Waterproof leaking stoppage material with self-repairing function

A waterproof plugging and self-repairing technology, applied in the field of building materials, can solve the problems of weakening the repairing and plugging treatment effect, increasing the cost of waterproofing projects, and complicated construction procedures, achieving strong adhesion, fast coagulation, high early mechanical properties and resistance. The effect of osmotic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

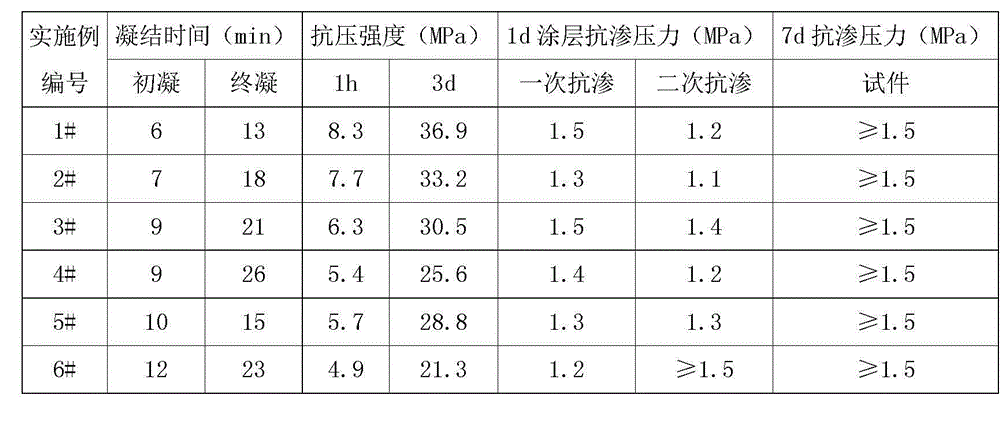

Examples

Embodiment 1-6

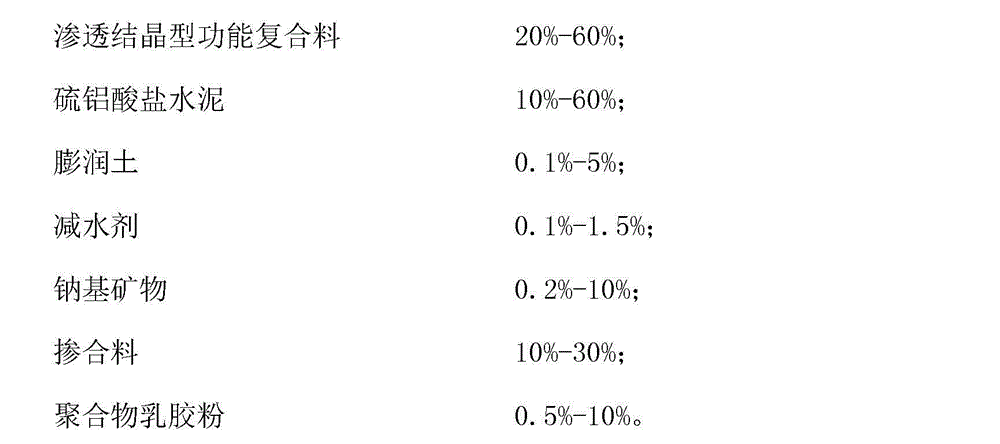

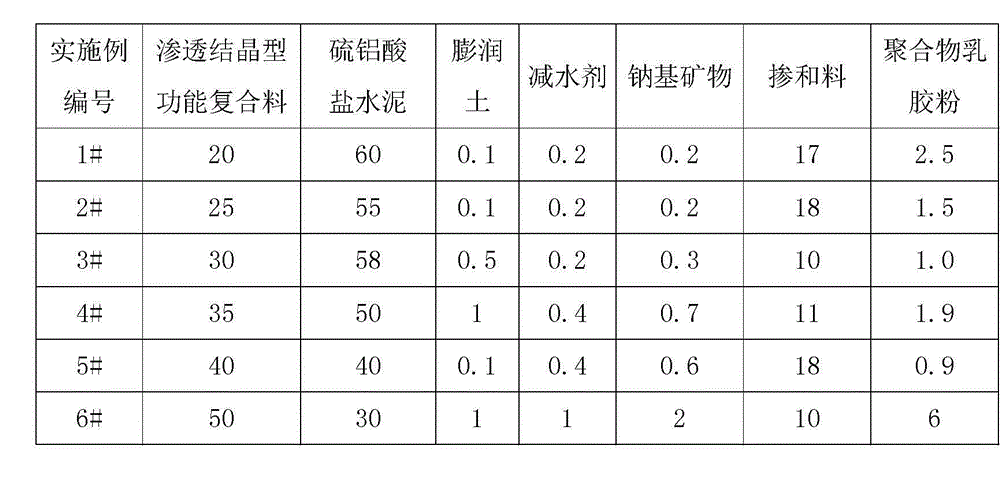

[0024] The specific parts by weight of each raw material in the examples are shown in Table 1.

[0025] Table 1 The parts by weight of each raw material

[0026]

[0027] The preparation method of the above-mentioned waterproof plugging material with self-repairing function, it comprises the steps:

[0028] The selected raw material components are accurately weighed according to the formulated weight ratio plan, and then put into the mixer, and prepared according to 25 kg each time, and the mixing and stirring time is controlled at 10 minutes each time, and this item can be obtained after mixing. Invented and developed waterproof plugging material with self-healing function.

[0029] The osmotic crystalline functional compound is a cement-based osmotic crystalline waterproof material.

[0030] The quality index of the sulphoaluminate cement needs to be above grade 42.5, and the raw material quality meets the index requirements of GB18445-2001 "Cement-Based Penetrating Cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com