Method for controlling injection flow through pressure test

A technology for injection flow and pressure testing, which is applied in the directions of measurement, fluid extraction, earthwork drilling, etc., can solve problems such as increased construction costs, hidden safety hazards, and adjustment of injection and production flow in wells, so as to save construction costs, save labor time, The effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

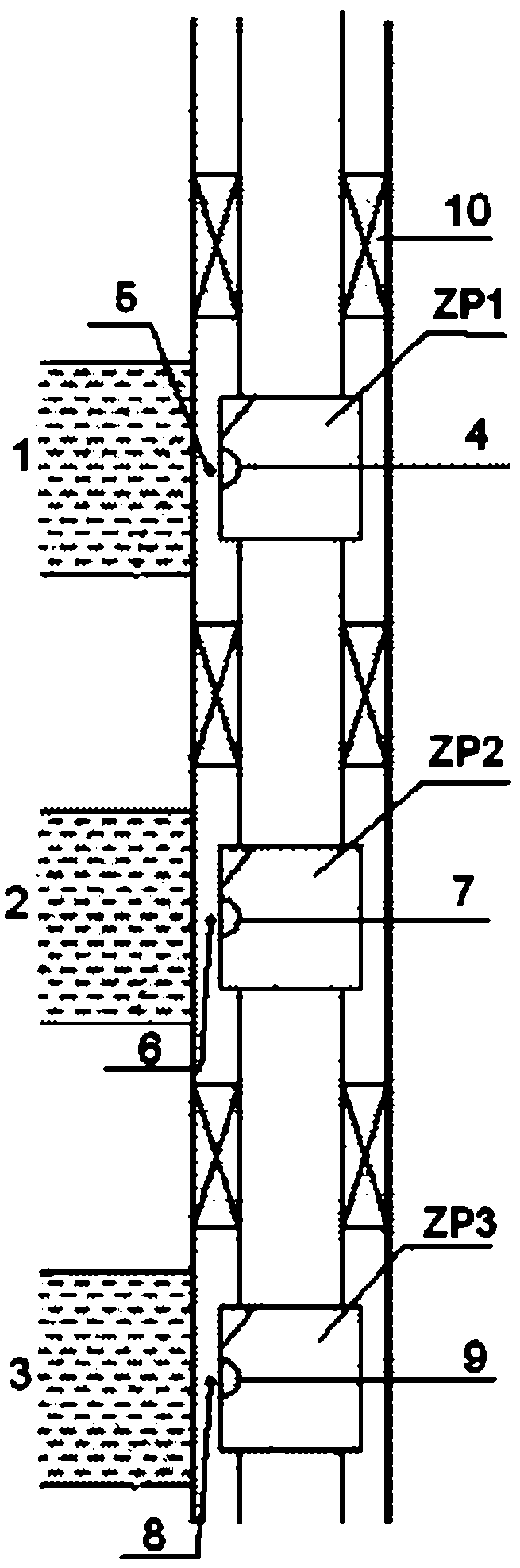

[0025] A method for controlling the injection flow rate by pressure testing, the method is to adjust and control the stratified water injection volume by measuring and controlling the mouth pressure of an intelligent water distributor in a stratified water injection well;

[0026] The method firstly adjusts the openings of the faucets of the intelligent water distributors on each layer in order to stabilize the pump pressure of the ground water injection pump and stabilize the flow rate of the ground water injection at the pre-allocation flow rate of each layer. At this time, the faucet is recorded and stored The opening degree of the faucet and the pressure value behind the nozzle under the opening degree of the faucet; the recorded pressure value behind the nozzle corresponds to a fixed faucet opening degree and the actual water injection volume; The device automatically adjusts its water nozzle to the recorded opening corresponding to the pressure value behind the nozzle, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com