Manufacturing method of coated paper for printing

A manufacturing method and technology for coating paper, which are applied in the directions of papermaking, papermaking, textiles and papermaking to achieve the effect of excellent ink drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

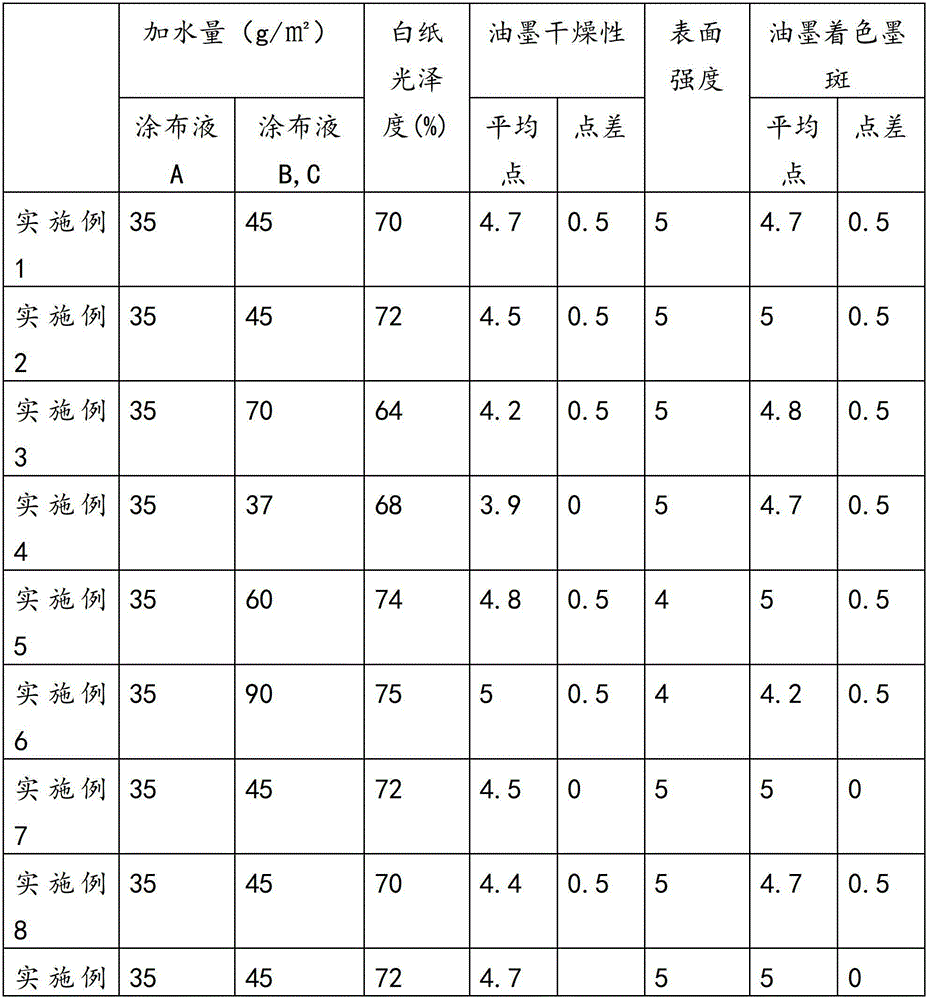

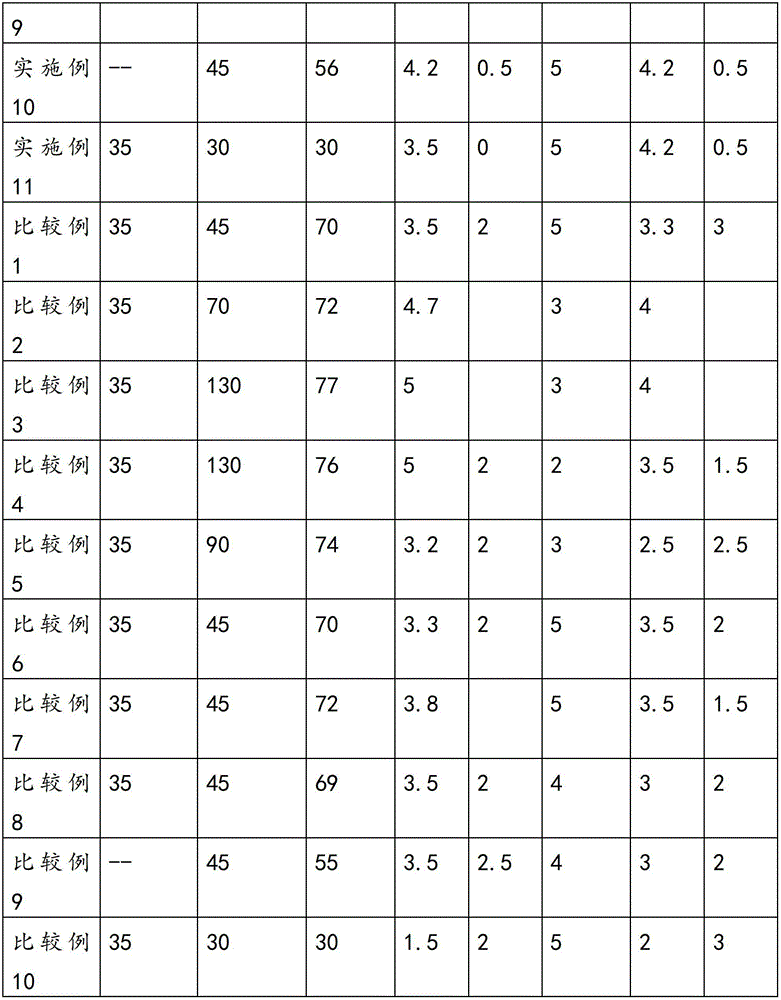

Embodiment 1

[0089] The present invention will be explained below with reference to examples, which should not be construed as limiting the invention. "Parts" and "%" in the examples mean "parts by mass" and "% by mass" unless otherwise specified.

[0090]

[0091] (production of base paper)

[0092] Using a Lo-solids digester (manufactured by ANDRITZ Co., Ltd.), the broad-leaved tree chips consisting of Acacia mangium: Eucalyptus grandis = 30:70 (mass ratio) were subjected to sulfuric acid by the Lo-solids steaming method Salt (craft) cooking. Prepare white liquor with a degree of sulfidation of 28, and add the white liquor to the chip supply system at a rate of 10% active alkali relative to the absolute dry weight of each chip, divide and add 8% to the cooking area, and 2% to the washing area. %, cooking at a cooking temperature of 146°C. The boiled flakes are disentangled (defiberized), then undergo a washing process, a screening process, and then a secondary washing process to obt...

Embodiment 2

[0103] In Example 1, in the drying process after coating the aqueous coating liquid B, after drying the coating layer moisture to 20% with the composite type drying unit, and further drying to 5.0% moisture using a hot air dryer, Coated paper was obtained in the same manner as in Example 1.

Embodiment 3

[0105] In Example 2, except that the coating method of the coating water-based coating liquid A and B is changed from a knife coating method to a roll coating method, and the solid content concentration of the coating liquid B is changed to 60%, the same as the implementation Example 2 The same method was used to obtain coated paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com