Novel floater type liquid level automatic control device

A liquid level automatic control, float type technology, applied in liquid level control, non-electric variable control, control/regulation system and other directions, can solve the problems of unstable force transmission, easy falling off, force transmission failure of gears, etc., and achieve extended use. Long life, good control effect and good force transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail:

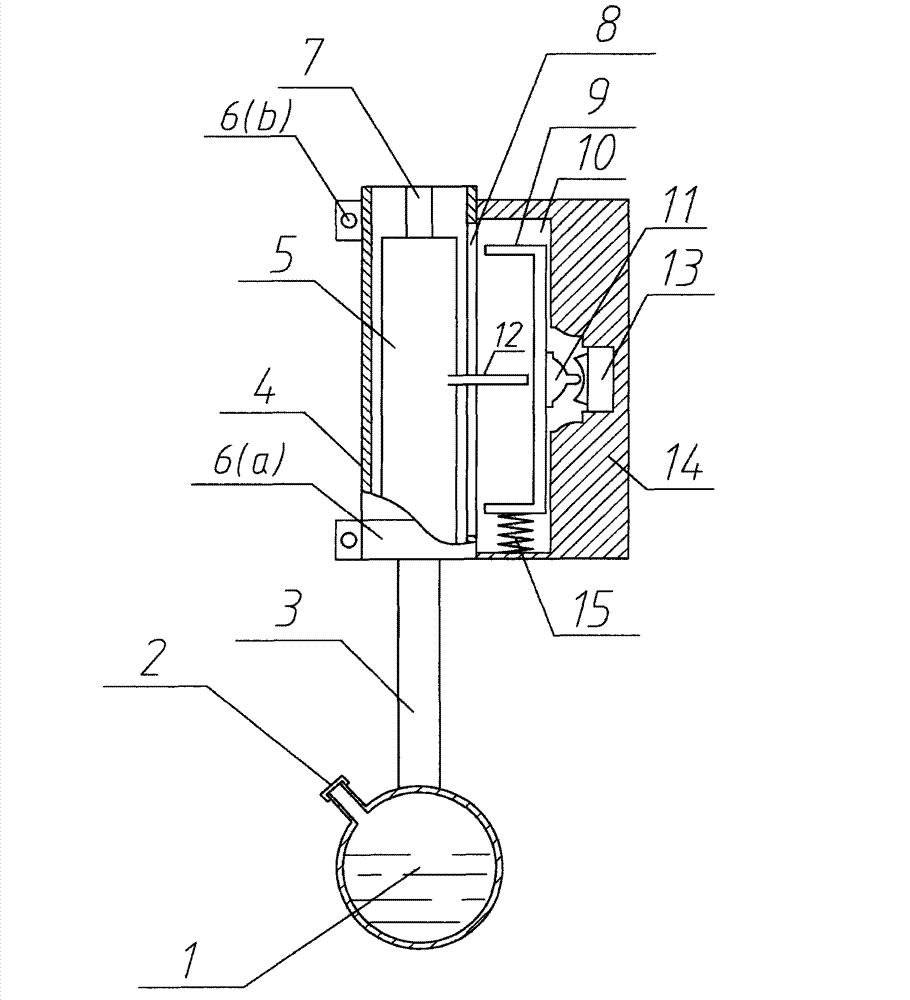

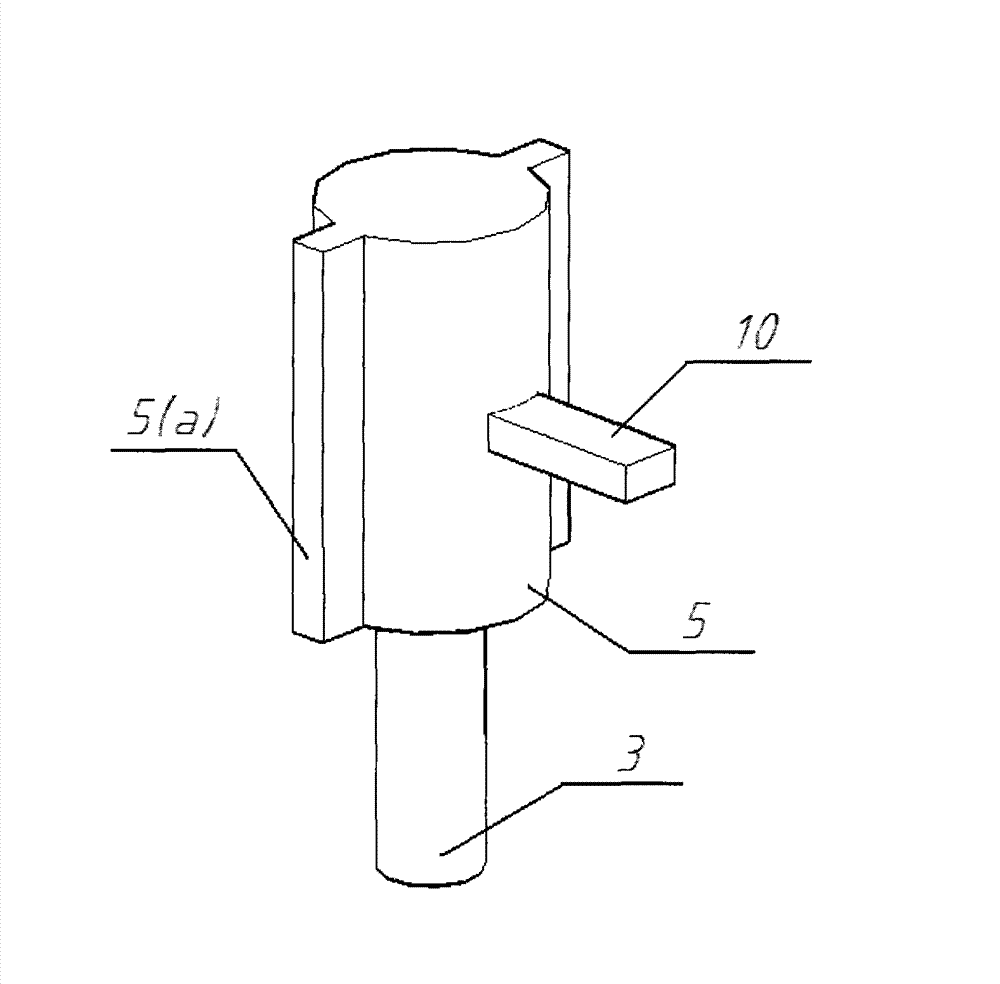

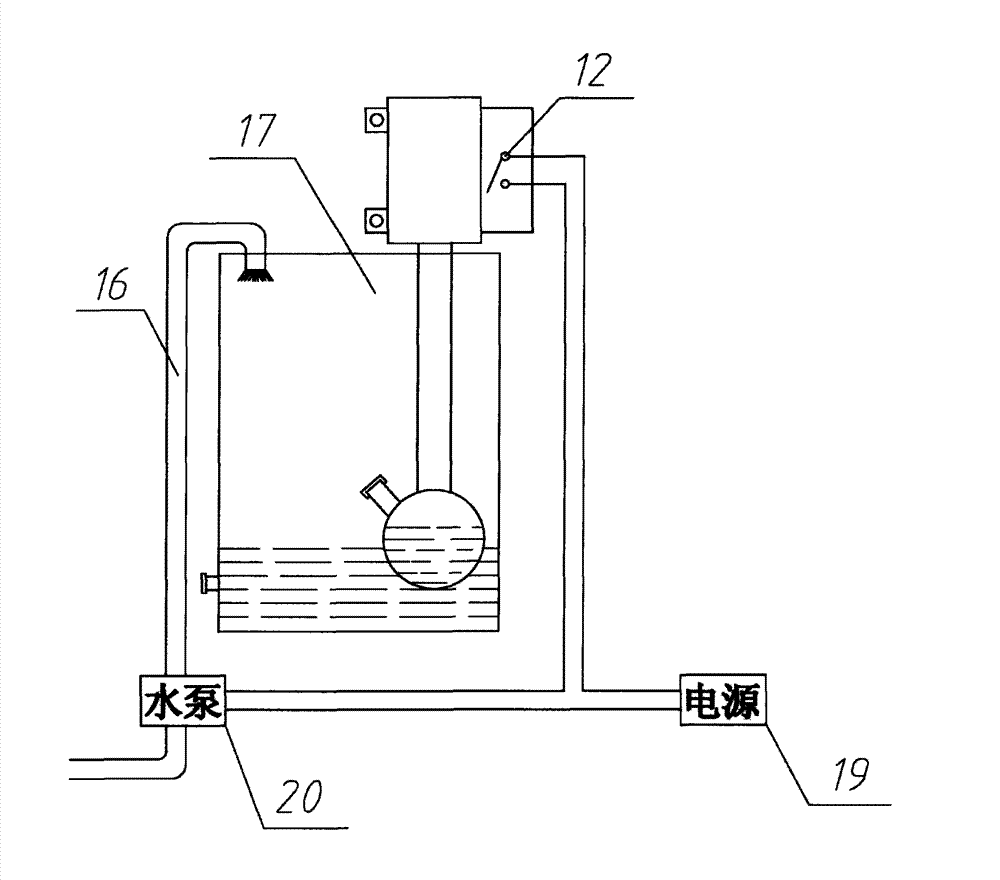

[0019] see figure 1 , 2 , 3, a new float type liquid level automatic control device, including float 1,, slide 4, slide rod 5, toggle lever 9, toggle lever cavity 10, power switch 13 and some auxiliary devices. It is characterized in that one end of the long arm 3 is connected with a float 1, and one end is connected with a slide bar 5; the slide bar 5 is provided with a slide bar 5 (a); ) corresponding to the slideway 7, so that the slide bar 5 can slide vertically in the slide tube 4; the slide bar 5 is provided with a lever 12 for toggling the toggle lever 9; the toggle lever 9 is provided with a vertical shift block 11 is used for toggling power switch 13; This power switch 13 is connected with the electric device that feeds water tank 17 water supply.

[0020] see figure 1 One side of the slider 4 of the present invention is provided with a lever slide hole 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com