Automatic assembling machine for micro motor rotor

An automatic assembly machine and micro-motor technology, applied in the manufacture of stator/rotor bodies, etc., can solve the problems of standardization, mechanization, large-scale production, unstable product quality, and low product qualification rate of micro-motors, and meet the requirements of large-scale Large-scale standardized production, high assembly efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is the best example of the micro motor rotor automatic assembly machine of the present invention, which does not limit the protection scope of the present invention.

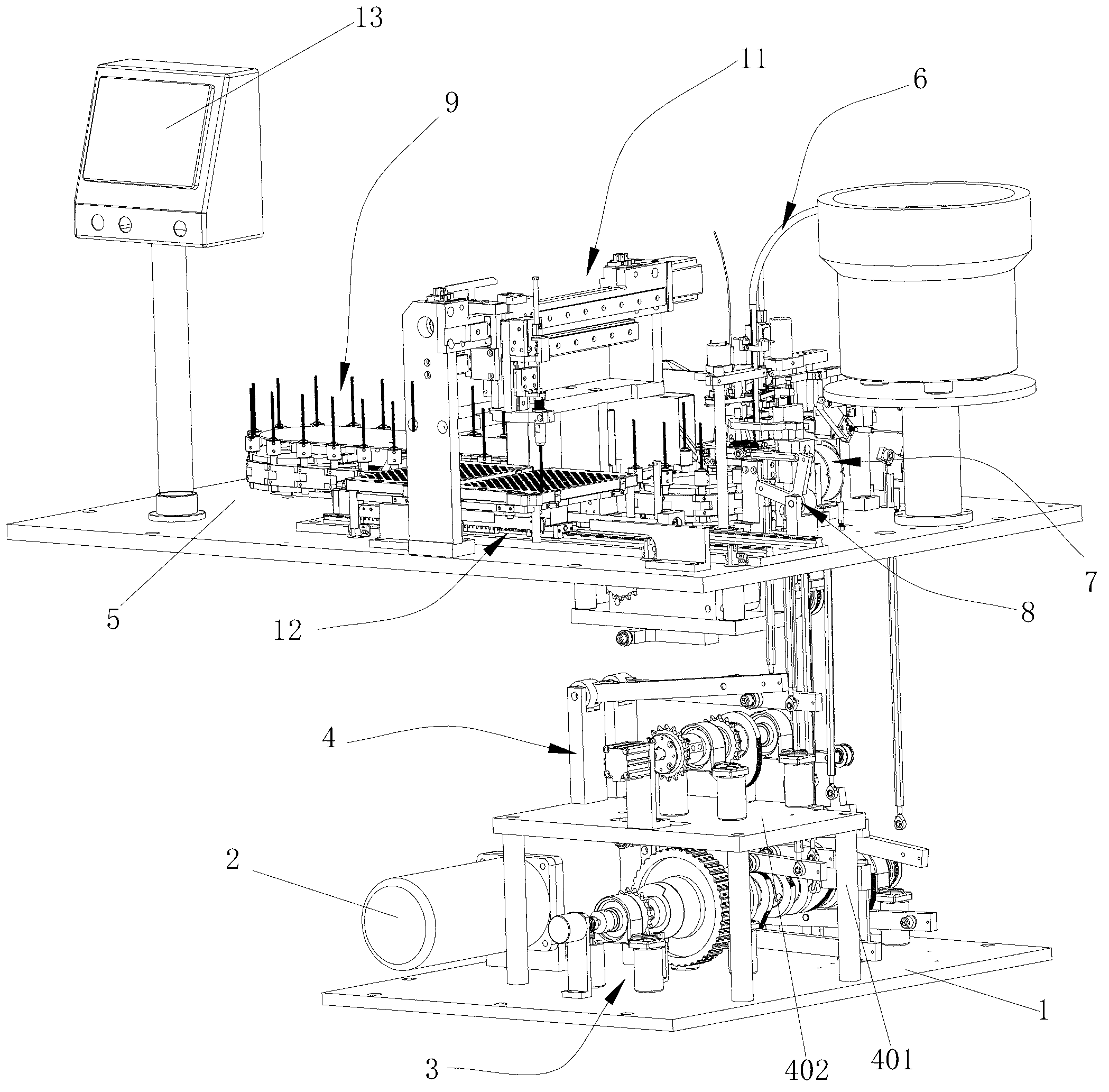

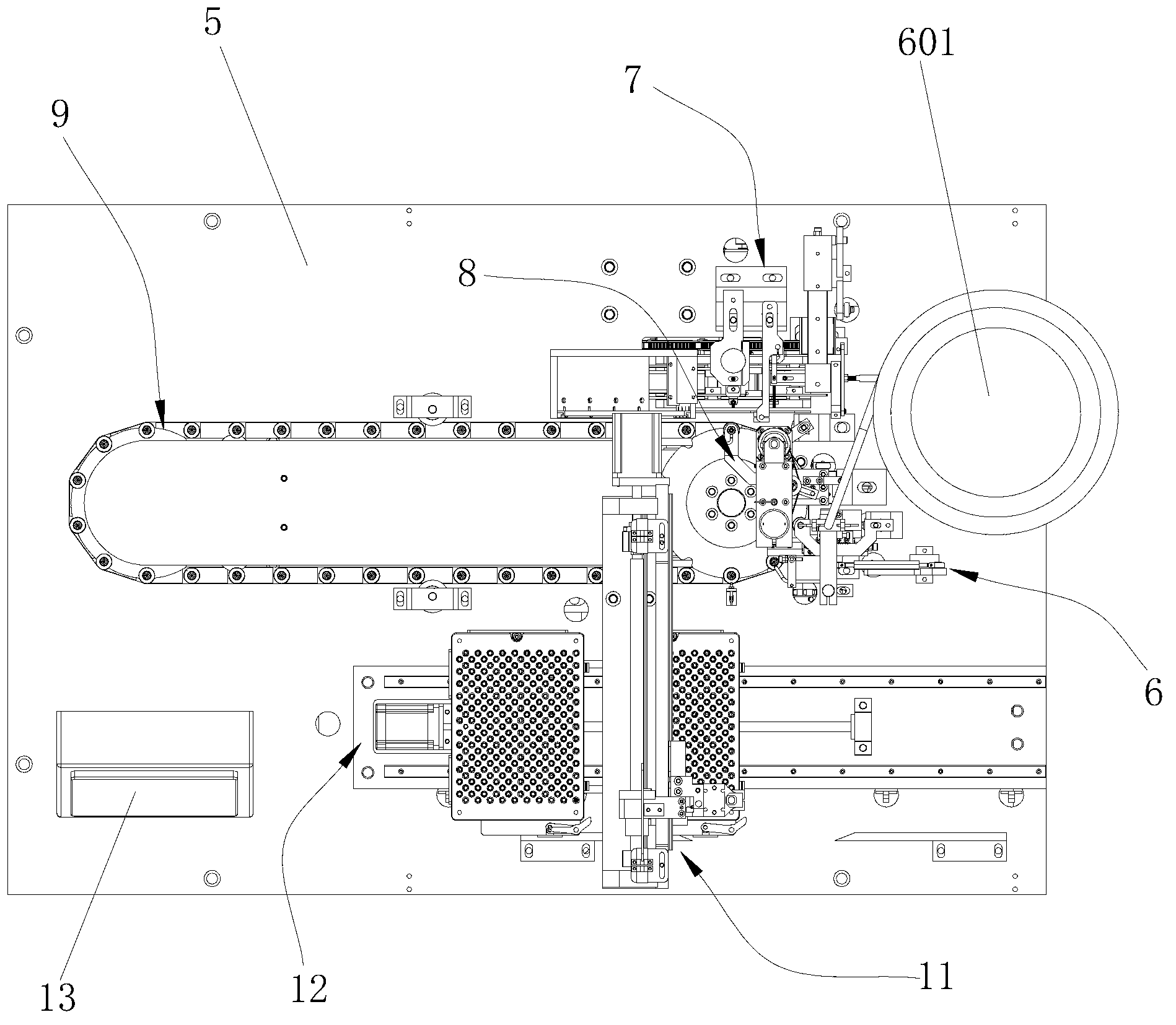

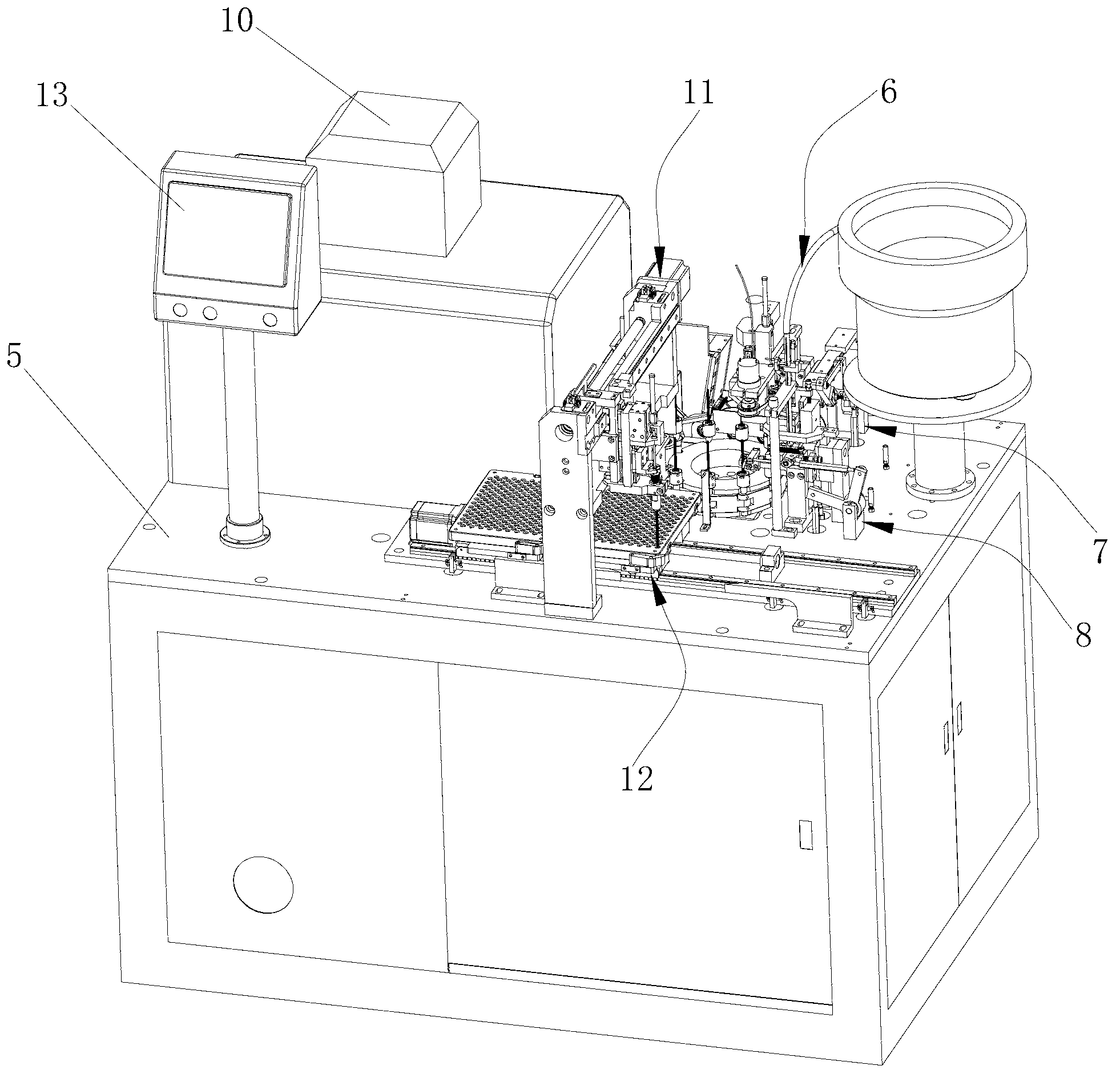

[0028] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , providing a micro motor rotor automatic assembly machine, including a first base plate 1, a workbench 5 installed above the first base plate 1, and a driving motor 2, a main transmission mechanism 3, a secondary Transmission mechanism 4, the driving motor 2 is connected with the main transmission mechanism 3, the auxiliary transmission mechanism 4 is installed above the main transmission mechanism 3, the workbench 5 is equipped with a magnetic ring assembly mechanism 6, and the rotor shaft is dispensing and rotating The displacement mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com