Buffer oil cylinder for plastic product forming machinery

A technology of plastic products and cushioning cylinders, which is applied in the field of cushioning cylinders, and can solve problems such as poor applicability, difficulty in exerting the cushioning effect of the plunger, and large molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

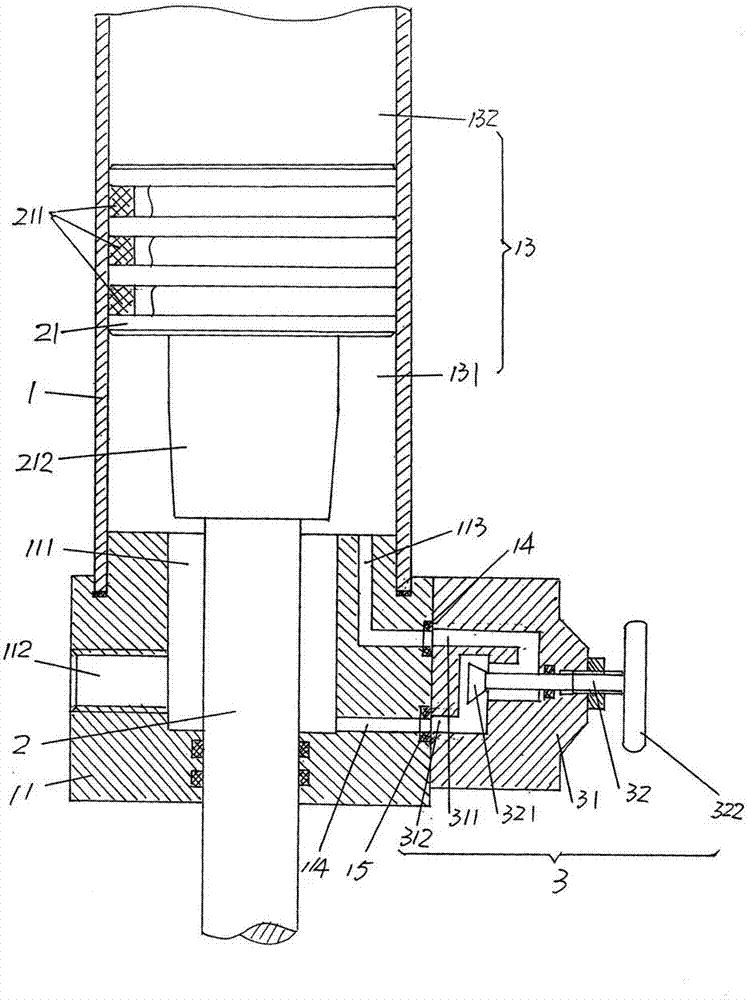

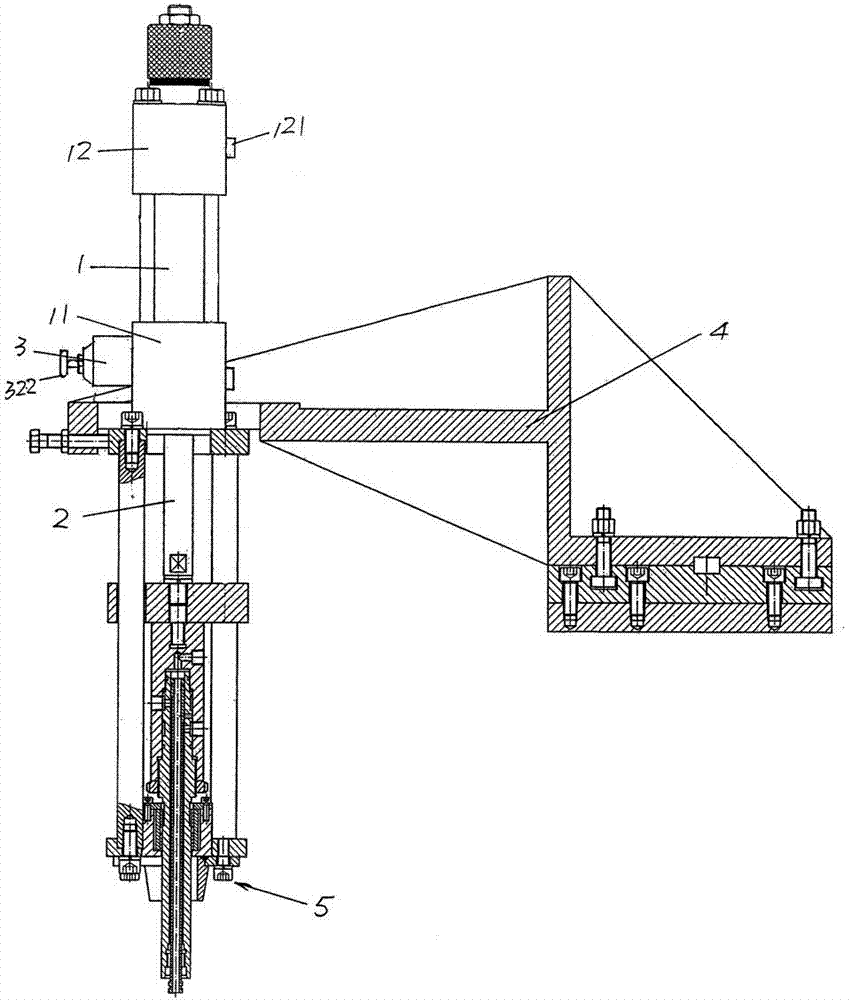

[0019] Please see figure 1 with figure 2 , given the cylinder head 11 and tailstock 12 ( figure 2 Shown) the oil cylinder body 1, the oil cylinder body 1 is fixed between the oil cylinder head 11 and the tailstock 12 by a set of fixing rods. The cylinder chamber of the oil cylinder block 1 is formed as an oil chamber 13, and the oil cylinder column 2 that moves up and down (taking the position shown in the figure as an example) is arranged in the oil chamber 13 .

[0020] The aforementioned cylinder head 11 forms a cylinder head buffer oil chamber 111, and an oil cylinder head inlet and outlet hole 112 is opened on the side of the cylinder head 11, and the oil cylinder head inlet and outlet hole 112 is provided with an oil inlet and outlet joint (not shown in the figure) , the oil inlet and outlet joints are connected to the oil pump or similar hydraulic oil devices through pipelines. An oil cylinder column piston head 21 with a diameter larger than that of the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com