Front power output gearbox of wheeled tractor adopting hydraulic clutch

A wheeled tractor and hydraulic clutch technology, applied in transmission boxes, mechanical equipment, transmission devices, etc., can solve the problems of complex structure, increased machine mass, loss of transmission efficiency, etc., and achieve the effects of small size, reduced space, and stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

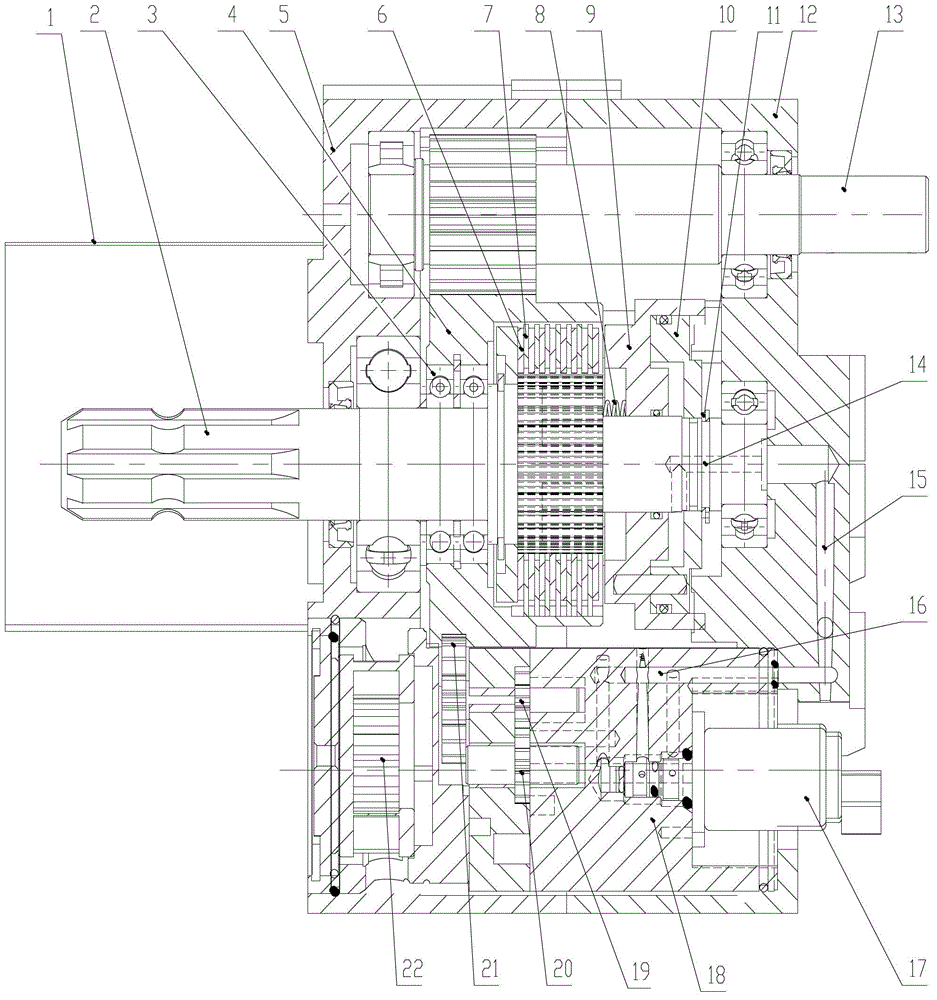

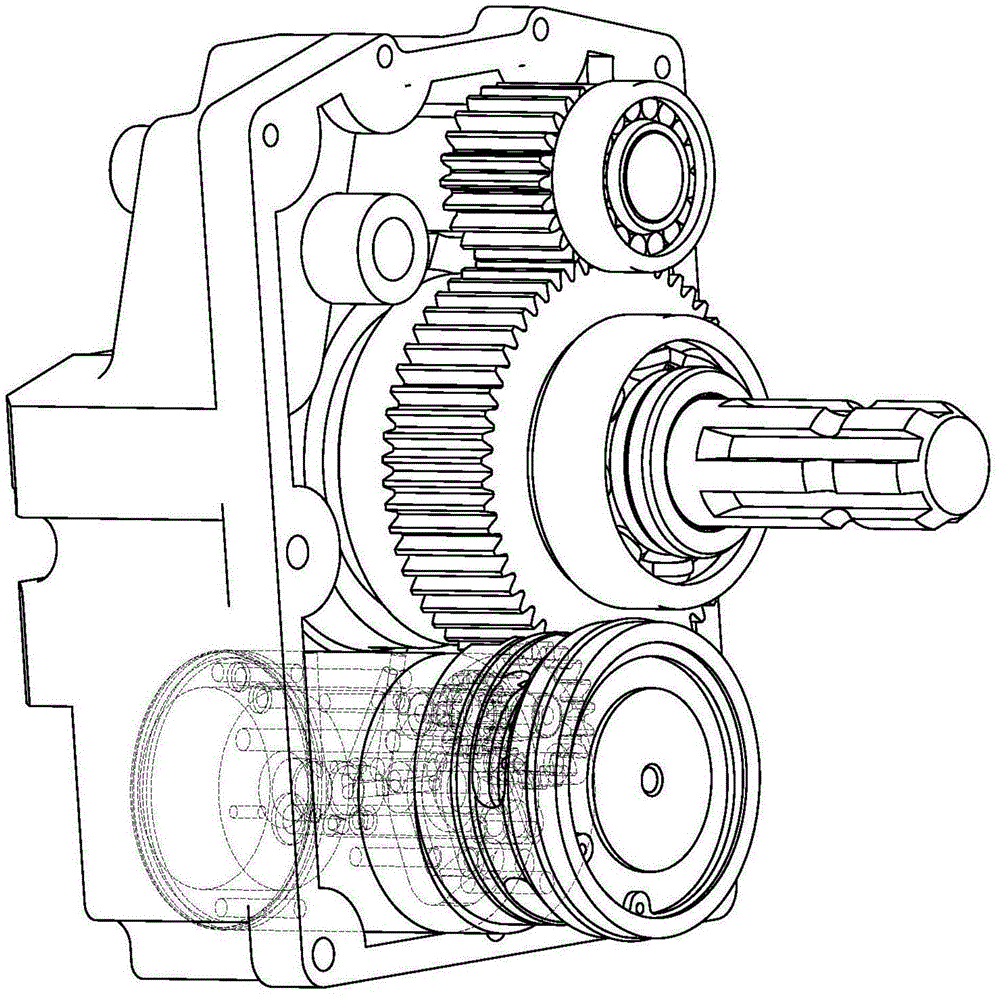

[0023] A wheeled tractor power output transmission adopting a hydraulic clutch, combined with figure 1 , figure 2 , including left casing 5, the casing that right casing 12 forms, is provided with input gear shaft 13, output shaft 2, hydraulic power unit 18 on the casing, and hydraulic power unit 18 is fixed on the casing with bolt. The output shaft 2 is provided with a driven gear 4 near the output end, and the driven gear 4 meshes with the gear on the input gear shaft 13 , and a rolling bearing 3 is arranged between the output shaft 2 and the driven gear 4 . A friction plate 6 and a friction steel plate 7 are installed between the output shaft 2 of the gearbox and the inner chamber of the driven gear 4. The friction plate 6 is connected to the output shaft 2 through a spline, and the friction plate 7 is connected to the driven gear through a spline....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com