Heat treating apparatus

A technology of heat treatment device and treatment chamber, which is applied in coating, gaseous chemical plating, metal material coating process, etc., can solve the problem of wafer temperature uniformity deterioration, wafer temperature uniformity deterioration, temperature uniformity damage, etc. problems, to achieve the effect of improving heating efficiency and accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. In addition, in this specification and drawings, the same code|symbol is attached|subjected to the structural unit which has substantially the same functional structure, and repeated description is abbreviate|omitted.

[0060] (Example of configuration of heat treatment equipment)

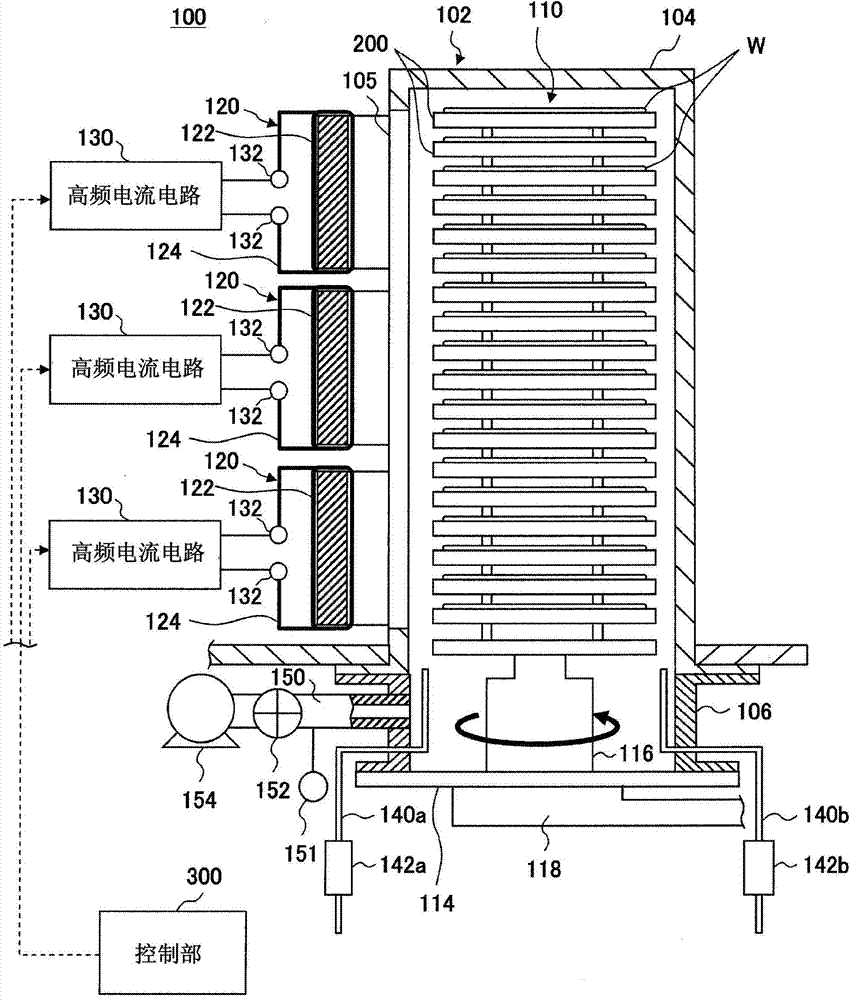

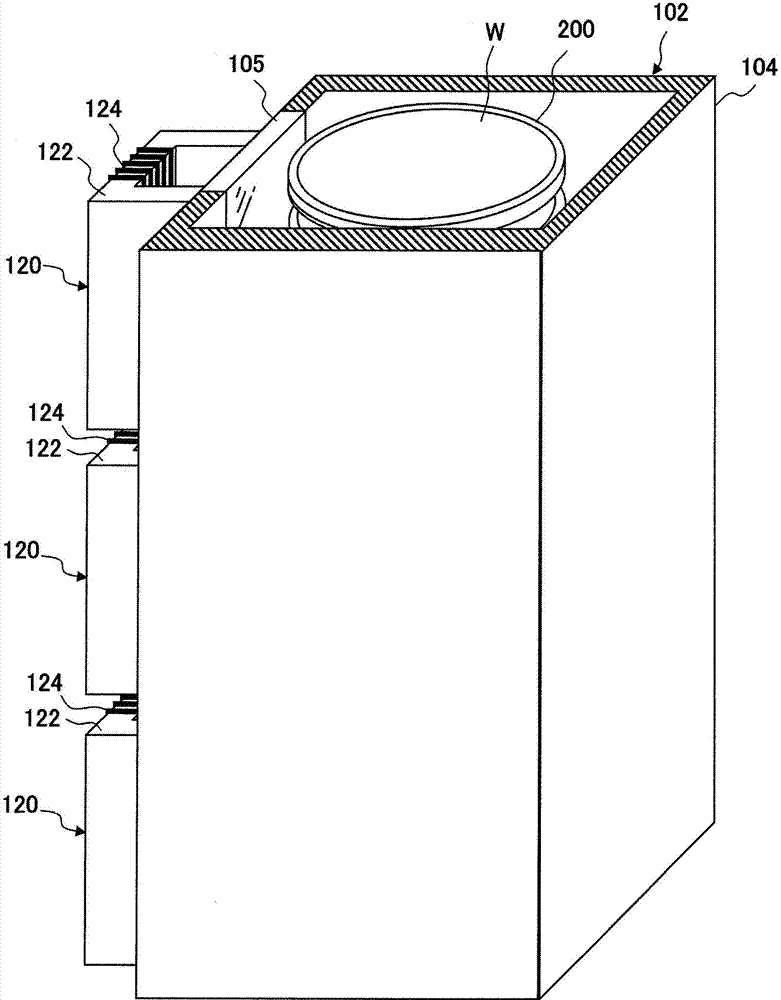

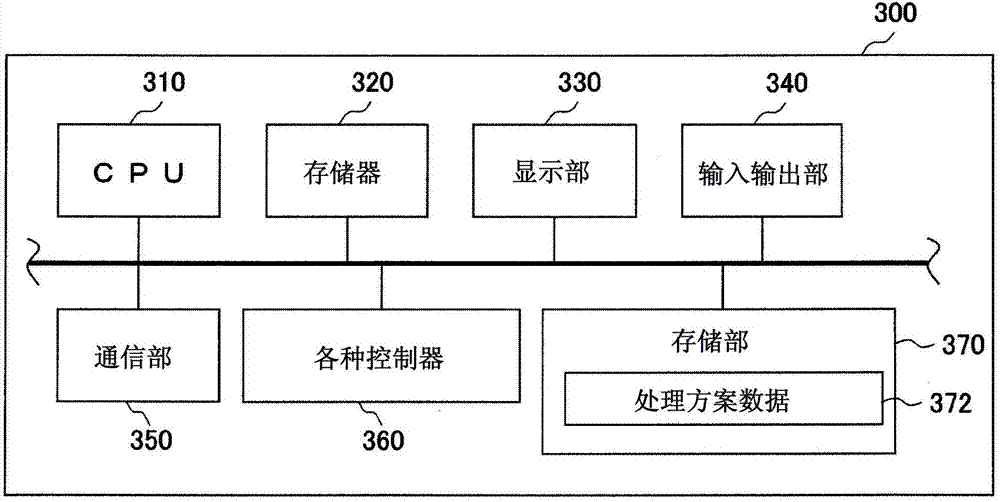

[0061] First, a heat treatment apparatus according to an embodiment of the present invention will be described. Here, with reference to the accompanying drawings, a batch-type vertical heat treatment device (hereinafter referred to simply as a "heat treatment device") capable of heat-treating multiple pieces of a semiconductor wafer (hereinafter referred to as a "wafer") as a substrate to be processed will be described. ) as an example to illustrate. figure 1 is a cross-sectional view showing a configuration example of a heat treatment apparatus, figure 2 It is a perspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com