Method for processing double-color Oreal wool fabric

A color velvet and processing method technology, applied in the direction of fabric surface trimming, heating/cooling fabric, textile material treatment, etc., can solve the problems that cannot be removed, easy to breed bacteria, and the degree of non-slip is not obvious, etc., to achieve good surface plumpness High degree, ideal anti-deformation ability, excellent anti-skid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

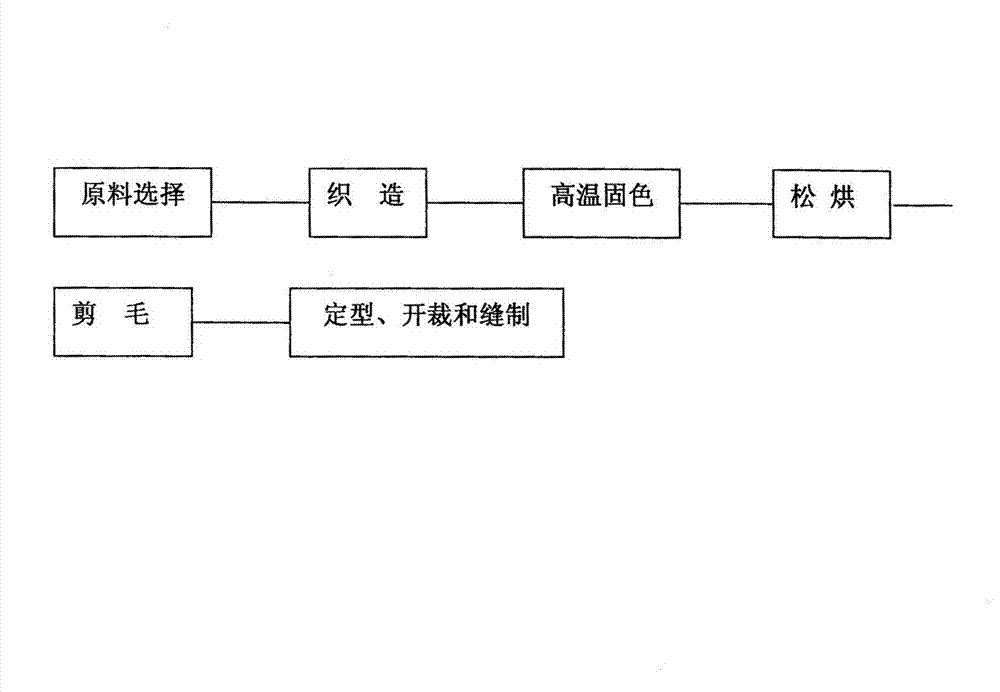

[0021] according to figure 1 Process flow shown.

[0022] A) Raw material selection, choose 300D / 72F polyester yarn and 300D / 96F polyester cationic yarn as the top yarn at the same time, and choose 150D / 48F polyester low-stretch yarn as the bottom yarn, in which the top yarn is in the two-color Ollie fleece fabric The mass percentage accounted for is 80%, while the mass percentage occupied by the bottom yarn is 20%, the mass percentage of the 300D / 72F polyester yarn in the face yarn is 60%, and the 300D / 96F The mass percentage of the polyester cationic yarn in the face yarn is 40%;

[0023] B) Weaving, put the surface yarn and bottom yarn obtained in step A) into the weft knitting machine for one-time weaving. The weft knitting machine is a cut loop pile machine. 6 polyester yarns of 300D / 72F, and the other way is 6 polyester cationic yarns of 300D / 96F, so that they are spaced apart, and the rotating speed of the weft knitting machine is 10n / min to obtain gray cloth; ...

Embodiment 2

[0029] Only change the mass percentage of the face silk in step A) to 90%, change the mass percentage of the bottom thread to 10%, and change the mass percentage of the polyester cationic silk of 300D / 72F and 300D / 96F in the face thread Change it to 40% and 60% respectively; change the speed of the weft knitting machine in step B) to 5n / min; change the color fixing temperature in step C) to 130°C, the pressure to 0.25MPa, and the holding time to 25min; change the drying temperature in step D) to 175°C, and the cloth speed to 14m / min; change the setting temperature in step F) to 150°C, and the cloth speed to 14m / min, after cutting and sewing After making, the two-color velvet fabric with a wool height of 4mm, a width of 1.7m and a grammage of 600g / ㎡ was obtained, and the rest were the same as those described in Example 1.

Embodiment 3

[0031] Only change the mass percentage of the face yarn in step A) to 70%, change the mass percentage of the bottom yarn to 30%, in the bottom yarn, the mass percentage of the polyester yarn of 300D / 72F and the polyester cationic yarn of 300D / 96F Change to 50% each; change the speed of the weft knitting machine in step B) to 22n / min; change the color fixing temperature in step C) to 100°C, change the pressure to 0.15MPa, and change the holding time to 40min; In step D), the loosening temperature is changed to 150°C, and the cloth speed is changed to 10m / min; in step F), the setting temperature is changed to 160°C, and the cloth speed is changed to 15m / min. After cutting and sewing, the obtained Gross height is 6mm, width is 1.65m and grammage is the two-color velvet fabric of 630g / ㎡, and all the other are the same as the description to embodiment 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com