Method for manufacturing broad-spectrum strong-focusing Fresnel lens

A technology of a Fresnel lens and a manufacturing method, applied in the optical field, can solve the problems of poor concentrating sunlight effect, difficulty in obtaining high conversion efficiency, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

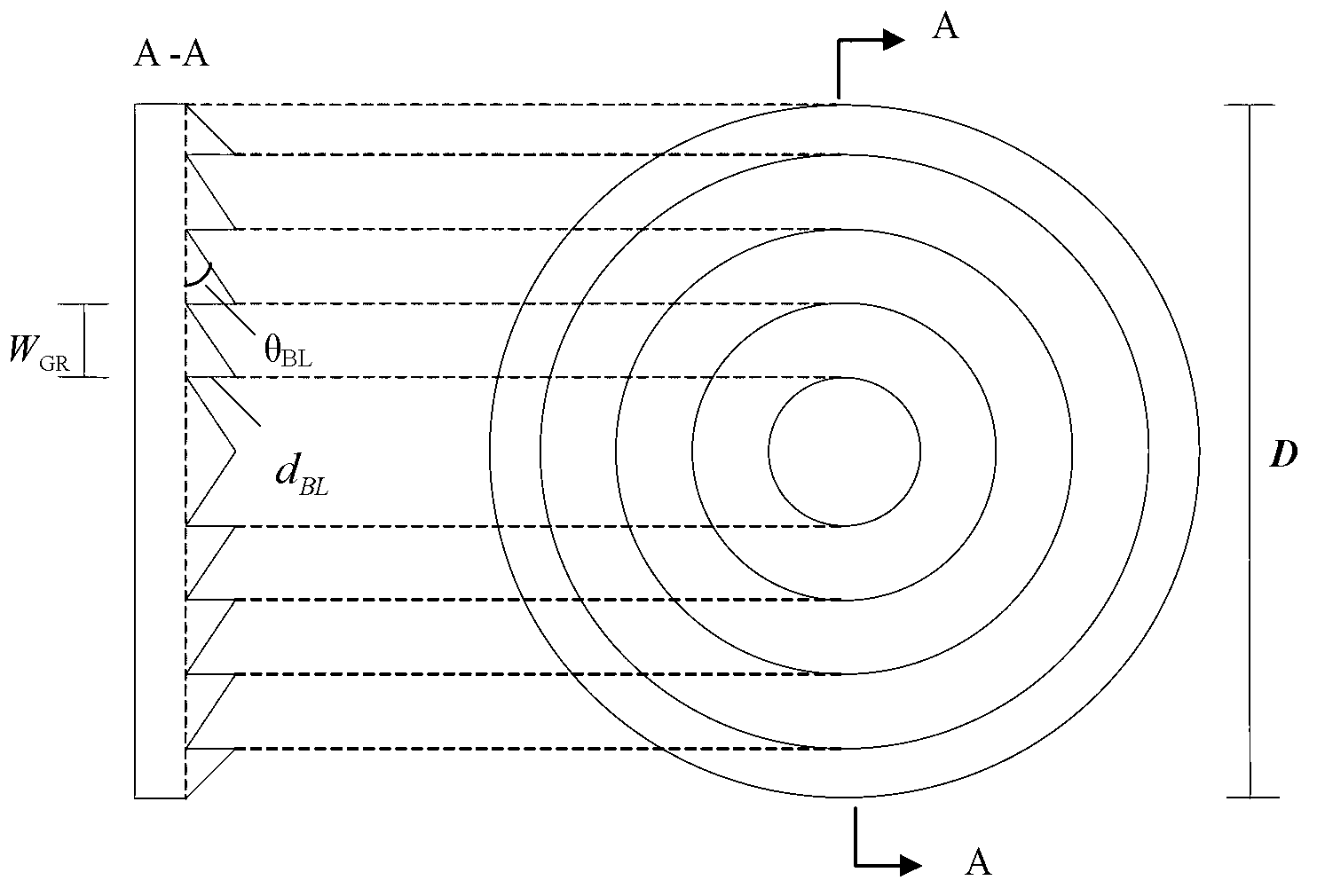

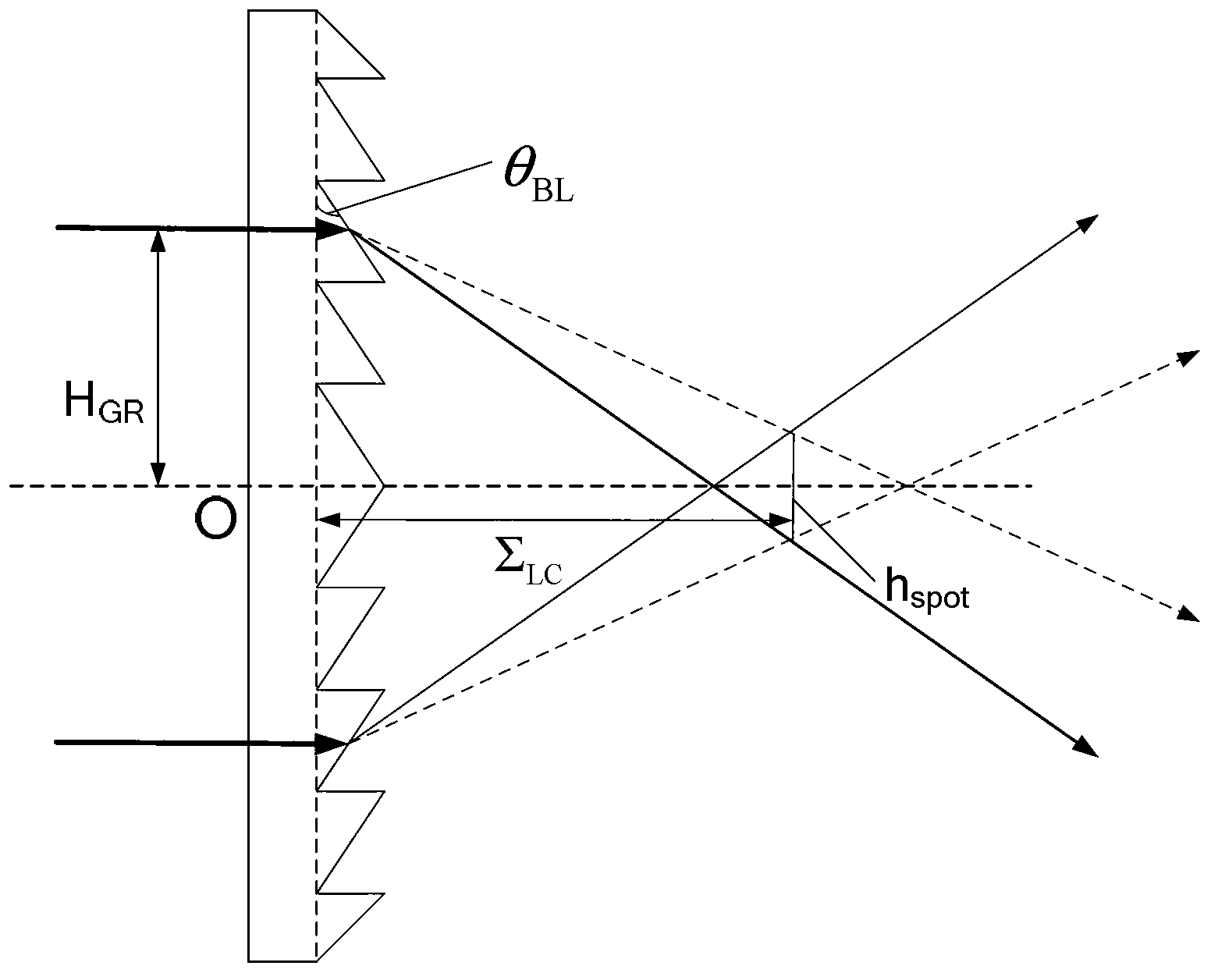

[0032] Specific implementation mode one: the following combination Figure 1 to Figure 3 Describe this embodiment mode, the manufacturing method of a kind of wide-spectrum strong focusing Fresnel lens described in this embodiment mode, the realization process of this method is:

[0033] Step 1, setting the iterative relationship between the inclination angle of the ring of the Fresnel lens to be made and the distance of the ring from the center of the lens circle is:

[0034] H GR = H GR - 1 + d BL / 2 tan ( θ BL ) + d BL / ...

specific Embodiment approach 2

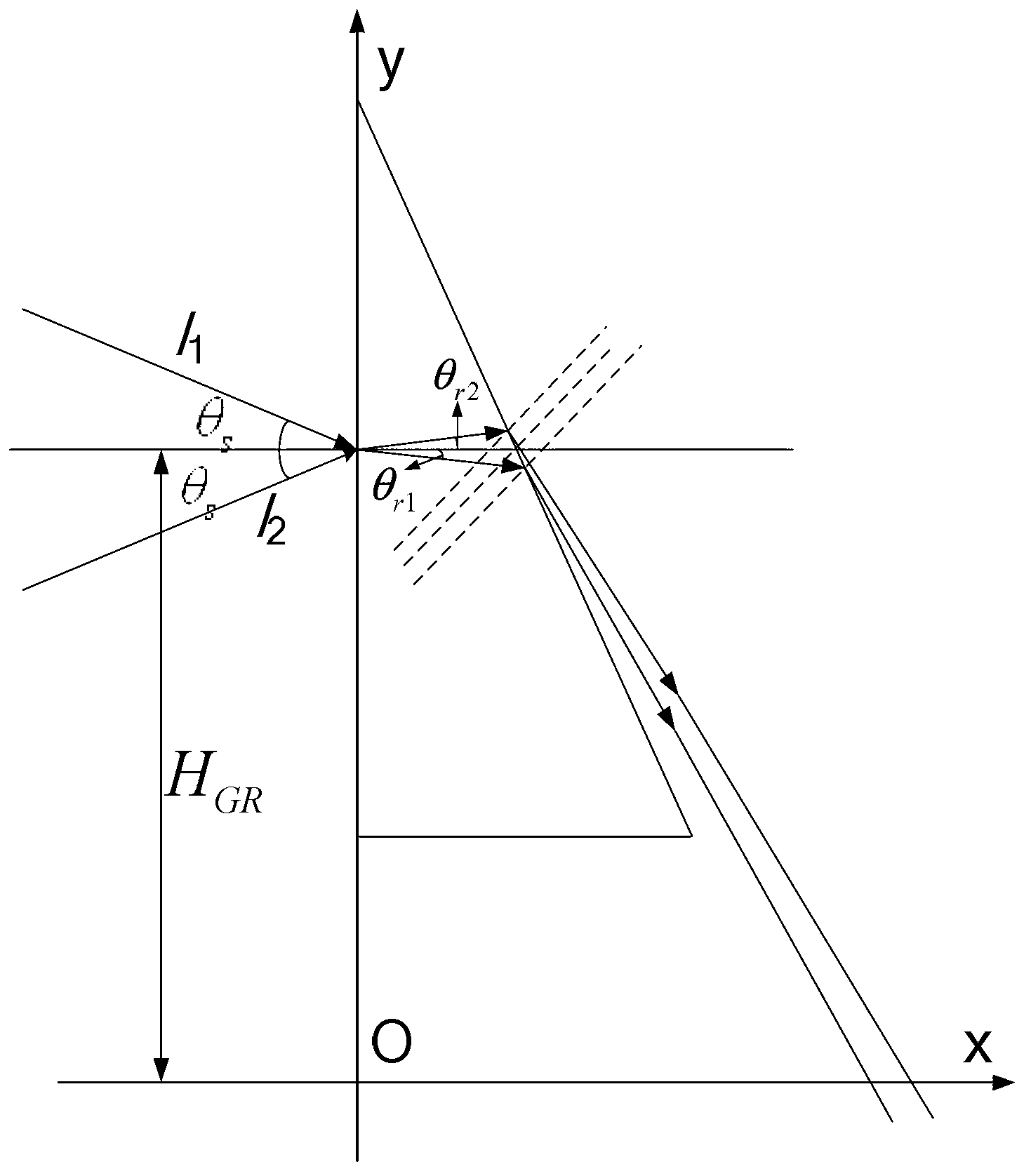

[0050] Specific implementation mode two: the following combination Figure 1 to Figure 3 Describe this embodiment, this embodiment is to obtain θ for Embodiment 1 BL with H GR Further description of the iterative relational formula of the present embodiment, step 3 described in this embodiment, uses the estimation and correction algorithm to solve formula (3) and formula (5) iteratively to obtain θ BL with H GR The method is: according to W GR 、H GR with theta BL Direct relationship:

[0051] tan ( sin - 1 [ n R sin θ BL ] - θ BL ) = 2 H GR Σ LC ...

specific Embodiment approach 3

[0054] Specific implementation mode three: the following combination Figure 1 to Figure 3 Describe this embodiment. This embodiment is a further description of the estimation and correction algorithm used in Embodiments 1 and 2. The estimation and correction algorithm described in this embodiment is used to solve formula (3) and formula (5). The inclination angle θ of each ring BL with ring height H GR The predictive and corrective formulas of the predictive correction algorithm are:

[0055] y n + 1 * = y n - q + h Σ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com