Split inclined spoke torquer sensor

A torque sensor, split-type technology, applied in the field of torque sensors, to achieve the effect of high strength, strong versatility, and large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

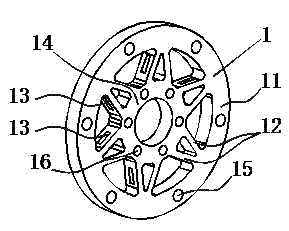

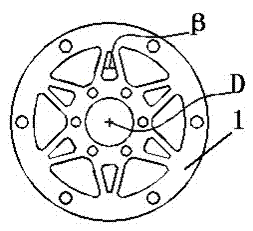

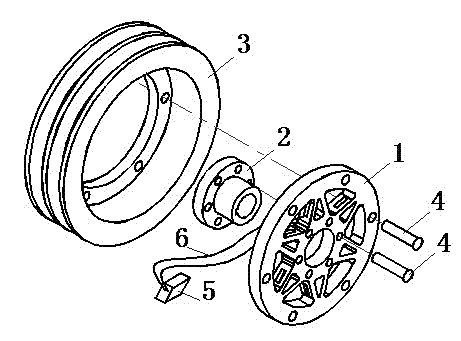

[0023] The sensor includes a disc 1 , an inner hub 2 , an outer ring 3 , rivets or bolts 4 for connection, a strain signal transmission line 6 and a strain signal acquisition module 5 . When in use, the inner hub 2 is connected to the transmission shaft through a flat key or spline, the disc 1 and the inner hub 2, and the disc 1 and the outer ring 3 are connected by rivets or special bolts with positioning function, and the sensor uses the inner hub 2, The disc 1 and the outer ring 3 transmit the torque from the transmission shaft to the belt or chain connected with the outer ring. The structure of the disc 1 includes an inner ring 14, an outer ring 11, inclined spokes 12, an inner ring connecting hole 16, an outer ring connecting hole 15, a center hole aD and strain gauges 13 pasted on the inclined spokes. The inner hub structure includes a central hole bD', a keyway 24, a hub 21, an outer connecting ring 22 and a connecting hole 23 on the outer connecting ring for connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com