Linkage energy-saving control device for common bus servo controller

A servo controller, energy-saving control technology, applied in the field of servo control, can solve the problems of unreasonable use of electric energy, leakage, waste of energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

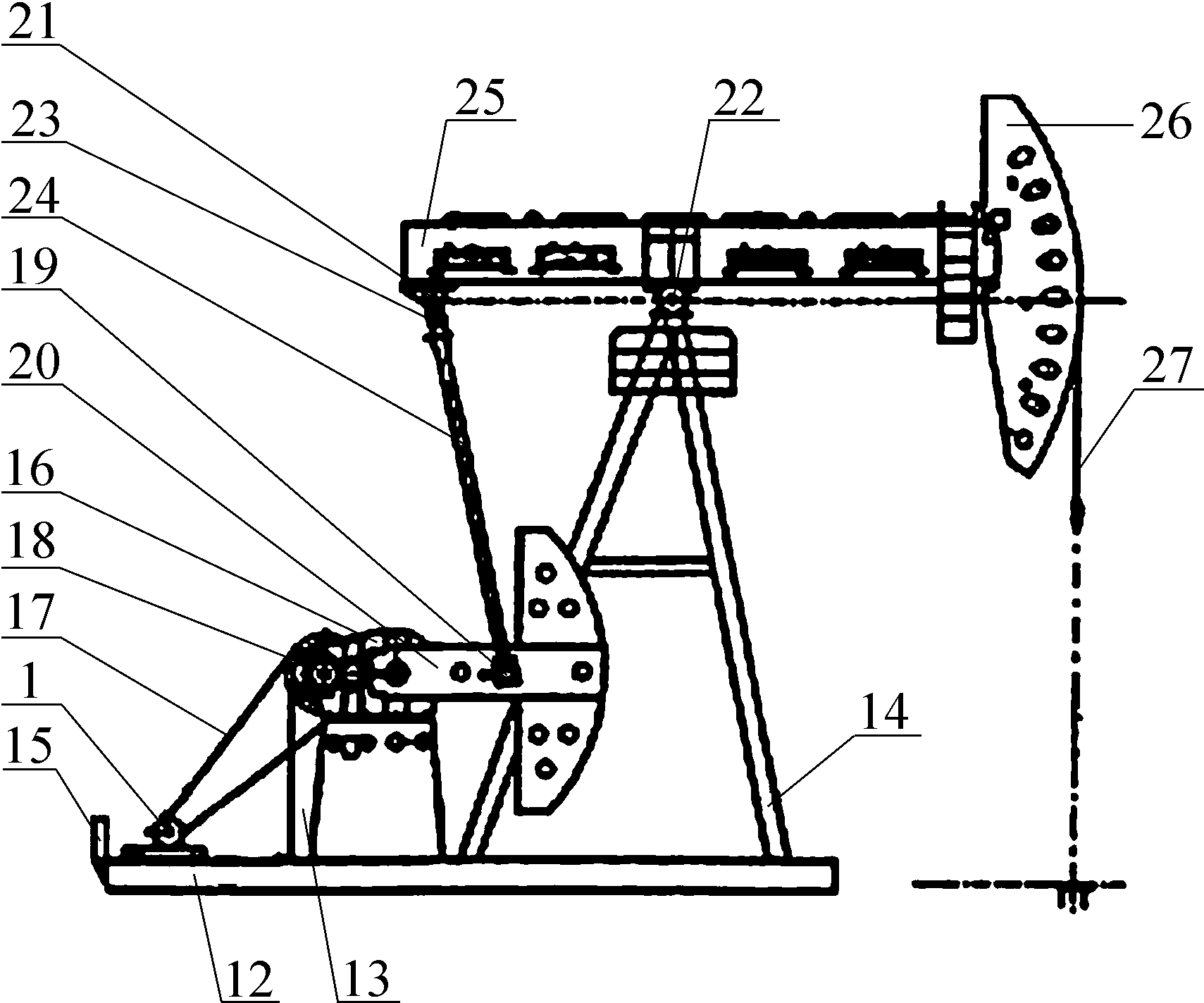

[0015] Take an oil field as an example: There are multiple pumping units at the same location in the oil field. The pumping units are beam-type, including AC servo motor 1, base 12, fixed frame 13, bracket 14, power distribution box 15, and reducer 16. , Belt 17, brake device 18, crank pin 19, crank 20, beam 21, pin shaft 22, bearing 23, connecting rod 24, walking beam 25, donkey head 26 and suspension rope 27, such as figure 1 As shown, the specific structure is: an AC servo motor 1, a fixing frame 13 and a bracket 14 are sequentially fixed on the base 12, and the AC servo motor 1 is controlled by a servo controller in a power distribution box 15 on one side of the base 12, and a reducer 16 is fixed on the fixed frame 13, the rotating shaft of the AC servo motor 1 is connected to the input shaft of the reducer 16 through a belt 17, a brake device 18 is provided on the reducer 16, and the output shaft of the reducer 16 is connected through a crank pin 19 and a crank 20 , The mid...

Embodiment 2

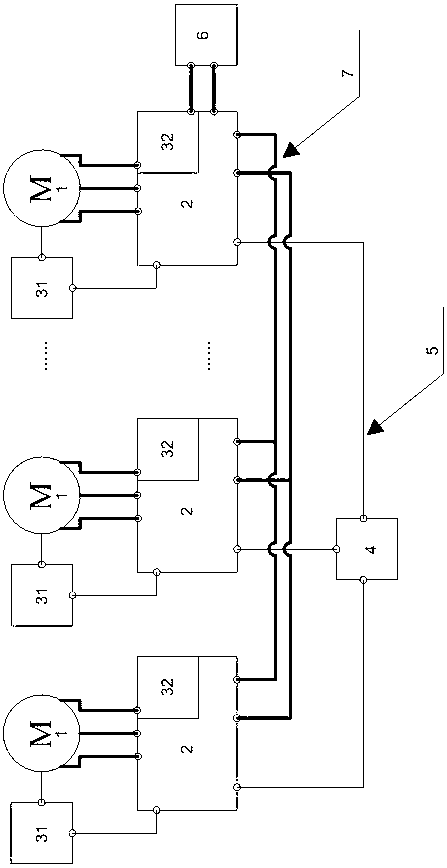

[0020] A linkage energy-saving control device for a common bus servo controller, including an AC servo motor 1, a servo controller 2, a speed sensor 31, a voltage sensor 32, a master controller 4 and a braking resistor 6, such as image 3 As shown, the specific structure is: the topological relationship of each servo controller 2 communication line 5 connection selects a bus connection, each servo controller 2 is connected through the communication line 5, and then connected to the master controller 4 through the communication line 5. The communication method can be adopted For CAN communication, RS485 communication or Ethernet communication, CAN communication is selected in this embodiment, and the main controller 4 is a microcomputer. Other structures and methods of use are the same as in Example 1.

Embodiment 3

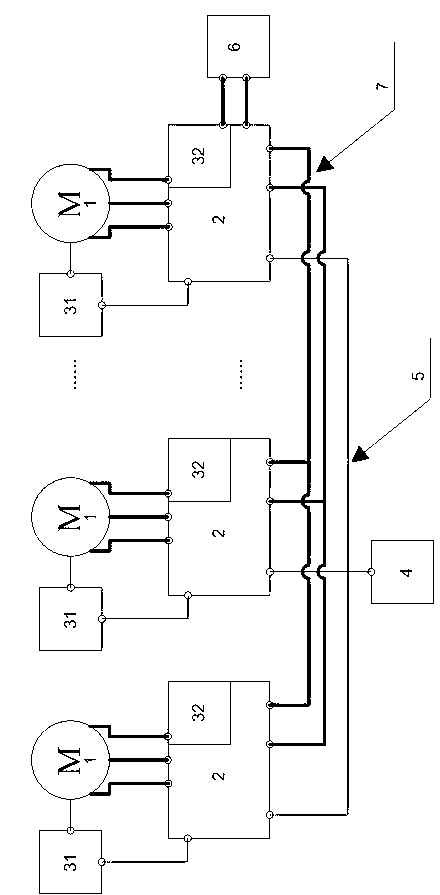

[0022] A linkage energy-saving control device for a common bus servo controller, including an AC servo motor 1, a servo controller 2, a speed sensor 31, a voltage sensor 32, a master controller 4 and a braking resistor 6, such as Figure 4 As shown, the specific structure is: the topological relationship of each servo controller 2 communication line 5 connection selects a ring connection, each servo controller 2 is connected end to end through the communication line 5 in turn, and the master controller 4 is connected to one of the servo controllers. 2; The total controller 4 uses a microcomputer. Other structures and methods of use are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com