高、优异铁损特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, preferred embodiments of the present invention will be described with reference to the attached drawings.

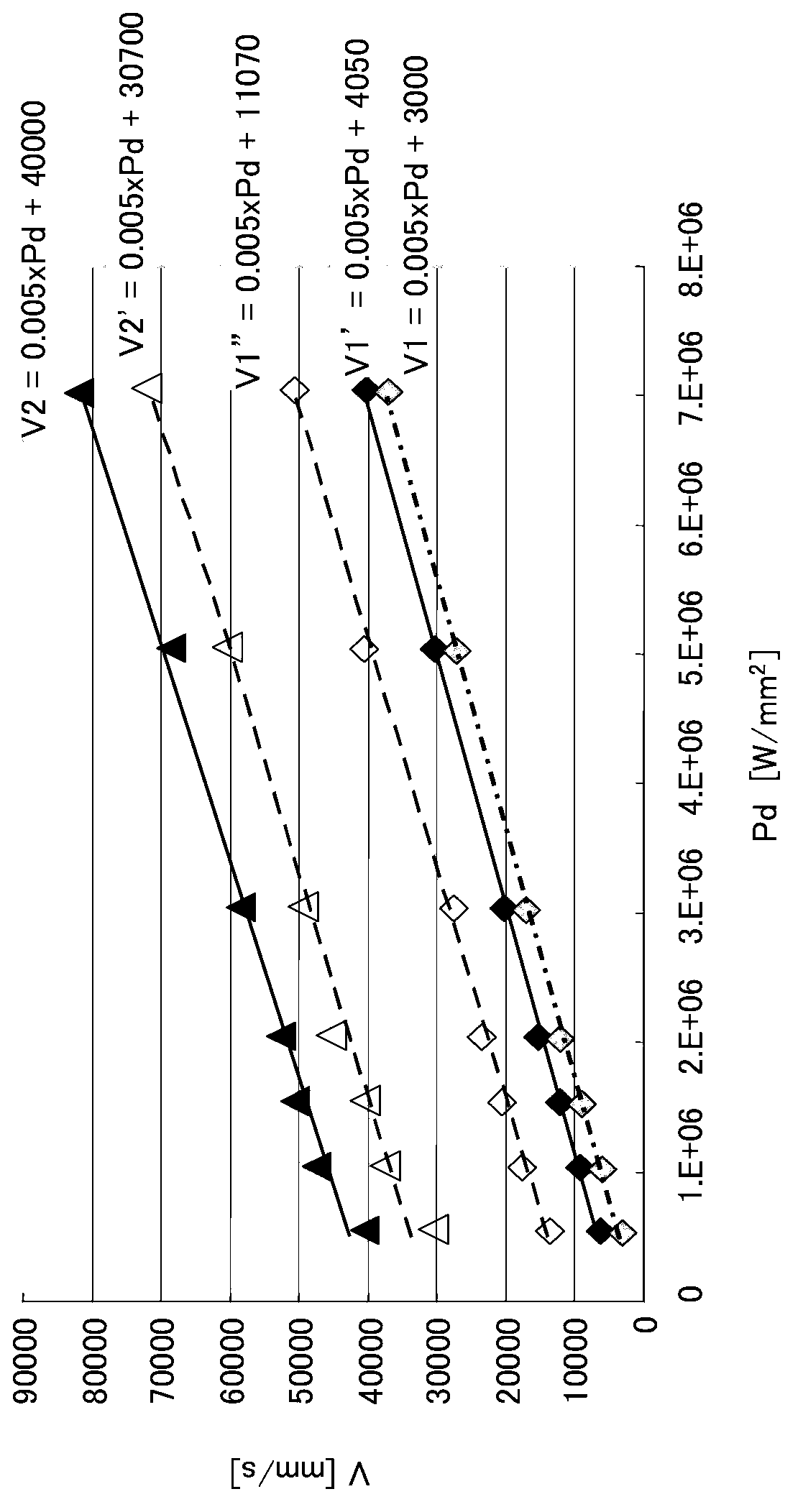

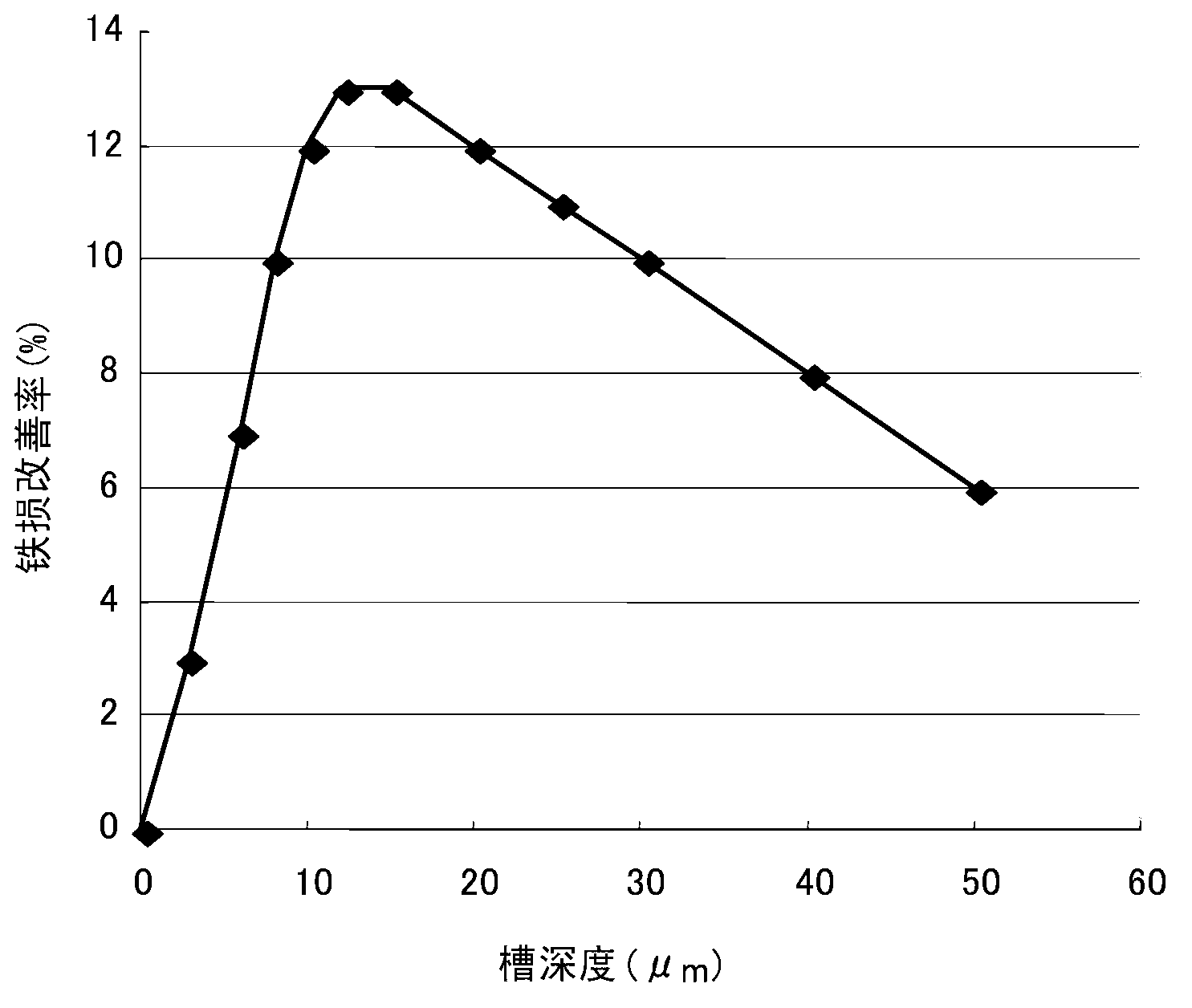

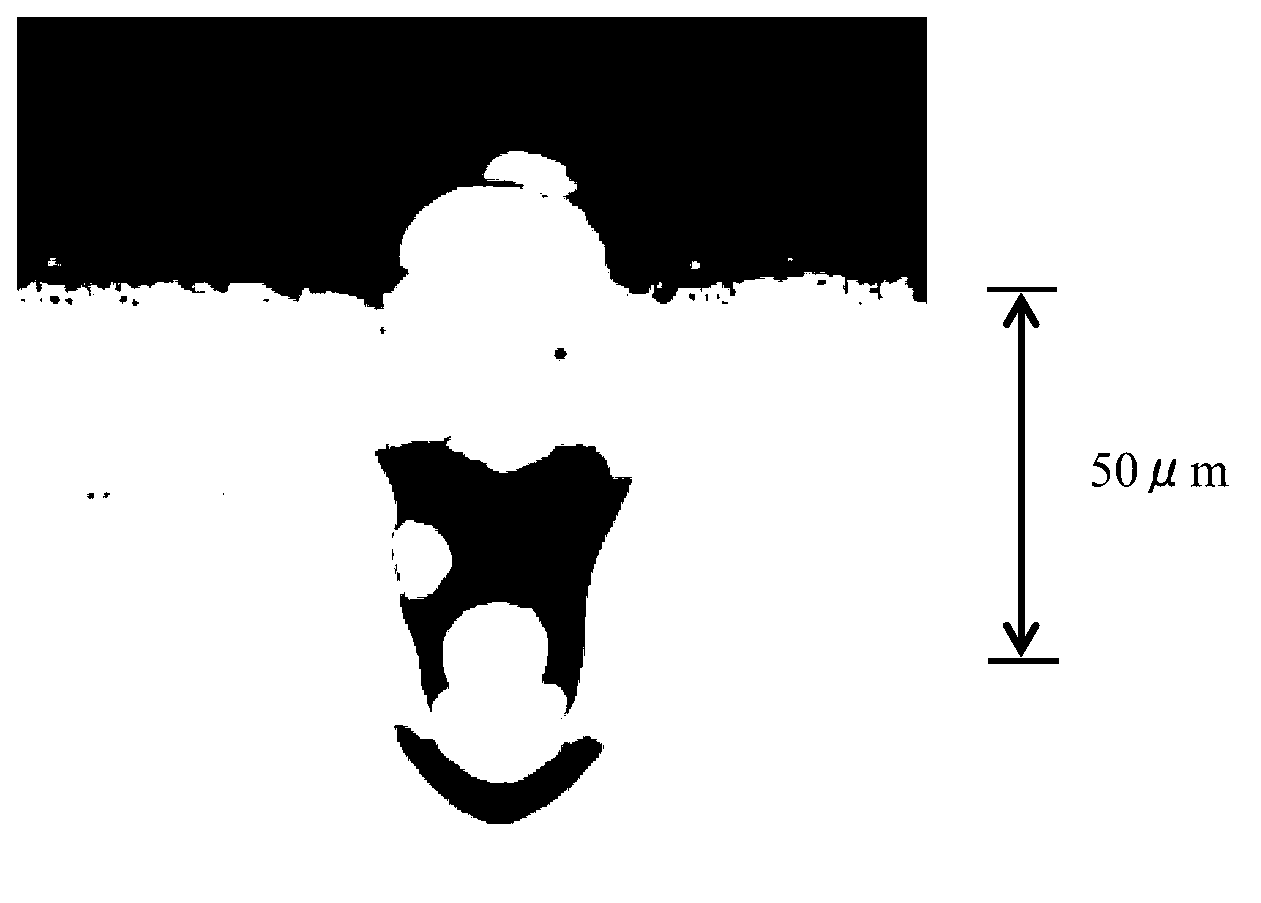

[0047] The inventors of the present invention have intensively studied the mechanism by which surface protrusions (protrusions, fusion protrusions) of a grain-oriented electrical steel sheet are generated when laser beams are irradiated. As described above, when the laser beam is irradiated, the laser beam is absorbed on the surface of the steel sheet, the base metal of the steel sheet is melted, and fine molten droplets are scattered. This melt is scattered by the pressure of high-temperature metal vapor or plasma at the processing point (laser beam irradiation point). Conventionally, in order to form grooves in grain-oriented electrical steel sheets, CO 2 laser. proceed with CO 2 In experiments in which a laser was used as a light source to form grooves in a grain-oriented electrical steel sheet, the melting phenomenon was studied in detail, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com