On-site Welding Method of Steel Lining Panel in Nuclear Power Plant

A technology for steel lining and nuclear power plants, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as difficult to guarantee welding quality, heavy welding workload, poor working conditions, etc., to improve welding quality and efficiency, and installation time The effect of shortening, improving ergonomics and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The on-site welding method for the steel lining wallboard of the nuclear power plant in this embodiment adopts argon tungsten arc welding machine and carries out the following steps:

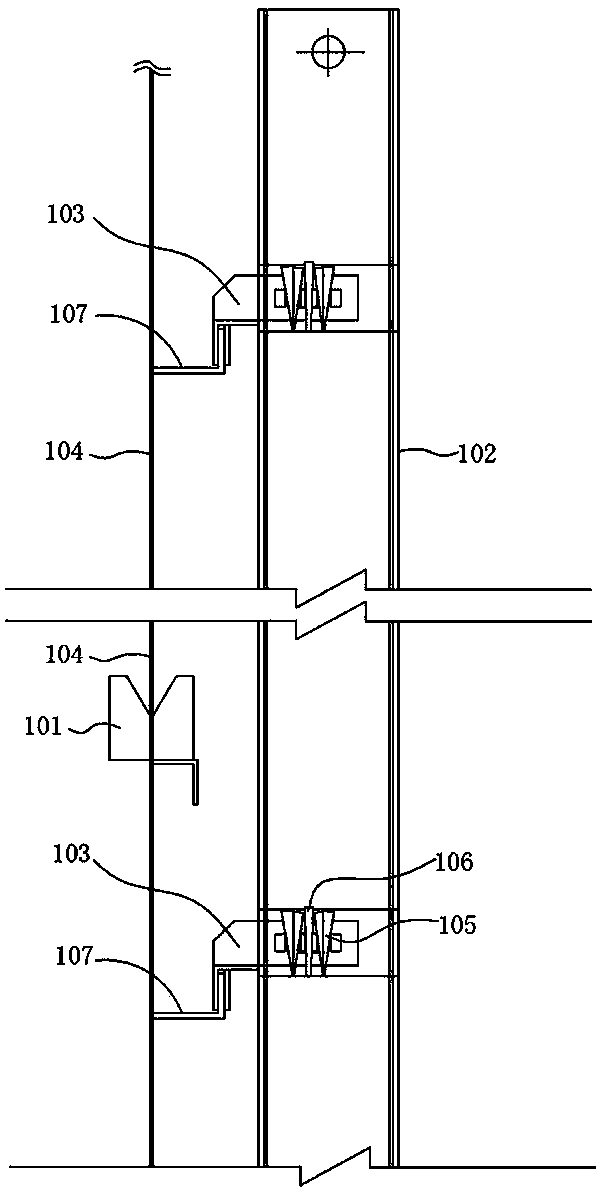

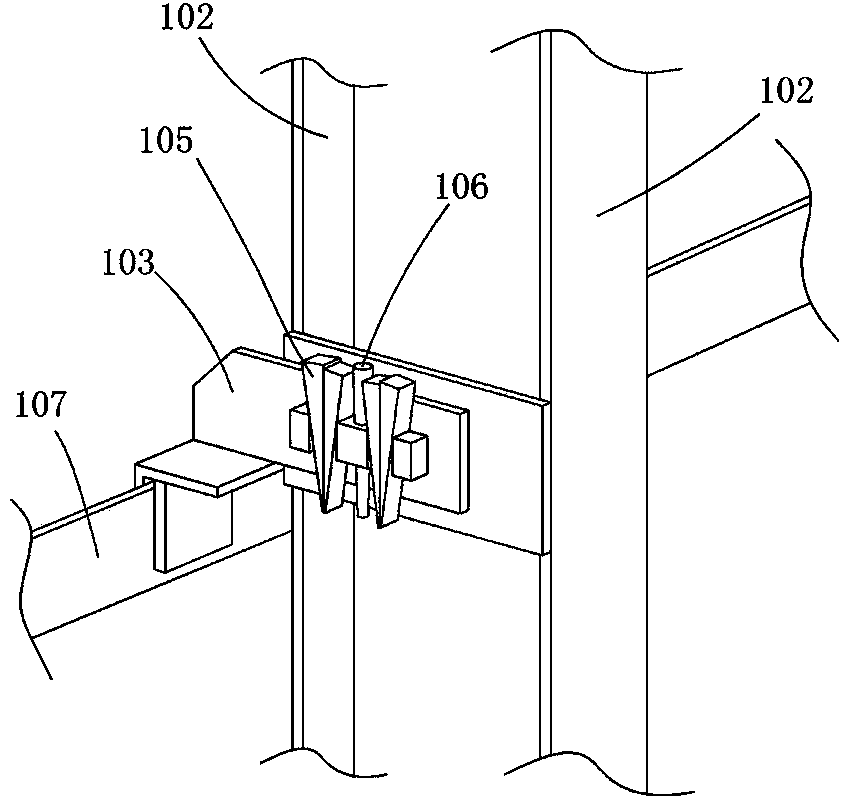

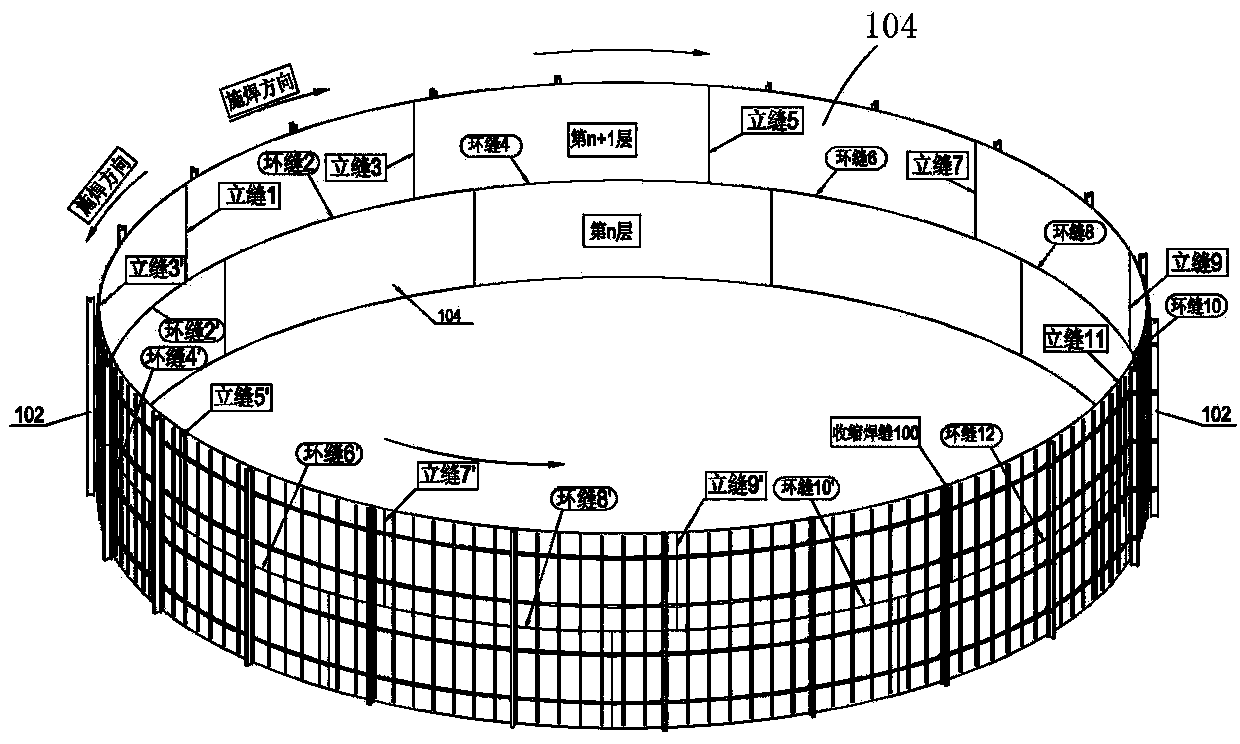

[0035] 1) Assemble the steel-lined panel 104 in place by tooling. Specific as figure 1 with figure 2 As shown, the tooling that present embodiment adopts is guide plate 101, buttress column 102, spectacle plate 103, wedge 105 and bearing pin 106, at first lift and fix buttress column 102 by spectacle plate 103, wedge 105 and pin shaft 106 in the next On the large angle steel 107 of the steel lining wall plate of the first layer; then a pair of guide plates 101 are paired and spot welded on the upper opening of the next layer of wall plate at an interval of about 1m in the circumferential direction; finally, the steel lining wall plate 104 is hoisted, and the upper and lower layers of steel lining wall plates 104 close to each other through the guide plate 101, and through the buttress ...

Embodiment 2

[0049] The on-site welding method of the steel lining panel of the nuclear power plant in this embodiment is basically the same as that in Embodiment 1, except that the main welding process parameters of the automatic full welding in step 3) are different, as shown in Table 2 below:

[0050] Table 2

[0051]

Embodiment 3

[0053] The on-site welding method of the steel lining wall plate of the nuclear power plant in this embodiment is basically the same as that in the first embodiment, except that the main welding process parameters of the automatic full welding in step 3) are different, as shown in Table 3 below:

[0054] table 3

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com