High-strength anti-stripping castable with homogeneous material as aggregate for kilneye and preparation method thereof

The technology of castable and homogenized material is applied in the field of high-strength anti-spalling castable for kiln mouth and its preparation, and achieves the effects of superior mechanical properties and superior spalling properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

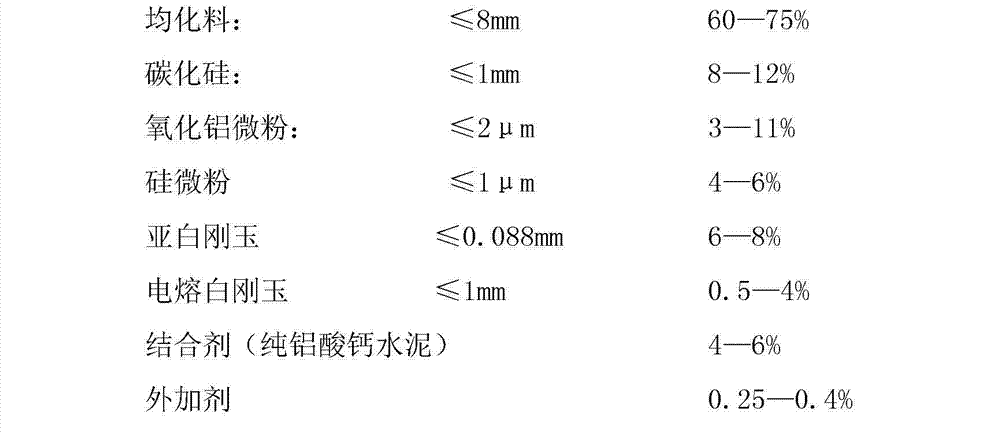

[0019] For the high-strength anti-stripping castable for the kiln mouth where the homogenized material is aggregate and the preparation method, the proportioning raw materials of each component are proportioned according to the following proportions:

[0020]

Embodiment 2

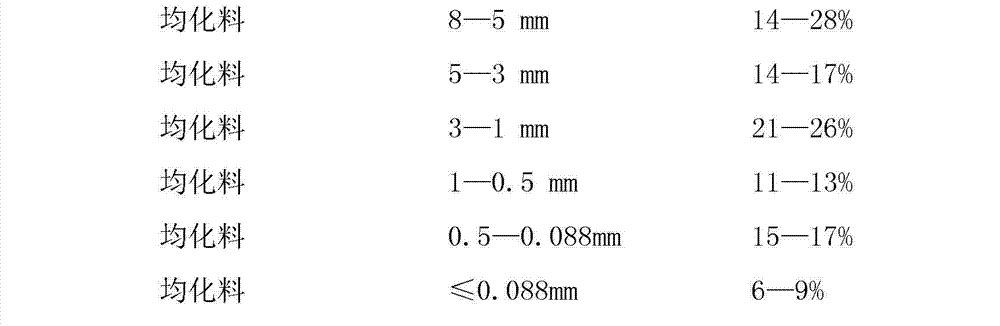

[0022] For the high-strength anti-stripping castable for the kiln mouth where the homogenized material is aggregate and the preparation method, the proportioning raw materials of each component are proportioned according to the following proportions:

[0023]

[0024]

Embodiment 3

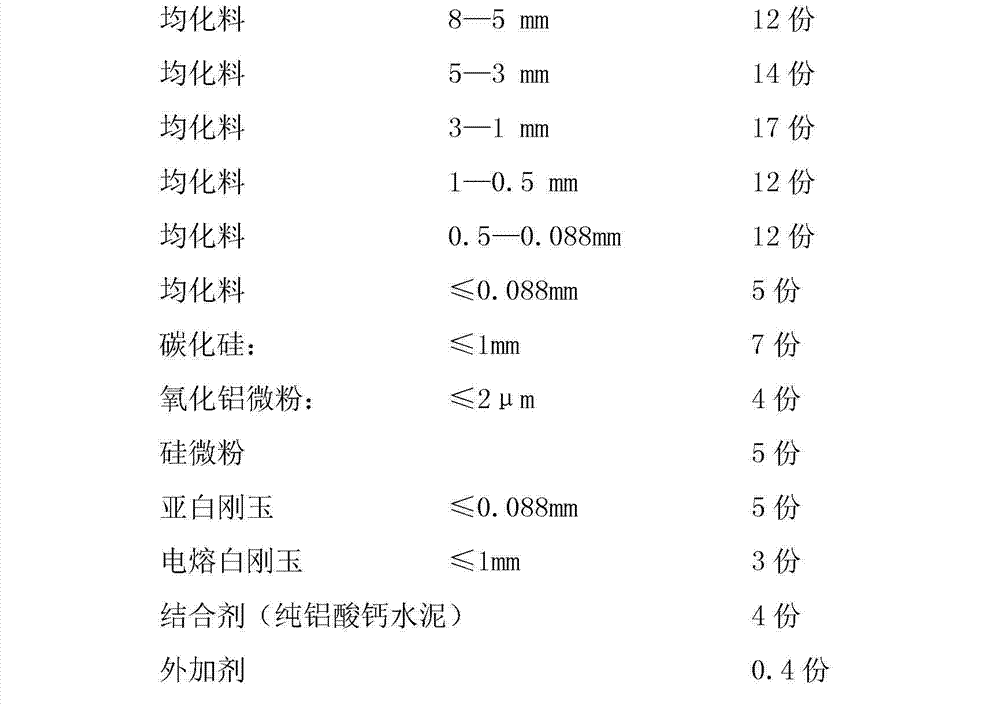

[0026] For the high-strength anti-stripping castable for the kiln mouth where the homogenized material is aggregate and the preparation method, the proportioning raw materials of each component are proportioned according to the following proportions:

[0027]

[0028] The performance parameters of the refractory castable made of the above combination ratio are as follows:

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com