Pcb with cavity and fabricating method thereof

A manufacturing method and cavity technology, which are applied in multilayer circuit manufacturing, printed circuit manufacturing, and mechanically removing conductive materials, etc., can solve the problems of narrowing the cavity design range and achieve the effect of precise control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

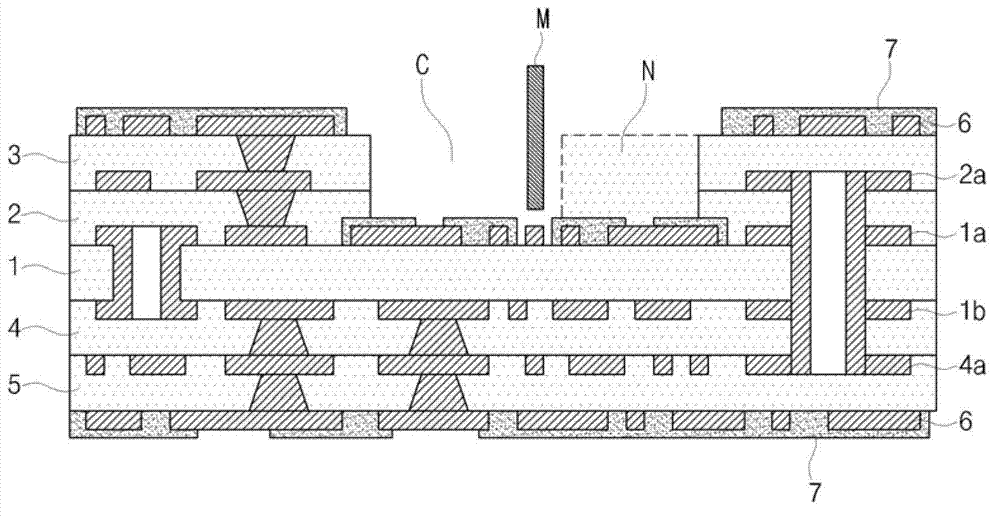

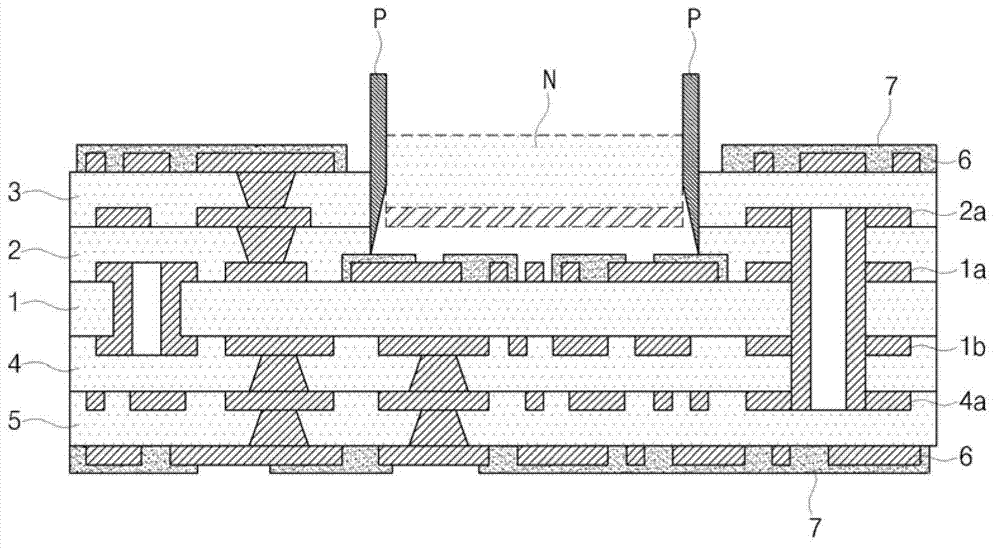

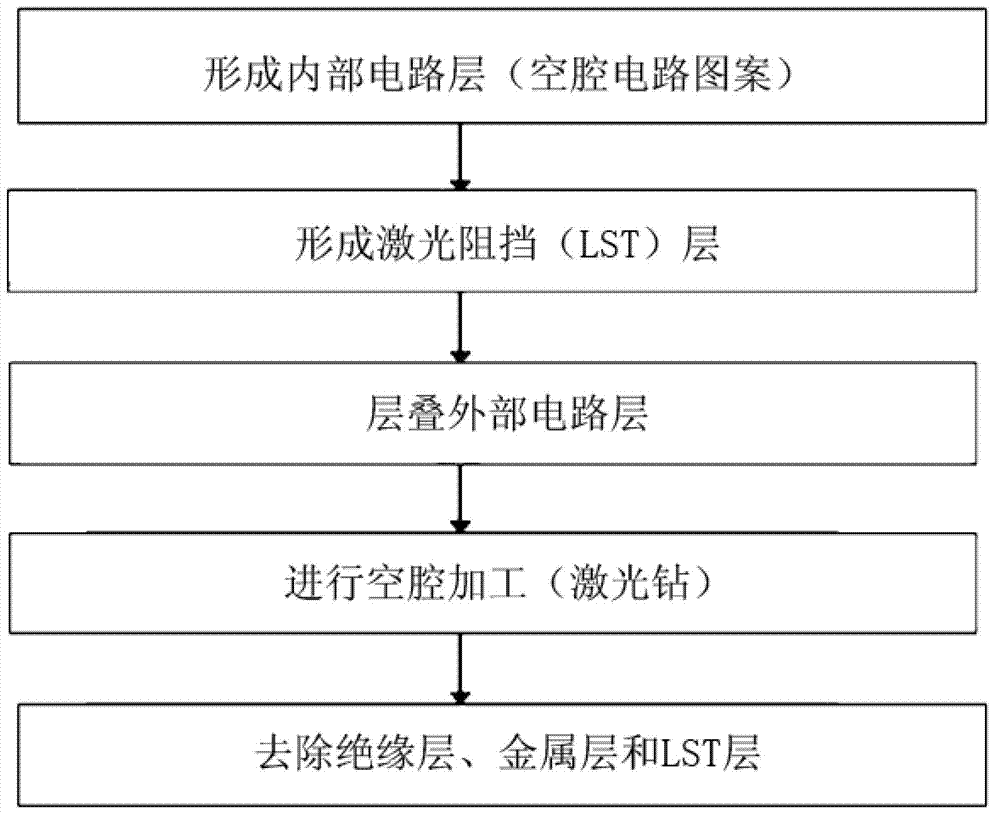

[0023] The present invention provides a method of manufacturing a printed circuit board with a cavity, in which a multilayer PCB is formed by a laser barrier, and then a cavity area is processed, whereby the processing freedom of the cavity can be improved and the circuit in the cavity can be protected .

[0024] For this, a basic circuit board is formed on the surface of the substrate, the basic circuit board is provided with an inner circuit layer including a cavity circuit pattern, and a laser blocking layer is partially formed on the cavity circuit pattern. Then, at least one outer circuit layer is formed on the basic circuit board, and a cavity region is formed on the upper portion of the laser blocking layer by removing the outer circuit layer.

[0025] Reference will now be made in detail to the exemplary embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein like numerals refer to like elements throughout. Exempla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com