Measuring method of Laves phase content of T/P 92 steel

A measurement method and phase content technology, which is applied in the direction of material analysis by measuring secondary emissions, can solve the problems of the small number of Laves phase particles, the distribution is not statistically significant, and the error of quantitative results, achieving a wide range of observation areas and manufacturing Simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The composition is shown in Table 1, and the P92 steel pipe with a specification of φ325mm×71mm is sampled and subjected to aging treatment at 650°C for 5000h, and the Laves phase content in the state T / P92 steel is quantified.

[0041] The chemical composition (wt.%) of table 1 embodiment P92 steel

[0042]

[0043] The assay method comprises the following steps:

[0044] Step 1: Sampling and grinding metallographic samples, and then corroding them with picric hydrochloric acid alcohol solution synthesized by 1g picric acid + 5ml hydrochloric acid + 100ml ethanol, keeping the samples dry and having good electrical conductivity, and preparing samples for SEM observation.

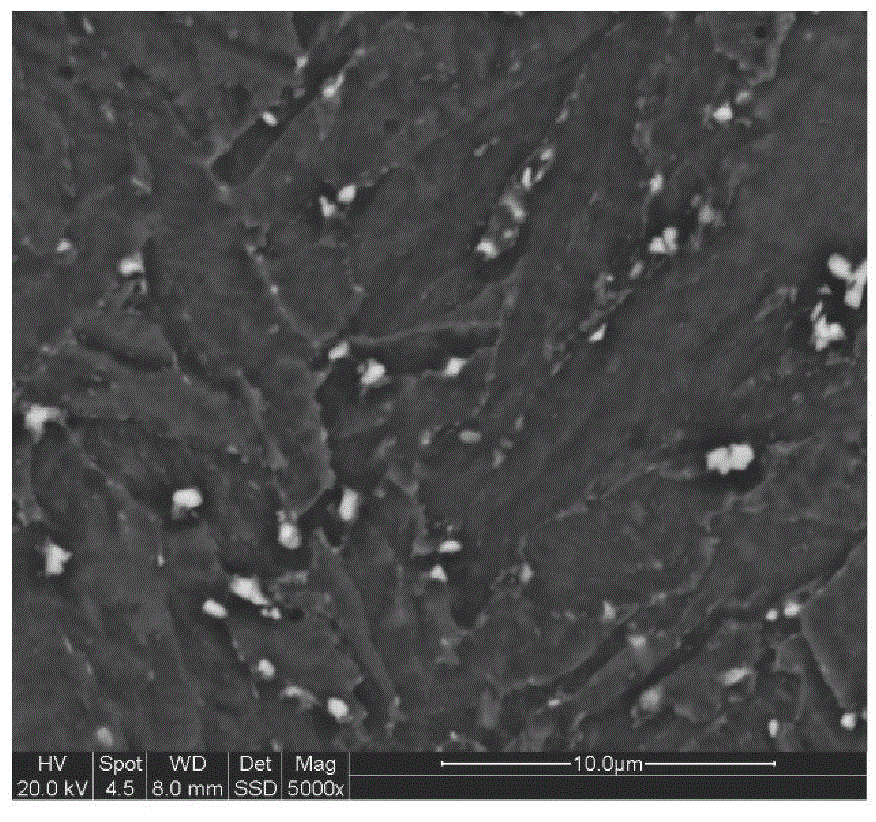

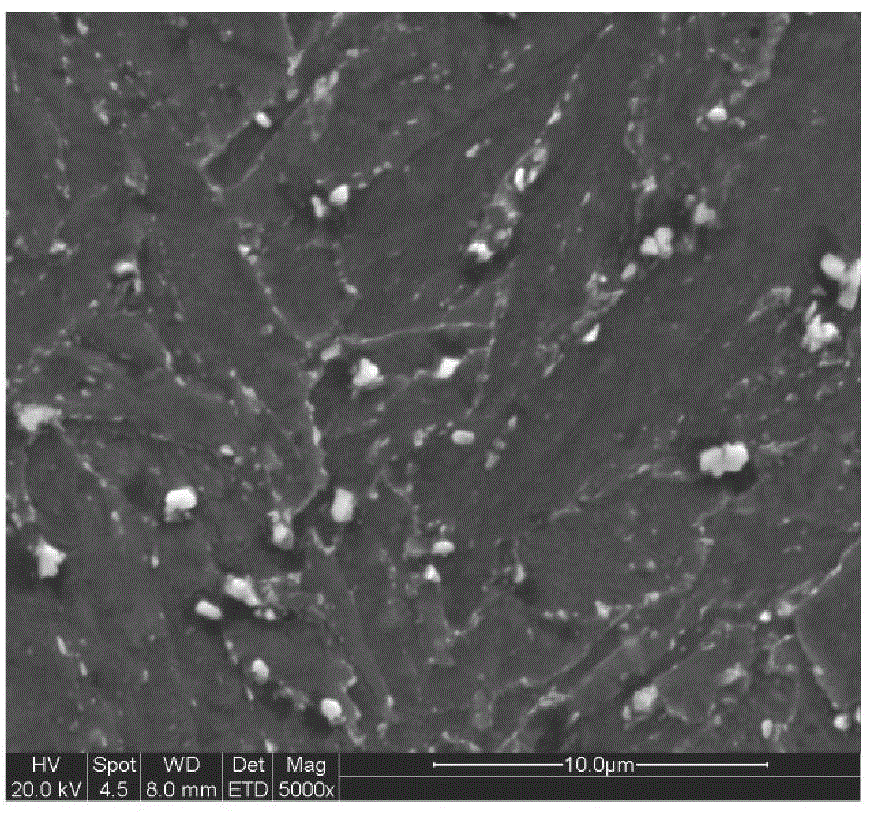

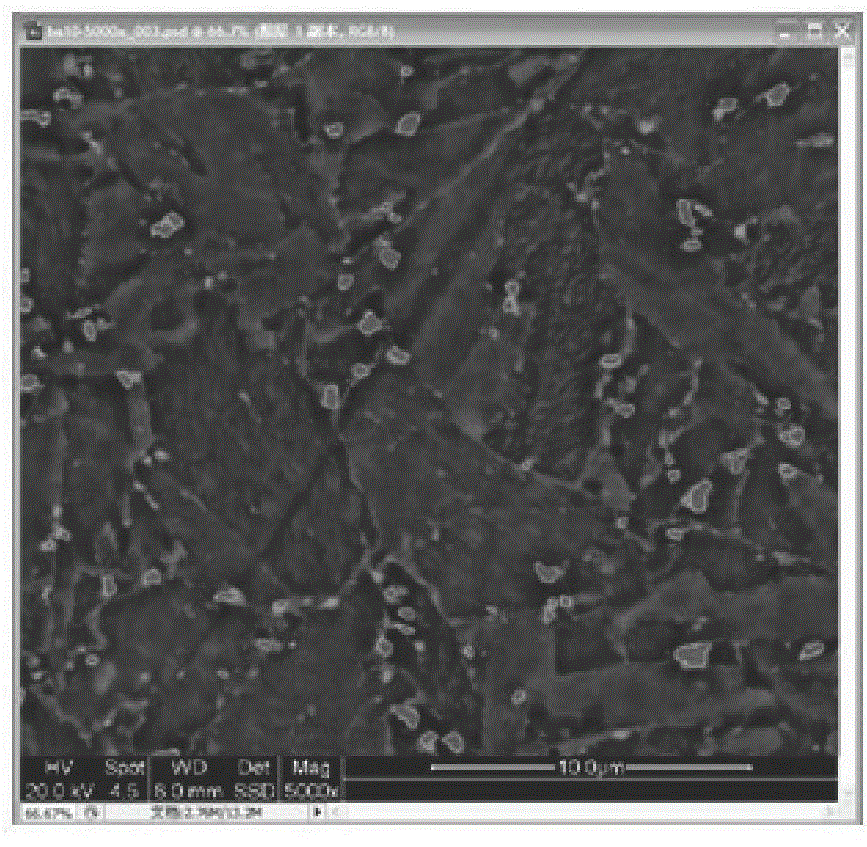

[0045] Step 2, randomly select 6 fields of view to take SE and BSE photos respectively, and the magnification is 5000 times.

[0046] If the magnification is too low, the Laves phase is too small to be observed and identified; if the magnification is too high, the number of Laves phases in the fie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com