Catalytic agent for preparing ethanol by using acetic acid hydrogenation and preparation method thereof

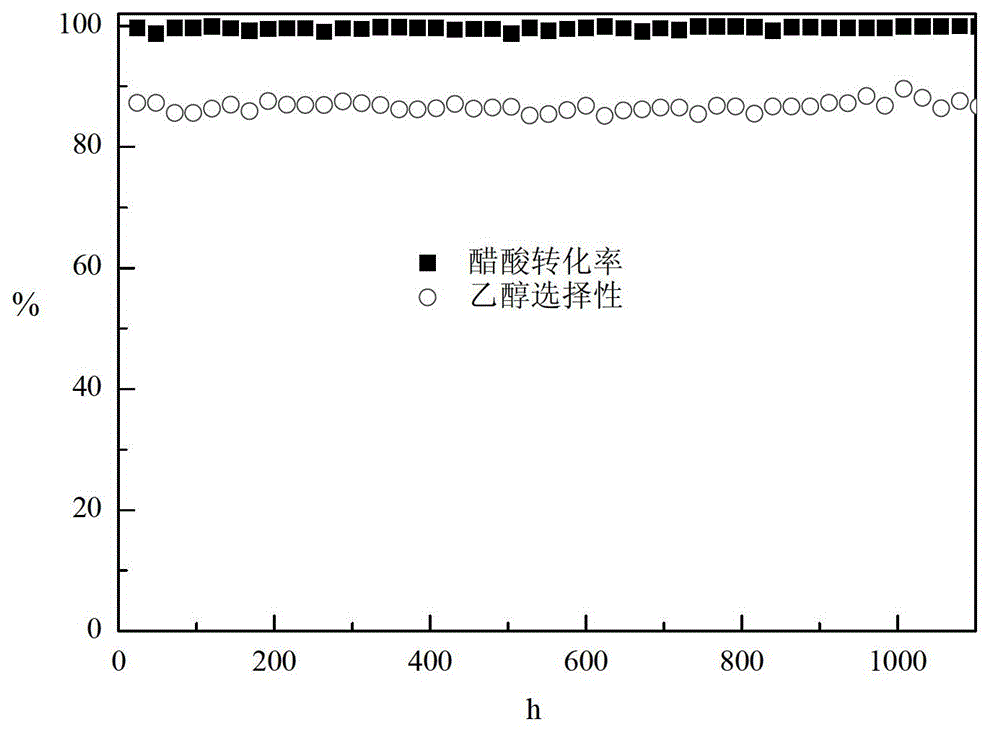

A catalyst and ethanol production technology, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as restricting industrial applications, and achieve the effects of inhibiting corrosion, small activity changes, and inhibiting catalyst deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

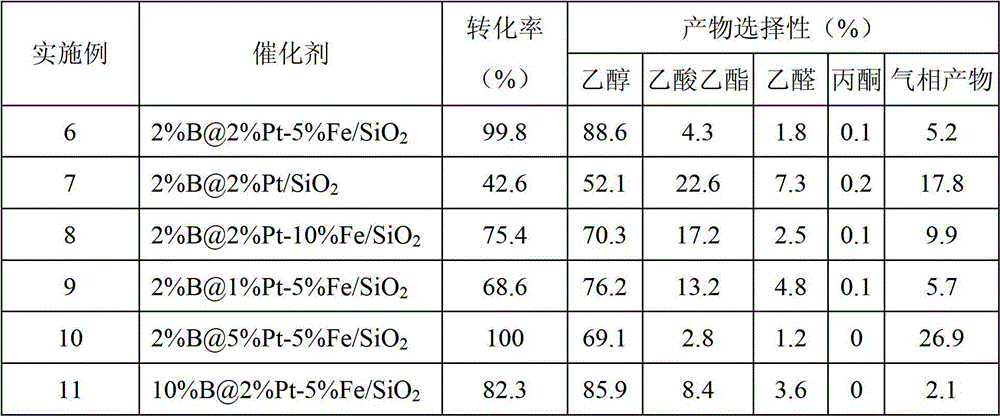

[0029] 2%B2%Pt-5%Fe / SiO 2 catalyst:

[0030] 1) The purchased commercial SiO 2 (specific surface area 270m 2 / g) 5.0g was refluxed with 100mL of 5% dilute nitric acid in an oil bath at 100°C for 24h, filtered, washed and dried. Weigh 1.0g of treated SiO 2 Add it to 30mL deionized aqueous solution, and ultrasonically disperse for 1h to obtain suspension A.

[0031] 2) Dissolve 6.6mL of 3mg / mL chloroplatinic acid aqueous solution and 0.721g of ferric nitrate in 50mL of water, mix them evenly, add them to suspension A, and stir at room temperature for 24h.

[0032] 3) The solution in step 2) was stirred and evaporated to dryness in an oil bath at 90°C to obtain solid B.

[0033] 4) Solid B was calcined at 500 °C for 4 h to obtain solid C.

[0034] 5) Dissolve 0.22 g of boric acid in 50 mL of deionized aqueous solution, add to solid C, disperse by ultrasonic for 1 h, then stir and evaporate to dryness in an oil bath at 90°C to obtain solid D.

[0035] 6) Calcining the solid...

Embodiment 2

[0041] 2%B2%Pt-5%Fe / SiC catalyst:

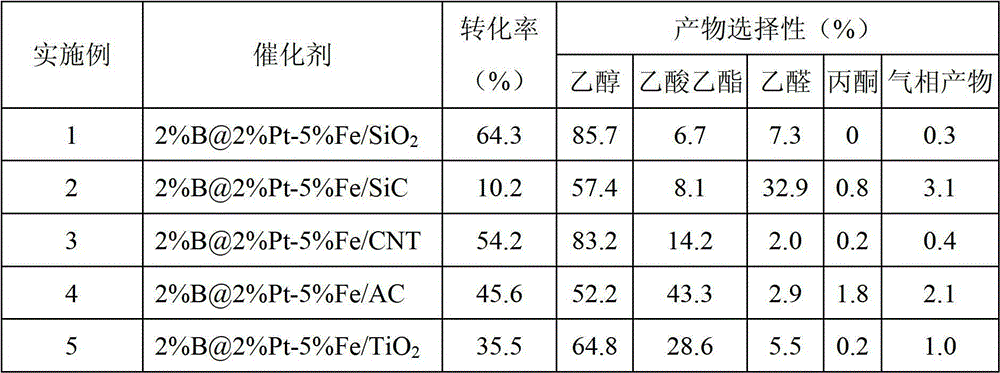

[0042] The preparation method of silicon carbide supported Pt-Fe-B catalyst is the same as embodiment 1, just SiO 2 Change to SiC carrier, and silicon carbide needs to be baked at 800°C for 4h before use. The 2%B2%Pt-5%Fe / SiC catalyst was prepared, and the performance evaluation and product analysis conditions of the catalyst for the hydrogenation of acetic acid to ethanol were the same as in Example 1, and the results are shown in Table 1.

Embodiment 3

[0044] 2%B2%Pt-5%Fe / CNT catalyst:

[0045] The preparation method of carbon nanotube supported Pt-Fe-B catalyst is the same as embodiment 1, just SiO 2 The CNT (carbon nanotube) carrier was replaced to prepare a 2%B2%Pt-5%Fe / CNT catalyst. The performance evaluation and product analysis conditions of the catalyst for the hydrogenation of acetic acid to ethanol were the same as in Example 1. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com