Wild jujube kernel removing machine

A jujube jujube and frame technology, which is applied in fruit pitting devices, solid separation, and separation of solids from solids with airflow, etc., can solve unfavorable jujube meat recovery and utilization, large pitch of rotor webs, environmental pollution, etc. problems, to achieve the effect of facilitating classified collection and processing, improving crushing efficiency, and optimizing crushing functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

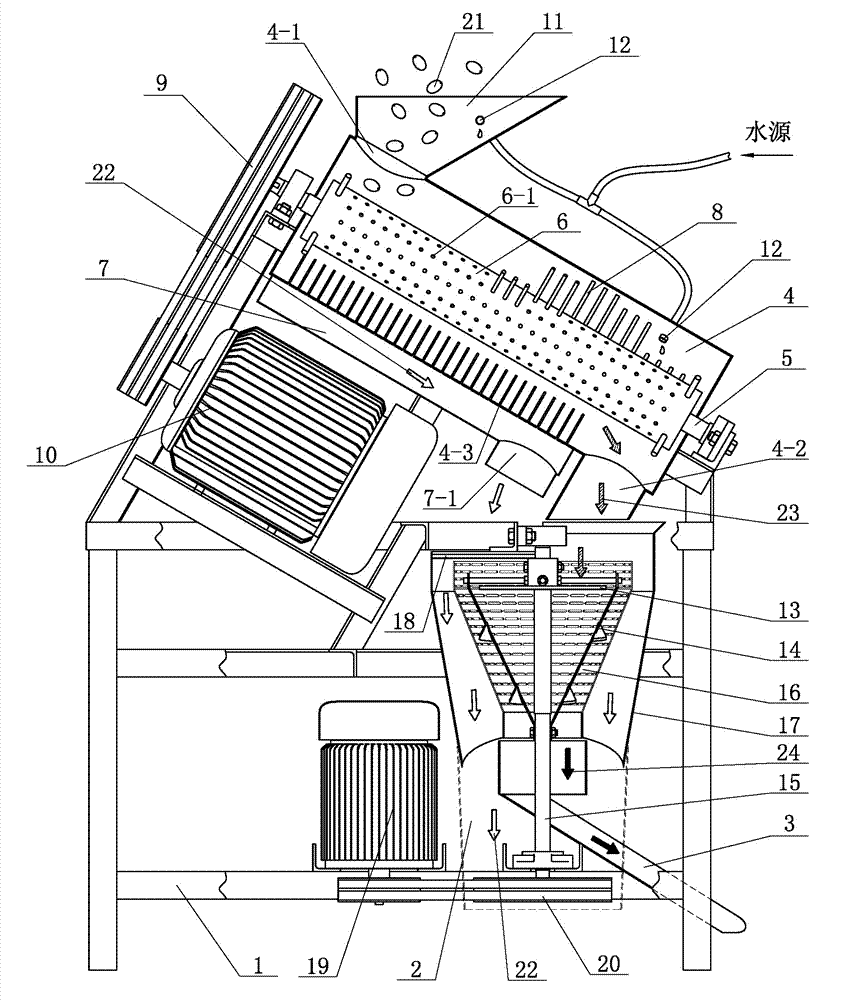

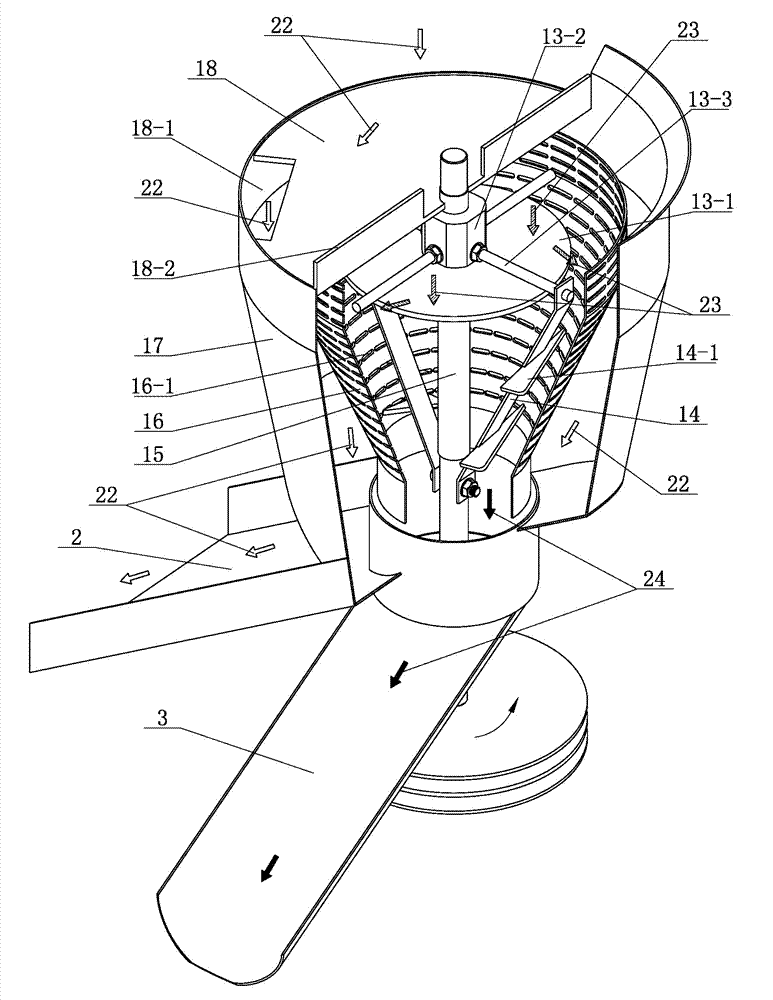

[0019] Such as figure 1 , figure 2 , image 3 , a jujube pitting machine, comprising a breaker and a separator installed on a frame 1.

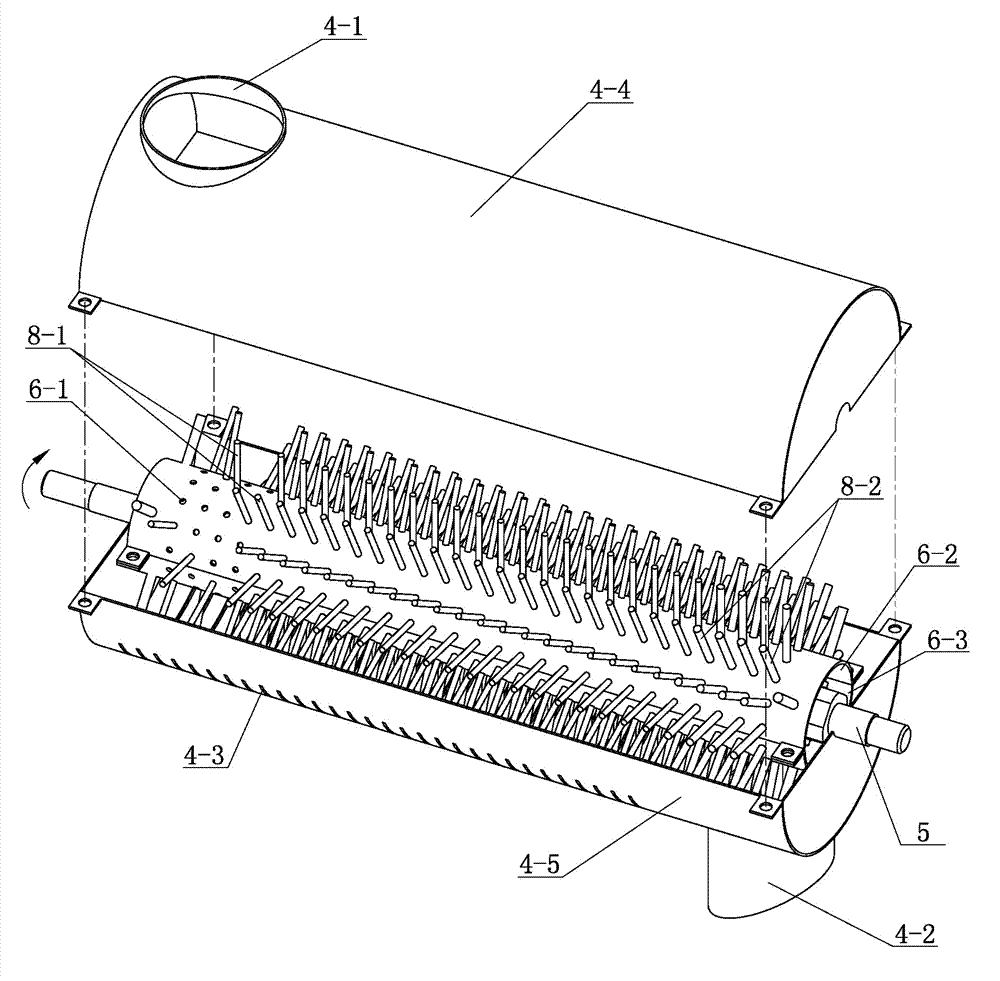

[0020] The crusher includes a rod-type crushing rotor, a crusher outer cylinder 4, and a crushing adapter 7. The crusher outer cylinder is a cylindrical shell provided with a feeding port 4-1 and a discharge port 4-2. The bottom wall of the outer cylinder is provided with a plurality of slits 4-3, and the outer cylinder of the crusher is set on the outside of the rod-type crushing rotor. -1 semi-circular cylinder; the axes of the rod-type crushing rotor, the outer cylinder of the crusher, and the crushing socket are coaxial, called the axis of the crusher, and the crusher is provided with an included angle along the axis of the crusher and the horizontal plane; The discharge port of the outer cylinder of the crusher and the discharge port of the crushing joint are set at the lower end of the crusher, and the feeding port of the outer cyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com