Preparation method of low-compression and permanent-deformation microcellular polyurethane elastomer

A microcellular elastomer and permanent deformation technology, which is applied in the field of preparation of microcellular elastomer materials, can solve the problems of poor compression permanent deformation performance of polyurethane microcellular elastomers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

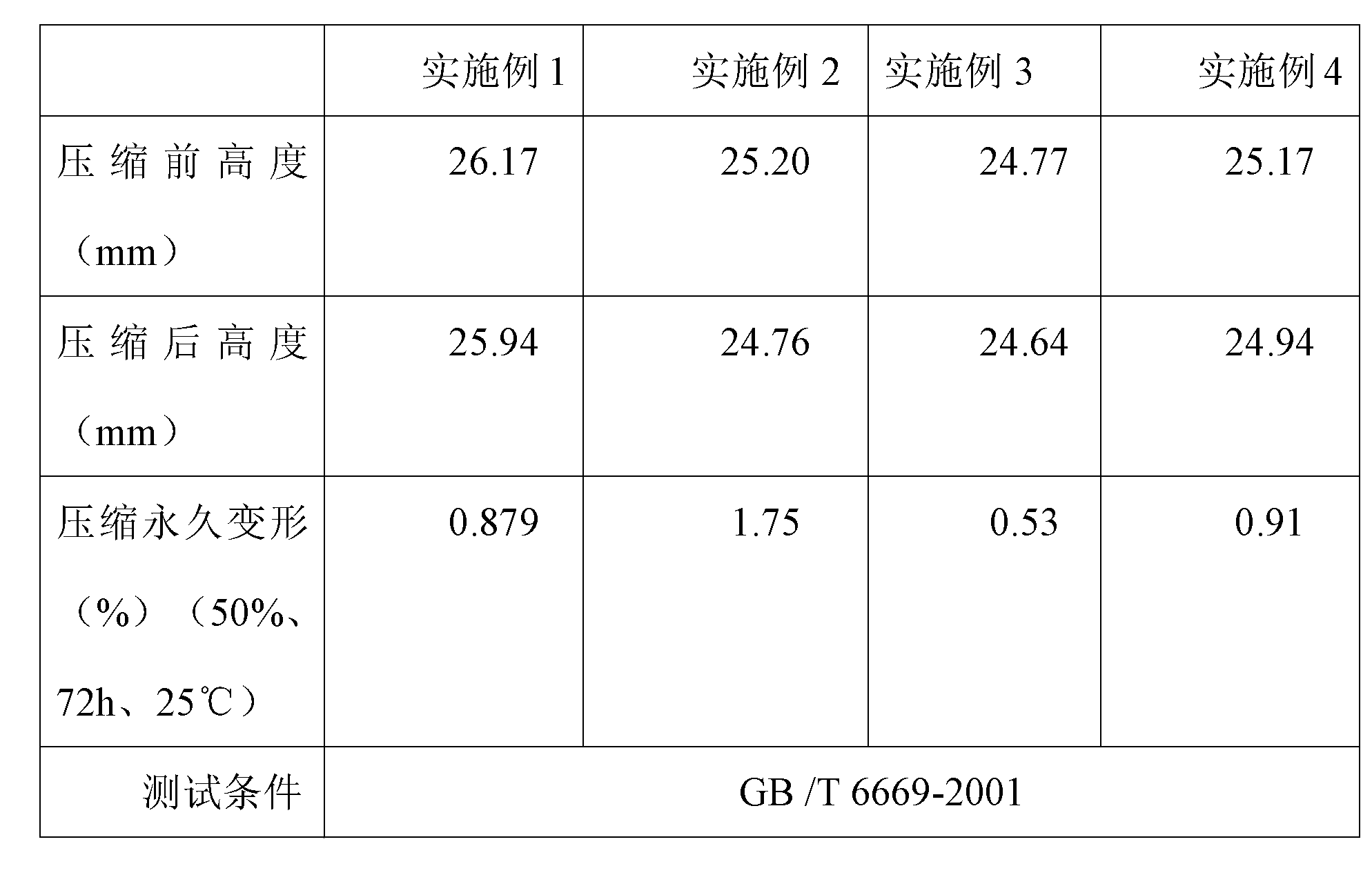

Examples

preparation example Construction

[0021] The invention provides a method for preparing a polyurethane microcellular elastomer with low compression set, comprising the steps of:

[0022] Step 1: react the polymer polyol with p-phenylene diisocyanate at 70-80°C to obtain a prepolymer, and the -NCO group content in the prepolymer is ≤6.2%;

[0023] Step 2: mixing polyol, blowing agent, catalyst 1, catalyst 2 and surfactant in a mass ratio of 100: 4-8: 0.8-1.2: 0.4-0.6: 2-6 to obtain a chain extender; The polyhydroxyl compound includes 10% to 35% polyester polyol, 50% to 75% glycol and 2% to 35% crosslinking agent by weight, and the catalyst 1 is organic carboxylic acid Dialkyltin salt, catalyst 2 is an amine catalyst;

[0024] Step 3: Mix the prepolymer obtained in step 1 with the chain extender obtained in step 2, stir evenly to obtain a mixed material, vulcanize and demould the mixed material to obtain a product;

[0025] Step 4: Post-vulcanize the product obtained in Step 3 to obtain a polyurethane microcell...

Embodiment 1

[0037] Place 100 g of polycaprolactone with a number average molecular weight of 1000 in a 1-liter three-necked bottle, set the temperature to 100°C, remove the water in the polycaprolactone polyol in a vacuum environment, and lower the temperature to 70°C , under the protection of nitrogen atmosphere, add 32g of p-phenylene diisocyanate into the three-necked flask, stir at a speed of 1000rmp for 2.5h, and calibrate the prepolymer-NCO% content of 6.2%;

[0038] Mix polyol, water, tin dioctoate, triethylenediamine and diethylamine oleate in a mass ratio of 100: 6: 1: 0.5: 4 to obtain 7.3g of chain extender, the polyhydroxy The compound contains 0.73g polycaprolactone, 3.47g ethylene glycol, 2.0g 1,2-propanediol, 1.1g trimethylolpropane with a molecular weight of 500g / mol;

[0039]Quickly add the chain extender to the prepolymer, set the stirring speed to 1000rpm, and the stirring time to 30s to obtain a mixed material, quickly inject the prepared mixed material into a 110°C vul...

Embodiment 2

[0041] Place 100 g of polycaprolactone with a number average molecular weight of 3000 in a 1L three-necked bottle, set the temperature at 120°C, remove the water in the polycaprolactone polyol in a vacuum environment, and lower the temperature to 80°C, Under the protection of a nitrogen atmosphere, 10.67 g of p-phenylene diisocyanate was added to a three-necked flask, stirred at a speed of 1000 rpm for 2.5 hours, and the prepared prepolymer-NCO% content was calibrated to 2.5%;

[0042] Polyol, water, tin laurate, pentamethyldiethylenetriamine and dimethyl polysiloxane are mixed in a mass ratio of 100: 8: 1.2: 0.6: 6 to obtain 3.2 g of chain extenders, 0.48g polycaprolactone, 0.96g 1,4-butanediol, 0.64g 1,3-propylene glycol, 1.12g sorbitol with a molecular weight of 1000g / mol are included in the polyhydroxy compound;

[0043] Quickly add the chain extender to the prepolymer, set the stirring speed to 1700rpm, and the stirring time to 10s to obtain a mixed material, quickly inje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com