B<3+>, Al<3+>, Mg<2+>, Y<3+> and S<2-> co-doped solid electrolyte Li7La3Zr2O12

A solid electrolyte and co-doping technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems that researchers have figured out, and achieve the effects of increasing the number, promoting lithium ion migration, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

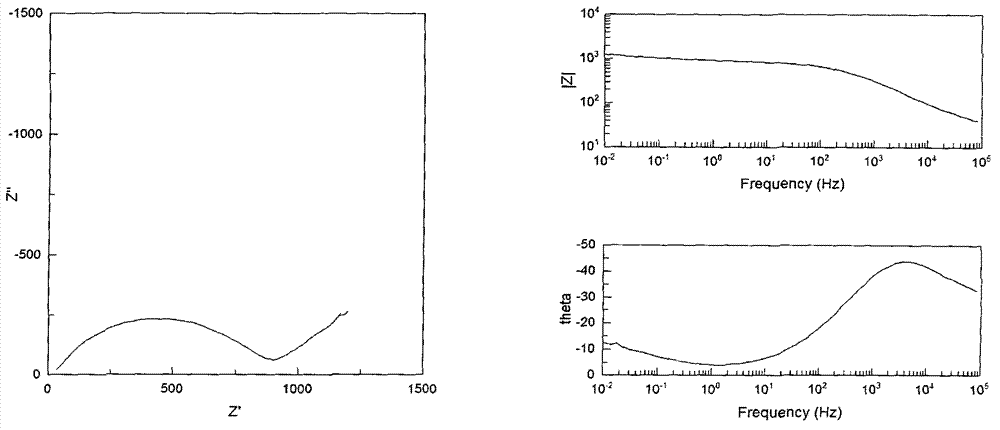

Image

Examples

Embodiment 1

[0011] Embodiment 1: Li 2 CO 3 : Y 2 o 3 : La 2 o 3 :B 2 o 3 :Al 2 o 3 :MgO:ZrO 2 : thiourea is 3.7: 0.05: 1.45: 0.05: 0.05: 0.1: 1.7: 0.1 (molar ratio) ratio is evenly mixed, adds 2% 95% ethanol, ball mills 10 hours with the rotating speed of 250 rev / mins in ball mill, After ball milling, dry in a 60°C vacuum oven (vacuum degree 20Pa) for 10 hours, take it out and re-grind in an agate mortar for 15 minutes, and heat up the ground powder to 200°C at a rate of 5°C / min for 3 hours. Then heat up to 750°C at a rate of 5°C / min and keep warm for 6 hours, then heat up to 1150°C at a rate of 3°C / min and keep warm for 20 hours to make solid electrolyte powder. The powder is mixed with 2wt% binder PVC and kept under a pressure of 300MPa under a press for 5 minutes to form a thin sheet, which is heated to 1220°C at a rate of 11°C / min and kept for 10 hours in an air atmosphere to make a lithium ion solid Electrolyte sheets.

Embodiment 2

[0012] Embodiment 2: Li 2 CO 3 : Y 2 o 3 : La 2 o 3 :B 2 o 3 :Al 2 o 3 :MgO:ZrO 2 : thiourea is 4.0: 0.15: 1.35: 0.1: 0.1: 0.3: 1.3: 0.3 (molar ratio) ratio is evenly mixed, adds 5.5% 95% ethanol, ball mills 15 hours with the rotating speed of 380 rev / mins in ball mill, After ball milling, dry in 80°C vacuum oven (vacuum degree 95Pa) for 30 hours, take it out and re-grind in agate mortar for 20 minutes, and heat up the ground powder to 220°C at a rate of 6°C / min for 5 hours. Then the temperature was raised to 780°C at a rate of 8°C / min and kept for 10 hours, and then the temperature was raised to 1200°C at a rate of 7°C / min for 15 hours to make a solid electrolyte powder. The powder is mixed with 5wt% binder PVC and kept under a pressure of 450MPa under a press for 2 minutes to form a thin sheet. The thin sheet is heated to 1280°C at a rate of 15°C / min and kept for 10 hours in an air atmosphere to make a lithium-ion solid electrolyte. Flakes.

Embodiment 3

[0013] Embodiment 3: with Li 2 CO 3 : Y 2 o 3 : La 2 o 3 :B 2 o 3 :Al 2 o 3 :MgO:ZrO 2 : thiourea is 3.85: 0.1: 1.4: 0.075: 0.075: 0.2: 1.5: 0.2 (molar ratio) ratio is uniformly mixed, adds 3% 95% ethanol, ball mills 20 hours with the rotating speed of 300 rev / mins in ball mill, After ball milling, dry in a 70°C vacuum oven (vacuum degree 50Pa) for 20 hours, take it out and re-grind in an agate mortar for 10 minutes, and heat up the ground powder at a rate of 9°C / min to 250°C for 5 hours. Then the temperature was raised to 800°C at a rate of 10°C / min and kept for 7 hours, and then the temperature was raised to 1250°C at a rate of 2°C / min for 12 hours to make a solid electrolyte powder. The powder is mixed with 1wt% binder PVA and kept under a pressure of 300MPa under a press for 6 minutes to form a thin sheet, which is heated to 1300°C at a rate of 15°C / min and kept for 18 hours in an air atmosphere to make a lithium ion solid Electrolyte sheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com