Ceramic household appliance and manufacture method thereof

A technology for a household appliance and a manufacturing method, which is applied to household refrigeration devices, household stoves, household heating and other directions, can solve problems such as inability to use household appliances for large-area decoration, poor corrosion resistance, shortened hinge life, etc., and achieve artistic effects. Intense, rich in layer changes, and the effect of enhancing the thermal insulation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

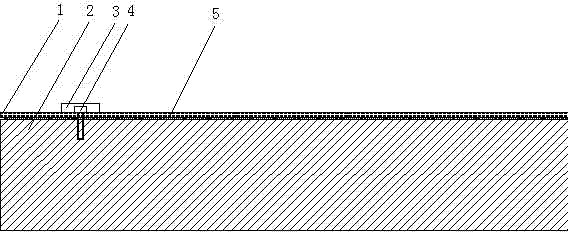

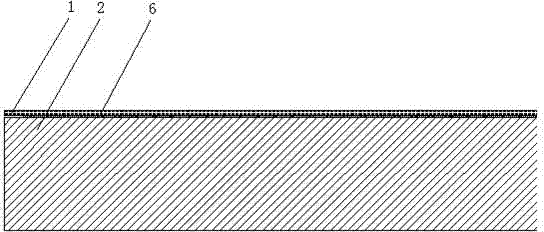

[0031] An embodiment of a ceramic household appliance according to the present invention includes a housing and a panel, and the housing or / and the panel are provided on the surface of a thin ceramic plate.

[0032] The ceramic thin plate is a plate-shaped ceramic product made of clay and other inorganic non-metallic materials through high-pressure molding and high-temperature calcination at 1200 degrees. It not only upholds the advantages of inorganic materials, but also abandons the disadvantages of traditional inorganic materials such as stone, metal plates, and glass plates, which are heavy and high in carbon. It can meet the requirements of A1 class fire protection.

[0033] Lifespan: After high-temperature calcination, the color tone of the screen can last for more than 100 years in the room without fading; it is convenient to stick, screw and other methods.

[0034] Thickness 2-5mm, water absorption 35.

[0035] It has the advantages of resistance to strong acid, stro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com