High performance liquid chromatography assay method for formaldehyde and acetaldehyde in cigarette filter bead

A high-performance liquid chromatography, cigarette filter technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of measuring cigarette filter burst beads, etc., achieve high sensitivity and accuracy, avoid loss of components and avoid the external environment. Contamination, simple effect of sample preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

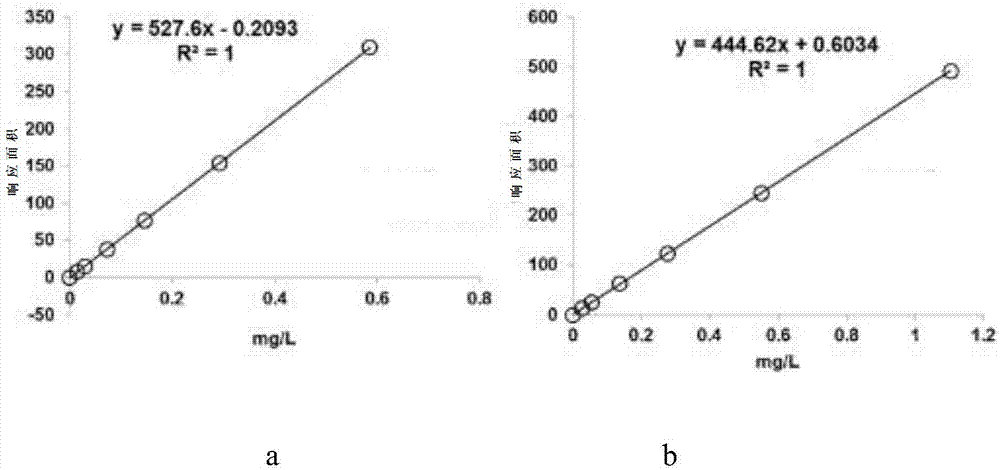

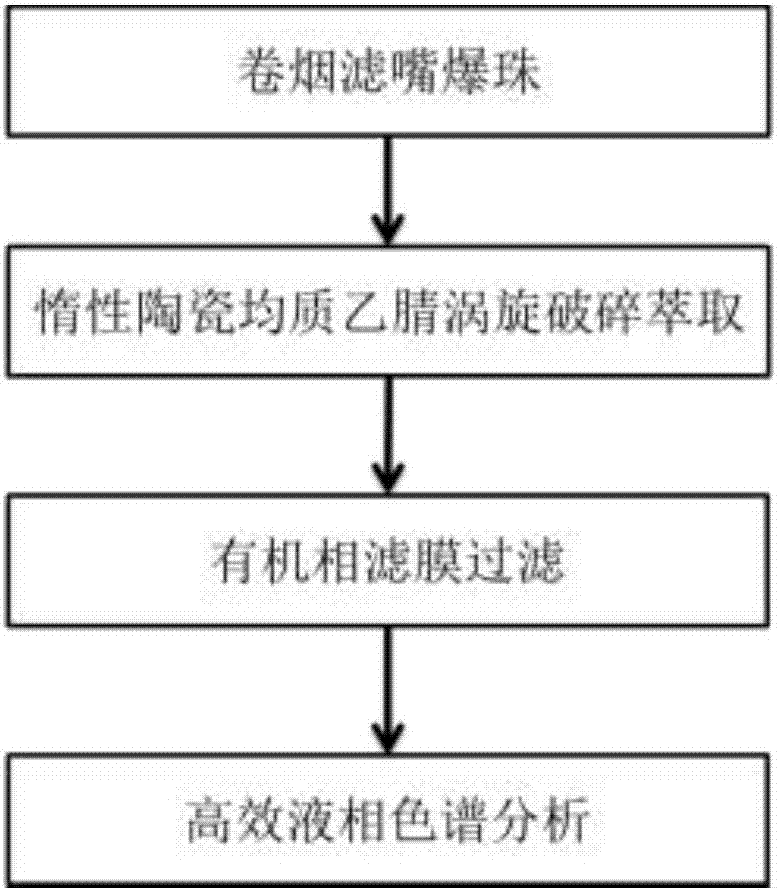

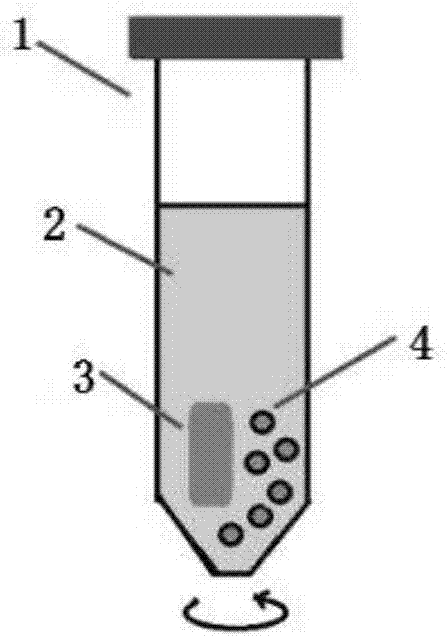

[0034] The high-performance liquid chromatography assay method of formaldehyde and acetaldehyde in the cigarette filter quick-fried beads of the present embodiment, such as figure 1 shown, including the following steps:

[0035] 1) Preparation of 2,4-dinitrophenylhydrazine derivatization reagent

[0036] Purification of 2,4-dinitrophenylhydrazine: Weigh 12g of 2,4-dinitrophenylhydrazine into a 250mL round bottom flask, add 200mL of acetonitrile, heat to dissolve at 130°C and reflux for 2h, then transfer to a beaker and seal After standing overnight, the obtained crystals were suction filtered and washed, dried in a vacuum oven, and finally sealed in a brown bottle for future use.

[0037] Preparation of 2,4-dinitrophenylhydrazine derivatization reagent: Weigh 0.01g of purified 2,4-dinitrophenylhydrazine into a 100mL brown volumetric flask, add 5mL of phosphoric acid, and dilute to volume with acetonitrile to obtain the product.

[0038] 2) Preparation of test solution

[00...

experiment example

[0070] According to the method of embodiment 1, the cigarette filter popping beads sample is analyzed, and the obtained chromatogram is as follows Figure 5 shown, where Figure 5 The chromatographic peak at 6 is the chromatographic peak of acetaldehyde-2,4-dinitrophenylhydrazone. The recovery and precision experiments were carried out with the 3-level standard addition method, and the determination was repeated 5 times for each standard addition level. The recovery and repeatability results of the detection method are shown in Table 3. It can be seen from Table 3 that the recovery rate and repeatability data are ideal, the recovery rates of the three spiked levels are between 81.1-107.8%, and the relative standard deviation (RSD) is 0.7-1.3%, which can meet the needs of quantitative analysis.

[0071] Table 3 Detection method recovery rate and repeatability

[0072]

[0073] In other embodiments of the present invention, the preparation of the liquid to be tested can als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com