Automobile transmission reverse gear anti-wrong device

An automotive transmission, error-proofing technology, applied in transmission control, components with teeth, belts/chains/gears, etc., can solve the problems of transmission gearbox impact, transmission parts damage, reverse gear safety mechanism failure, etc. Achieve the effects of easy manufacturing and processing, low assembly requirements, and avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

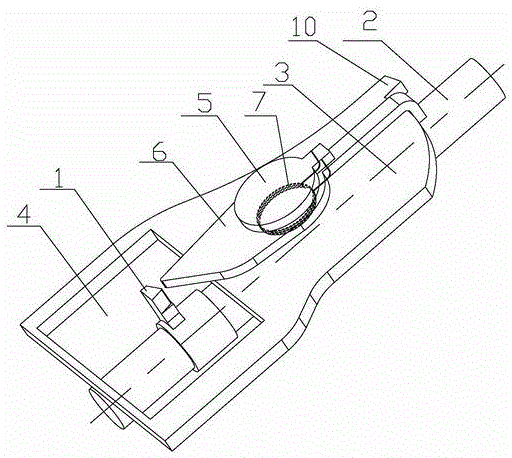

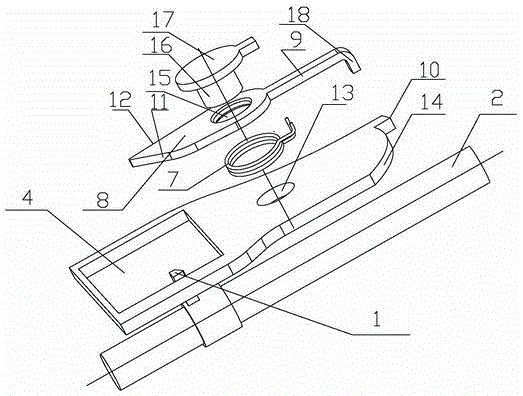

[0018] The reverse gear anti-error device of the automobile transmission of the present invention is arranged in cooperation with the shift shaft 2 with the shift paddle 1. In terms of design idea, the whole device is fixed on the transmission housing to avoid the shifting of the shift shaft. The structural complexity brought about by the above setting and the failure phenomenon of use loss occur. In terms of specific structural design ideas, the device includes a fixed plate 3 fixedly connected to the transmission case, and an anti-error limit device positioned on the fixed plate 3. The shift block 1 is extended from the through hole 4 on the fixed plate 3. and when the fifth gear and reverse gear are selected, it cooperates with the anti-mistake limiting device. Provide the shift paddle 1 with a limiting force that limits the above actions.

[0019] In the specific structural design, the figure 1 , figure 2 One of the implementations shown based on the above design idea ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com