Wave blade-shaped end mill processing method

A processing method and end mill technology, applied in the field of mechanical processing tools, can solve the problems of easy loss of service life, insufficient chip removal, and low work efficiency, and achieve the goals of reduced cutting resistance, smooth chip removal, and improved processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

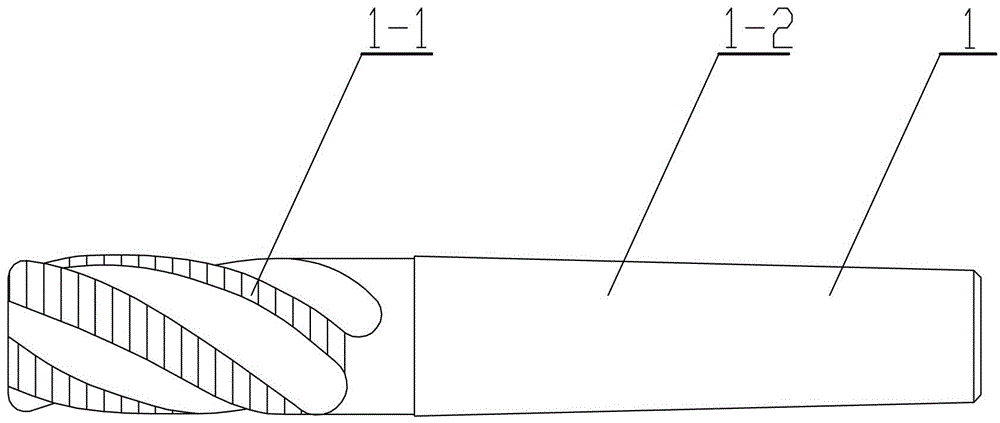

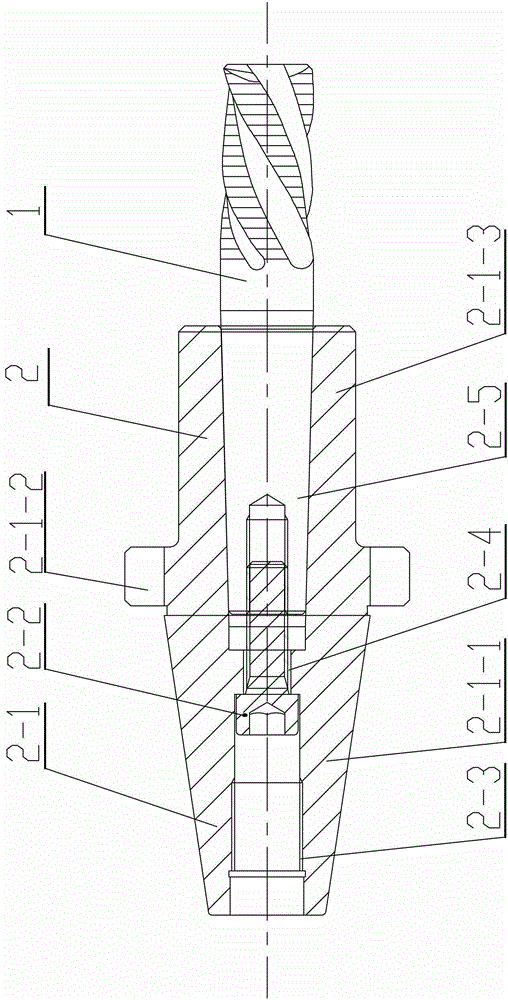

[0018] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, the special fixture 2 used in the processing method of wave-blade end mills in this embodiment includes a clamp body 2-1 and a tension screw 2-2, and the clamp body 2-1 is made of a cone 2-1-1, the annular boss 2-1-2 and the cylinder 2-1-3 are sequentially formed and made into an integrated rotary body, the large diameter end of the cone 2-1-1 and the annular boss 2-1 One end of -2 is fixedly connected, and the other end of the annular boss 2-1-2 is fixedly connected with one end of the cylinder 2-1-3, and the inside of the clamp body 2-1 is connected from the small part of the cone 2-1-1. The other end of the diameter end to the cylinder 2-1-3 is sequentially processed with a connected M24 threaded hole 2-3, a Φ18 hole 2-4 and a Mohs No. 4 inner hole 2-5, and the tension screw 2-2 passes through the The M24 threaded hole 2-3 is detachably connected to the clamp body 2-1; ...

specific Embodiment approach 2

[0027] Specific implementation mode two: combination figure 2 This embodiment will be described. In this embodiment, the taper of the clamp body is 7:24. This setting can make the wave-blade end mill 1 be positioned in the spindle hole of the five-axis CNC grinding machine with high precision, which is more conducive to realizing the purpose of the present invention. The other method steps are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: combination figure 2 This embodiment is described. In this embodiment, the tension screw 2-2 is an M16 tension screw. The application of the M16 tension screw in the present invention can achieve the best inventive effect, and the other method steps are the same as those of the specific embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com