Comprehensive waste wire recovery platform

A platform, waste wire technology, applied in the direction of conveying filamentous materials, conveyors, thin material processing, etc., can solve the problems of difficult emptying operation of waste wire I-shaped wheels, low safety factor, low emptying efficiency, etc., and achieve compact arrangement. , Easy to disassemble, easy to empty and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

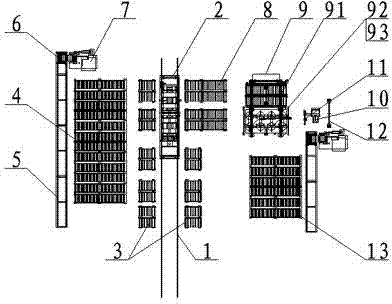

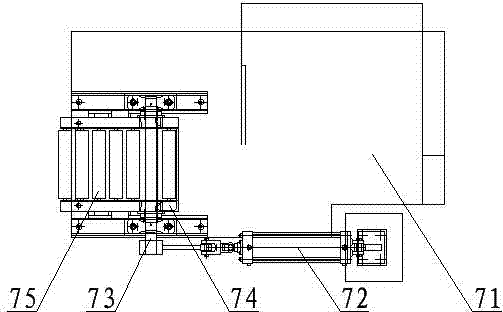

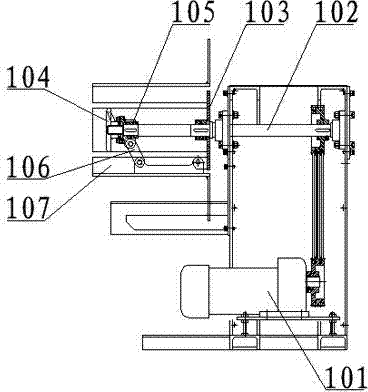

[0030] figure 1 As shown, a waste silk comprehensive recovery platform includes a workshop track 1, a transport trolley 2, an I-shaped wheel tray 3, a platform to be recovered 4, a trolley track 5, a trolley 6, an overturning device 7, a pay-off roller table 8, and a pay-off roller. Device 9 , emptying machine 10 , polished rod liner 11 , broken wire protection device 12 and recovered platform 13 . In the multi-workshop, there are multiple workshop tracks 1 that are sequentially or cross-connected with each other. On the workshop track 1, there are transport trolleys 2 that can move along the workshop tracks; The trolley 6 that can move along the trolley track 5 is arranged on the track 5, and the turning device 7 corresponding to the trolley 6 is arranged outside the trolley track 5; the platform 4 to be recovered and the recovered platform 13 are more than one roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com