Flexible flat heat pipe

A flat heat pipe, flexible technology, applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of irregular heat dissipation surface, low thermal conductivity of heat pipe, poor sealing, etc., to achieve light and easy to manufacture, High thermal conductivity, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

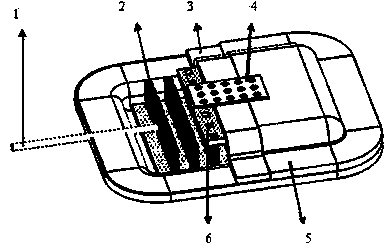

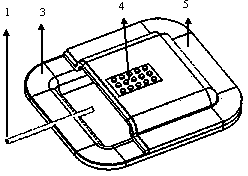

[0011] figure 1 , the working fluid enters the capillary structure through the liquid-filled tube 1.

[0012] The working medium used is water.

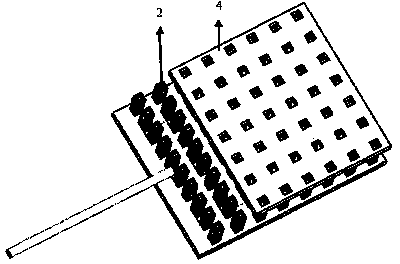

[0013] The entire sintered interior is covered with a layer of silicon rubber cover 5, and the cover is bonded through silicon rubber.

[0014] The casing 3 is composed of upper and lower parts, and the edge adopts a curling sealing structure, which is more conducive to the overall sealing of the heat pipe.

[0015] In the center of the upper and lower surfaces of the silicone rubber cover, there are areas accounting for about 30% of the surface area of the entire cover. Copper is electroplated in these areas, and the electroplated copper is in contact with the shell, which is beneficial to the heat conduction of the flat heat pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com