Blade-free automatic copying fish scale scraper

A bladeless and scale-free technology, which is applied in the direction of fish cleaning / descaling, can solve the problems of sharp blade processing hazards, affecting efficiency, large labor force, etc., and achieve the effect of long processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

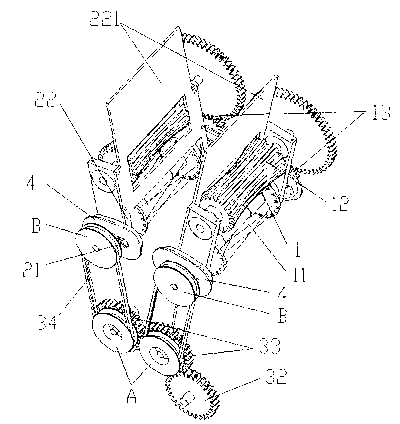

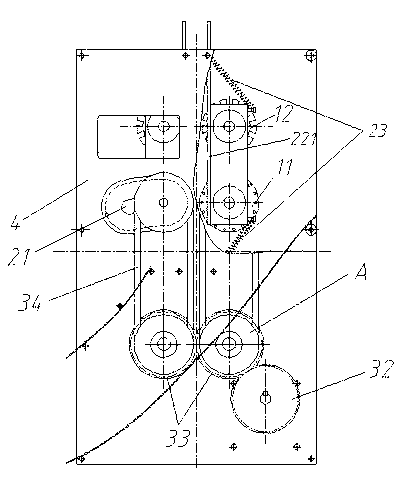

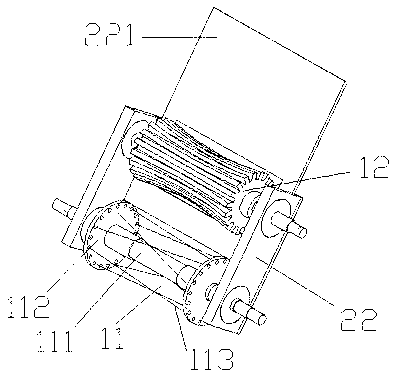

[0021] A bladeless automatic profiling fish scale scraper, including a frame, is characterized in that it also includes a descaling device 1, a swing mechanism 2 and a power transmission mechanism 3;

[0022] The power transmission mechanism includes a motor 31 arranged on the frame 4, the output shaft gear 32 of the motor 31 is engaged with a gear in a pair of intermeshing gear sets 33, and the gear set is passed through a pair of gears integrated with it. The pulley A and the belt transmission mechanism 34 are connected with the swing mechanism 2 and realize the transmission;

[0023] Described oscillating mechanism comprises a pair of arc groove 21 that is located on the frame 4, the rotating shaft of another pair of pulleys B in the described belt conveying mechanism 34 passes through arc groove 21, and a pair of pulley B is connected with respectively A pair of descaling rollers 11 of the descaling device 1 are coaxially connected;

[0024] The descaling device 1 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com