Improved waste heat power generation system for cement industry

A technology for cement industry and waste heat power generation. It is used in cement production, waste heat treatment, machinery/engine, etc. It can solve problems such as the reduction of unfavorable solid particles, the large resistance of flue gas removal, and the unfavorable removal and utilization of high-heat flue gas. The effect of heat exchange efficiency and stability, improving economy and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

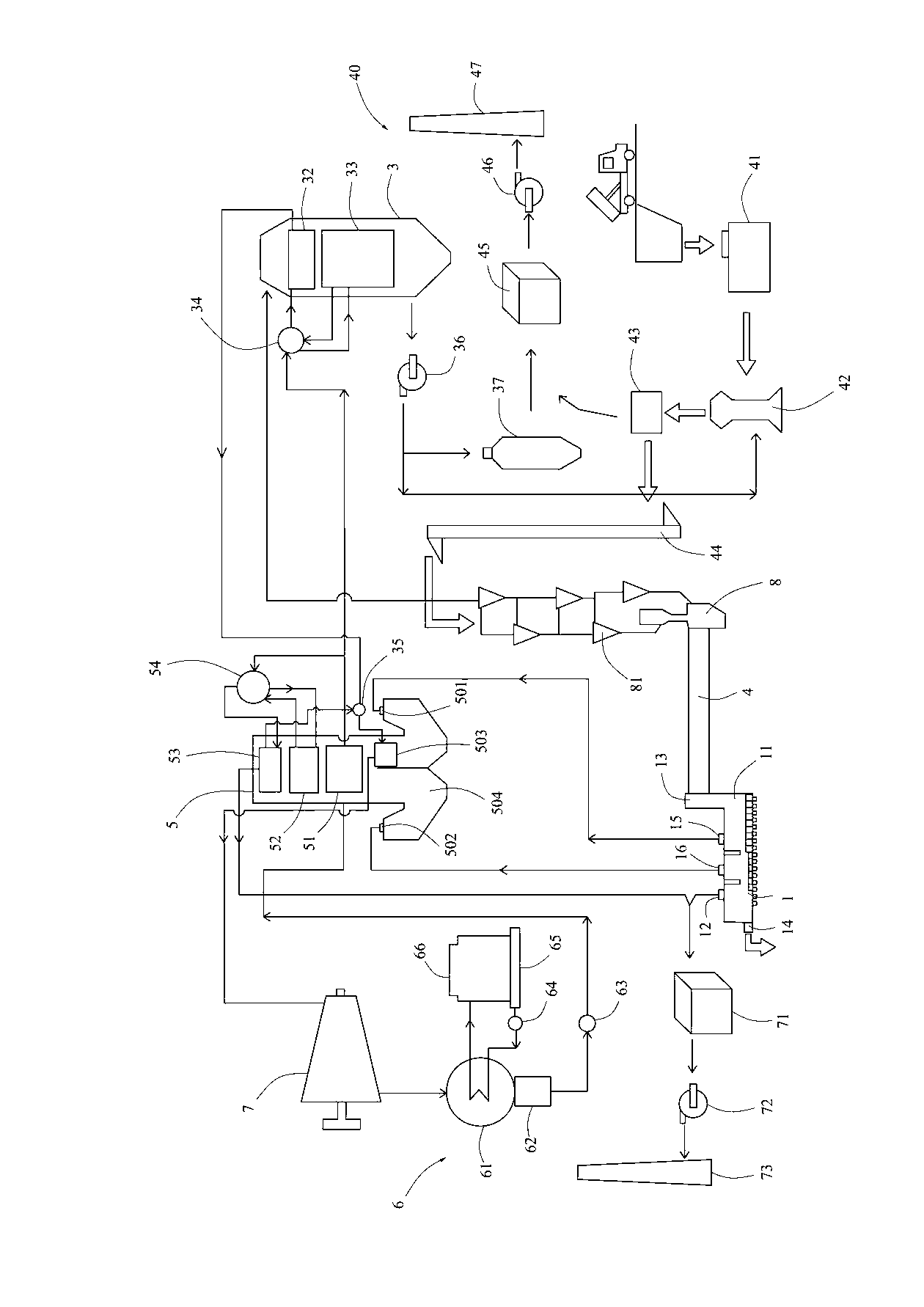

[0012] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0013] refer to figure 1 , The preferred embodiment of the present invention discloses a highly improved waste heat power generation system for the cement industry, including a clinker cooler 1, a kiln tail boiler 3, a kiln head boiler 5, a water supply system 6, and a steam turbine 7. The clinker cooler 1 sends flue gas to the kiln tail boiler 3 and the kiln head boiler 5, and the kiln tail boiler 3 and the kiln head boiler 5 cooperate with the water supply system 6 to generate steam for the steam turbine 7 to do work.

[0014] The clinker cooler 1 cools the cement clinker and generates a large amount of hot flue gas. The clinker cooler 1 has a feed end 11 and a discharge end 12 , a front air outlet 13 is provided near the feed end 11 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com