Method of attaching a metal surface to a carrier

A metal surface and carrier technology, which is applied in the manufacture of electrical solid state devices, semiconductor devices, semiconductor/solid state devices, etc., can solve the problems of chip connection and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

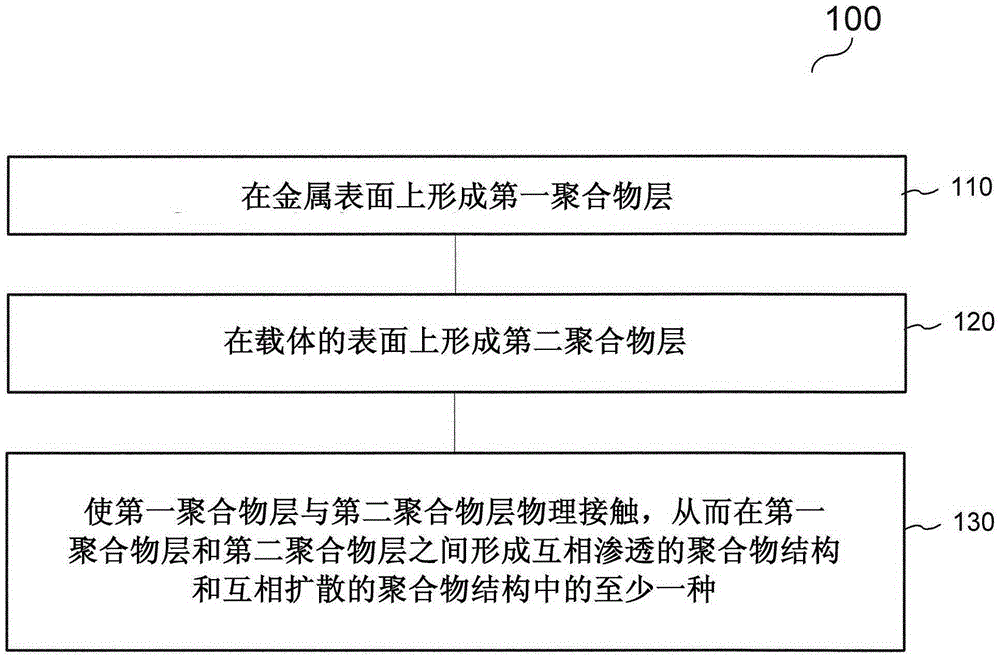

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0081] According to an embodiment, the carrier comprises a printed circuit board.

[0082] According to an embodiment, the carrier comprises a further chip.

[0083] According to an embodiment, the carrier comprises a semiconductor wafer.

[0084] According to an embodiment, the carrier includes a lead frame.

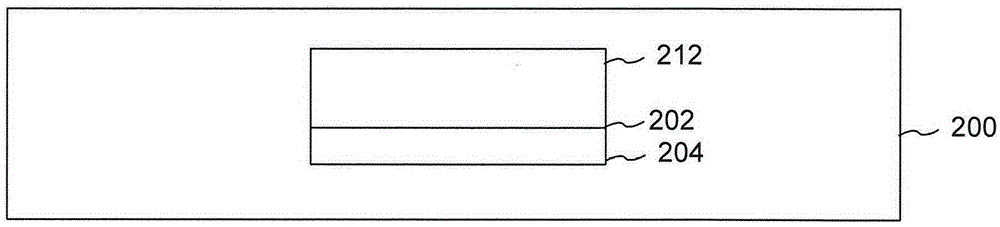

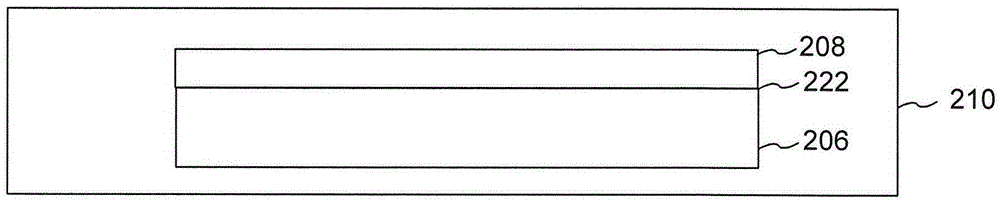

[0085] A chip packaging module is disclosed. The chip packaging module includes: a chip and a chip carrier; a first polymer layer formed on the surface of the chip; a second polymer layer formed on the surface of the chip carrier; at least one of an interpenetrating polymer structure and an interdiffused polymer structure formed between the layer and the second polymer layer;

[0086] According to an embodiment, the first polymer layer on the surface of the chip has a thickness ranging from about 100 nm to about 5 μm.

[0087] According to an embodiment, the second polymer layer on the surface of the chip carrier has a thickness ranging from about 100 nm to about 5 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com