Online type high voltage silicon rubber material detection apparatus

A detection device, high-voltage silicon technology, applied in the direction of optical testing flaws/defects, etc., can solve problems such as destructiveness, inability to grasp the instantaneous failure of the outer insulating silicone rubber material in time, and inability to detect the same material for a long time, to ensure safe operation. , easy to deal with in a timely manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

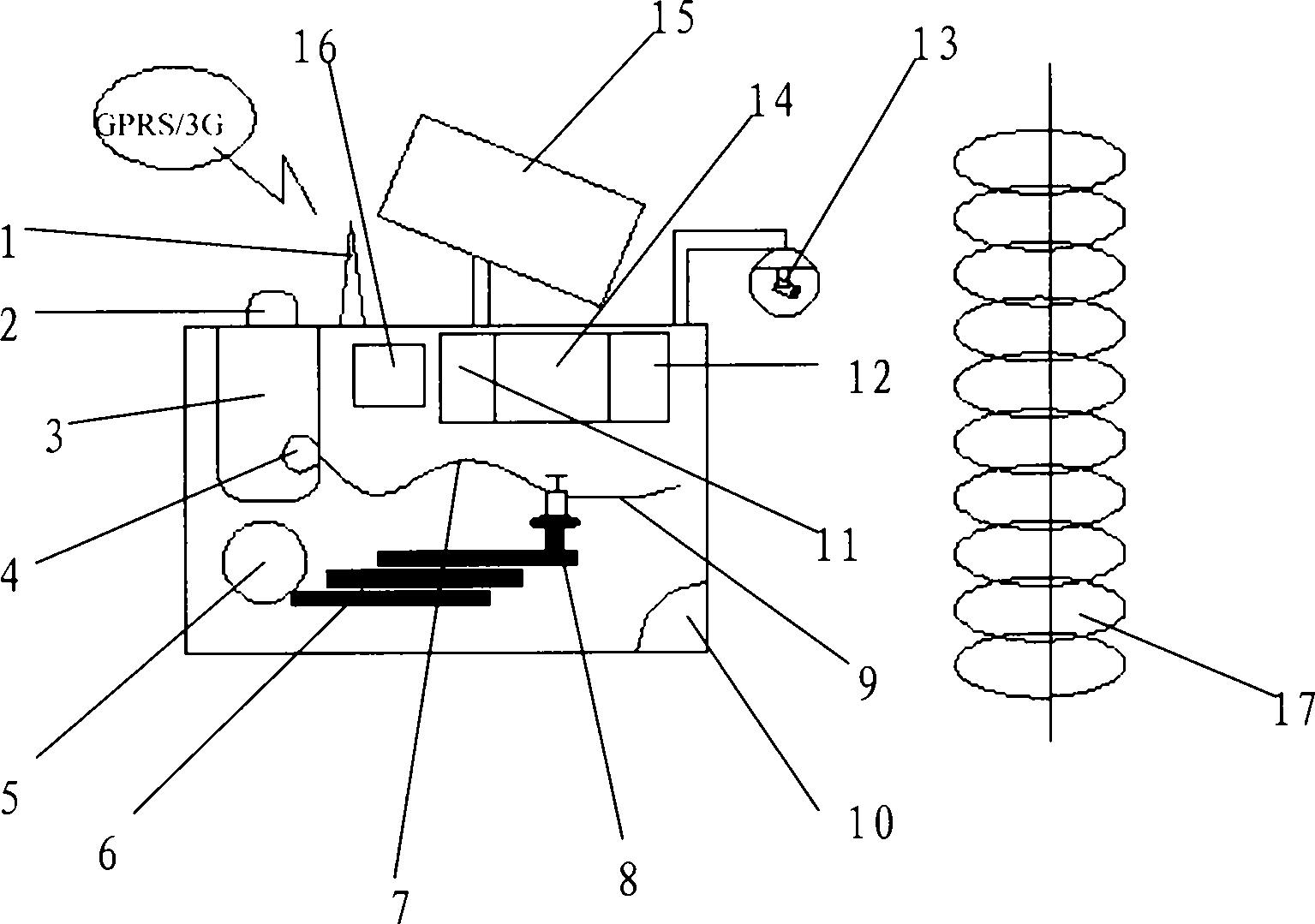

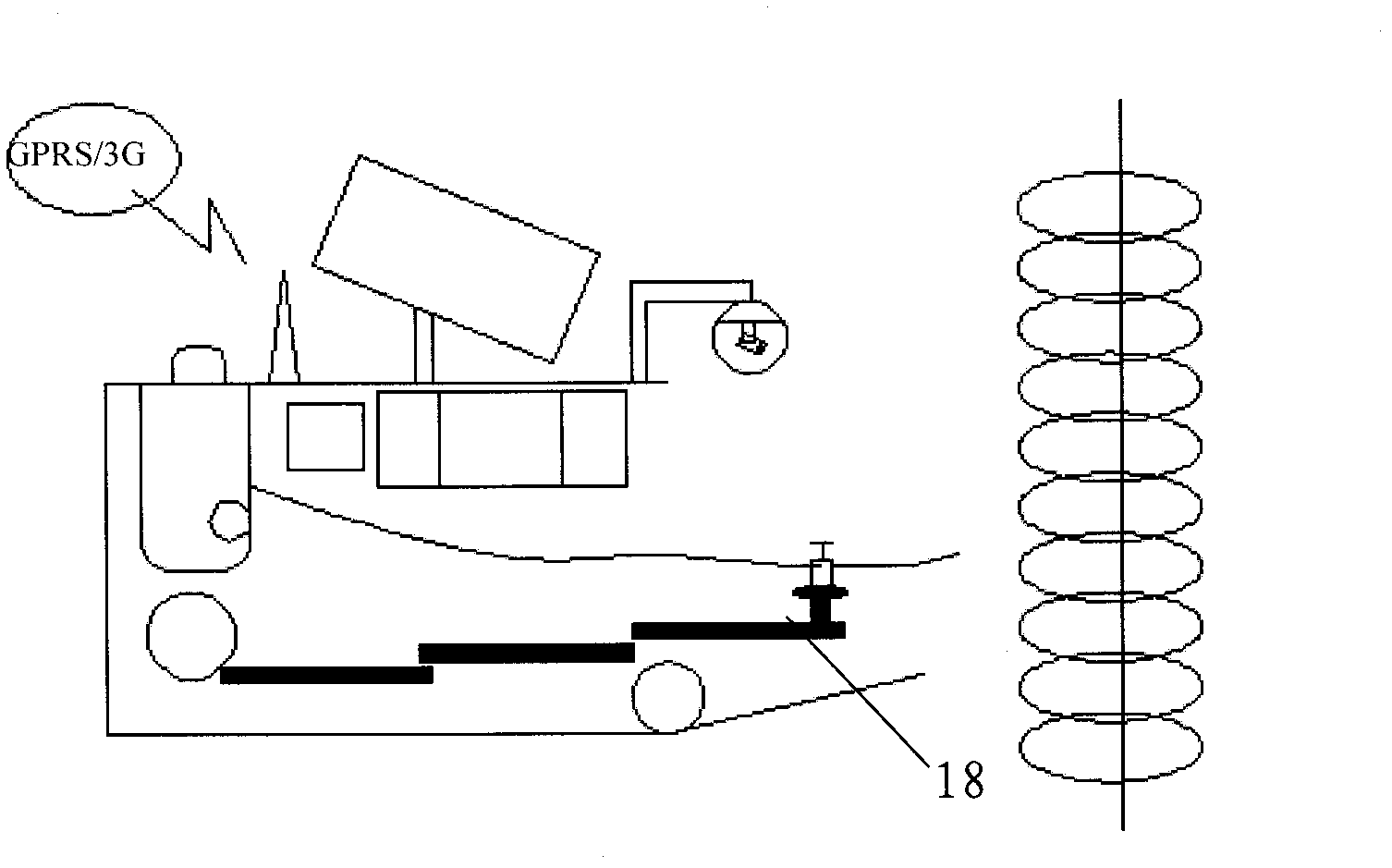

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0012] Such as figure 1 , figure 2 As shown, an on-line high-voltage silicon rubber material detection device provided by an embodiment of the present invention includes a GPRS antenna (1), a water inlet (2), a water tank (3), a water shortage monitoring float (4), a sliding rail driver (5), slide rail (6), outlet pipe (7), water spray valve (8), insulated water spray gun (9), box door driver (10), GPRS communication board (11), cloud Platform camera slide rail control panel (12), pan-tilt camera (13), core control panel (14), solar panel (15), storage battery (16) and box door (18).

[0013] A GPRS antenna (1), a water inlet (2), a pan-tilt camera (13) and a solar panel (15) are fixedly installed on the outside of the box, and a water tank (3), a slide rail driver (5), a sliding Track (6), water outlet pipe (7), water spray valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com