Flexible replaceable screw thread pair driving ultrasonic motor

An ultrasonic motor, screw pair technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc. and other problems, to achieve the effect of improving output performance, promoting practical process, and enriching reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

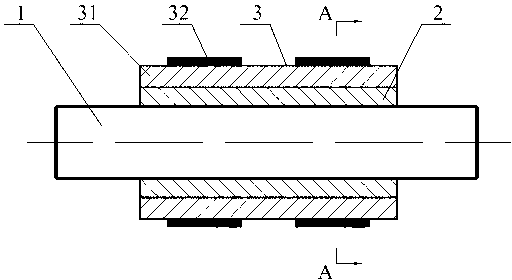

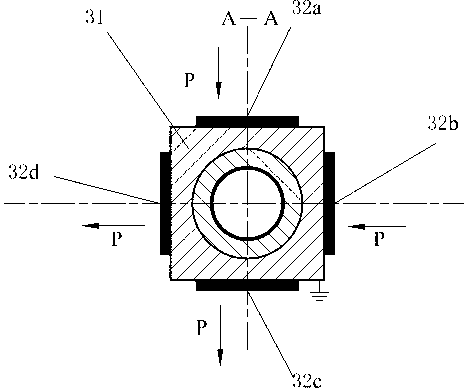

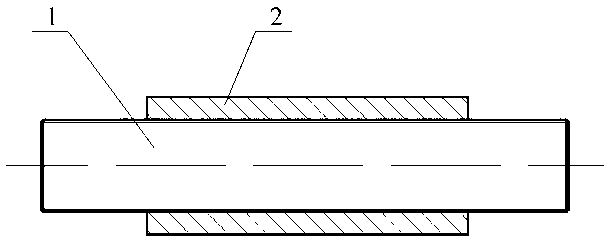

[0035] Specific implementation mode one: see Figure 1 to Figure 8 , a flexible and replaceable screw drive ultrasonic motor, the ultrasonic motor includes a screw output shaft 1, a replaceable screw drive element 2 and an ultrasonic excitation vibrator 3, the shape of the replaceable thread drive element 2 is cylindrical, and the ultrasonic excitation vibrator 3. It consists of an excited body 31 and at least four exciting elements 32. At least four flat sides or grooves with a symmetrical structure and a square orientation are uniformly processed on the peripheral side of the excited body 31 (such as figure 2 and Figure 8 The structure of the groove makes the structure of the ultrasonic excitation vibrator 3 more compact, the number of the excitation element 32 is the same as that of the flat side or the groove, and an excitation element 32 is consolidated on each flat side or in the groove (by cold welding or ring Oxygen resin glue consolidation), the outer surface of ...

specific Embodiment approach 2

[0042] Specific implementation mode two: see Figure 9 to Figure 16 , a flexible and replaceable threaded auxiliary driving ultrasonic motor, the ultrasonic motor includes a threaded output shaft 1, an ultrasonic excitation vibrator 3 and two replaceable threaded auxiliary driving elements 2, the shape of the replaceable threaded auxiliary driving element 2 is cylindrical, and the ultrasonic The exciting vibrator 3 is composed of an excited body 31 and at least four exciting elements 32, and at least four flat sides or grooves with a symmetrical structure and a square orientation are uniformly processed on the peripheral side of the excited body 31 (such as Figure 10 and Figure 16 , the groove structure makes the structure of the ultrasonic excitation vibrator 3 more compact), the number of the excitation element 32 is the same as that of the flat side or the groove, and one excitation element 32 is consolidated on each flat side or in the groove (by cold welding or ring ...

specific Embodiment approach 3

[0050] Specific implementation mode three: see Figure 17 to Figure 20, a flexible and replaceable threaded auxiliary driving ultrasonic motor, the ultrasonic motor includes a threaded output shaft 1, an ultrasonic excitation vibrator 3 and two replaceable threaded auxiliary driving elements 2, and the shape of the replaceable threaded auxiliary driving element 2 has a cone angle of θ is in the shape of a truncated cone, and the ultrasonic excitation vibrator 3 is composed of an excited body 31 and at least four exciting elements 32, and at least four symmetrical flat sides or Groove, the vibration element 32 has the same number as the flat side or the groove, and one vibration element 32 is fixed on each flat side or in the groove (consolidated by cold welding or epoxy resin), and it is fixed in the groove. The outer surface of the excitation element 32 in the groove is lower than or flush with the side of the excited body 31 where the groove is located, and a mounting hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com