Heat accumulating plate and floor heating base plate applying heat accumulating plate as well as preparation method of upper heat conduction plate

A technology of heat storage plate and heat conduction plate, which is applied to manufacturing tools, floors, ceramic molding machines, etc., can solve the problems of long concrete backfill and construction period, low efficiency, heavy floor load, etc., and achieves high construction efficiency and high thermal effect. , the effect of low floor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

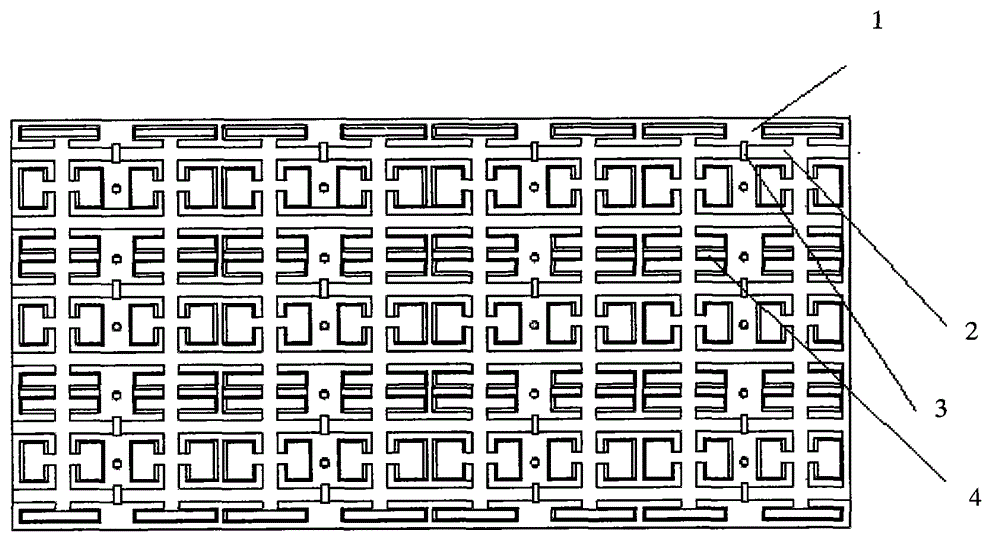

[0085] Combine figure 2 ; The grooves 2 are linearly distributed;

Embodiment 2

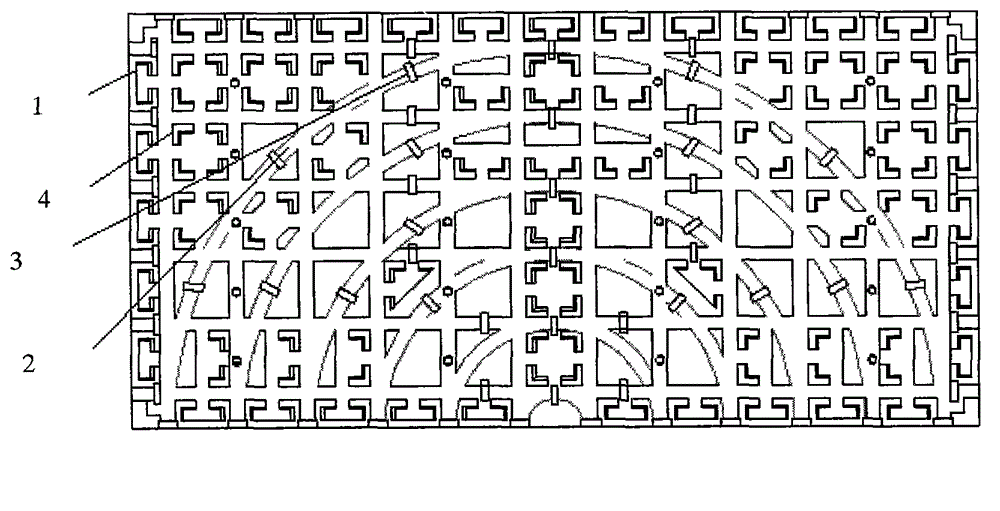

[0087] Combine image 3 , The groove 2 has a curved distribution;

[0088] Combine figure 1 , Which is also an embodiment of the groove 2.

[0089] In addition, the uneven part next to it has two functions:

[0090] (1) Save materials and reduce the overall weight;

[0091] (2) A cavity is formed. After the hot water pipe is heated, the hot and cold air convection makes the whole substrate uniformly heated, and is not limited to the corresponding surface where the heating pipe is located.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap