Flat panel display, front frame structure and manufacturing method thereof

A flat-panel display and manufacturing method technology, applied in rack/frame structures, instruments, optics, etc., can solve the problems of overly heavy flat-panel displays, not conforming to market trends, and increased production costs, so as to reduce processing procedures and production costs, The effect of improving production efficiency and increasing the strength of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

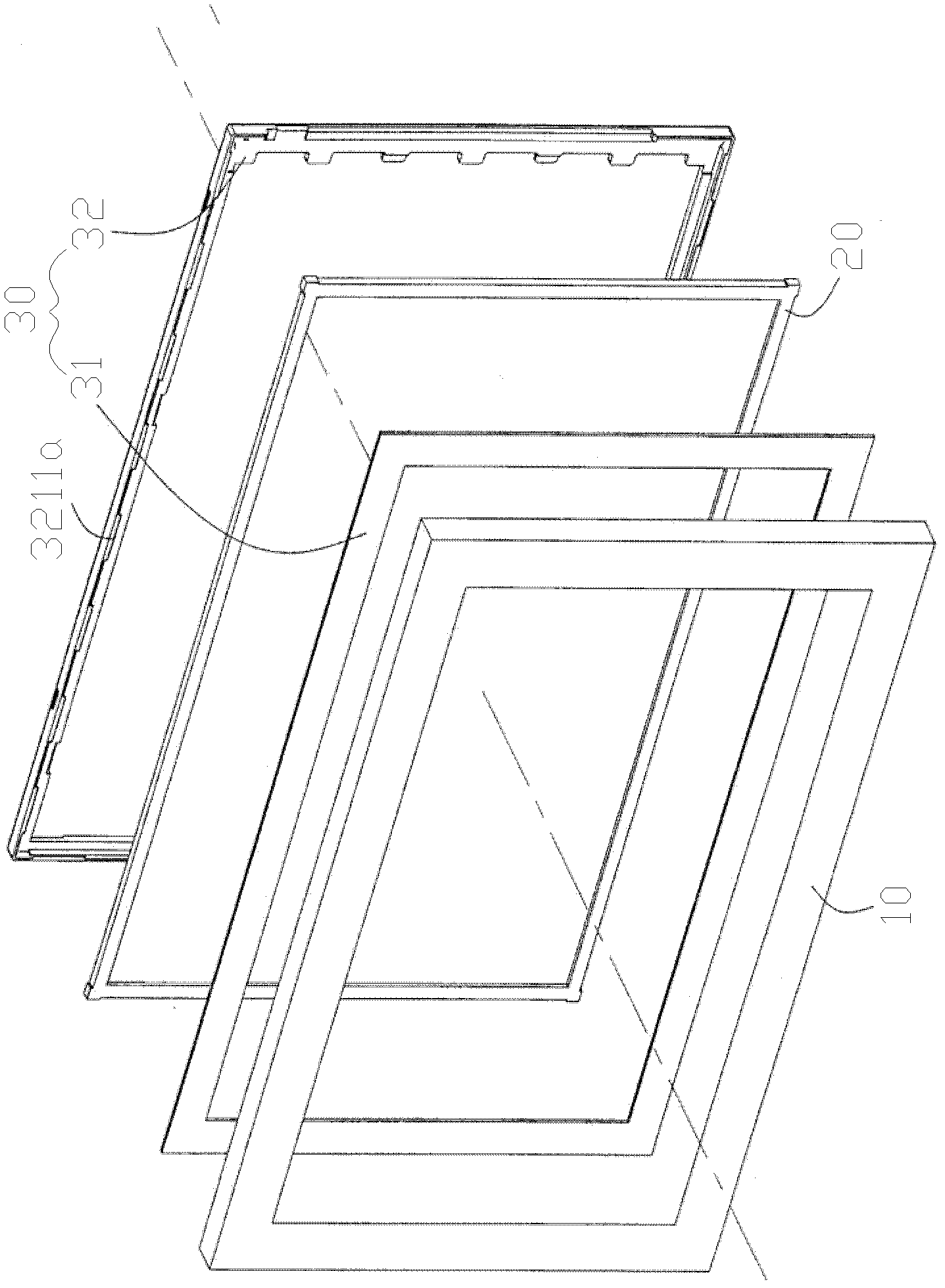

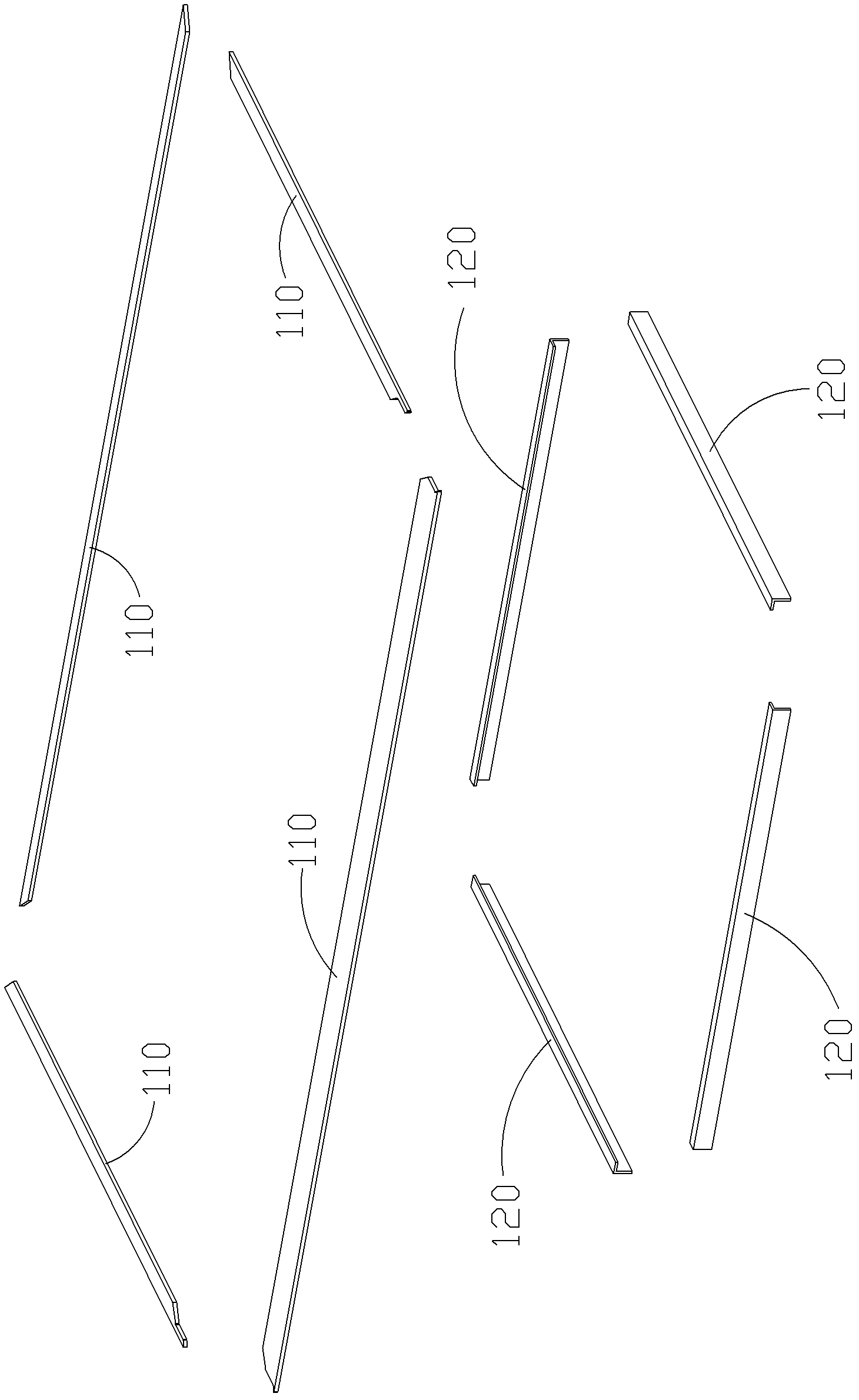

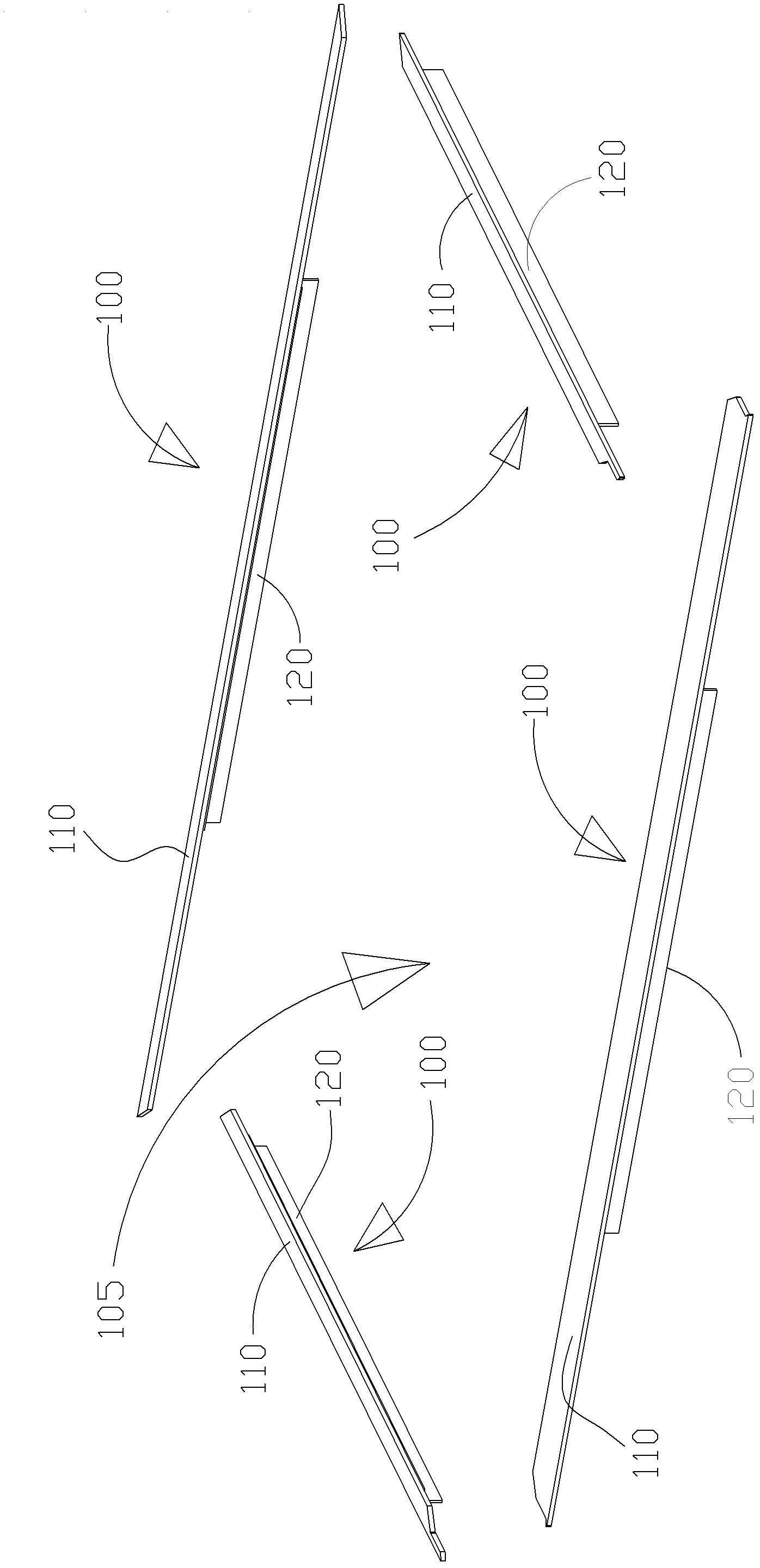

[0055] see Figure 2A , Figure 2B and Figure 2C , which are respectively an exploded view, a perspective view and a schematic plan view of the front frame assembly of the front frame structure of the first embodiment of the present invention. As shown in the figure, the front frame structure of the present invention includes a plurality of front frame assemblies 100, each front frame assembly 100 includes a body 110 and at least one limiting member 120, and the limiting member 120 includes a connecting portion 122 And a limiting part 124, the fixed part 122 forms a bonding part 126 through laser welding, ultrasonic welding or welding, etc., and is bonded to the main body 110. The limiting part 124 is erected on the main body 110, and each front frame The components 100 are connected to the main body 110 respectively, and an opening 105 is formed around each front frame component 100 .

[0056] In this embodiment, the fixed portion 122 and the limiting portion 124 are perp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com