Electrochemical deburring processing method for turbine disc mortises and special device thereof

A special device, the technology of the turbine disk, which is applied in the field of electrochemical deburring of the tongue and groove of the turbine disk, can solve the problems of high cost, low efficiency of polishing and rounding processing, unstable quality, etc., so as to improve the surface quality of parts and reduce the labor of workers. Strength, the effect of improving surface integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

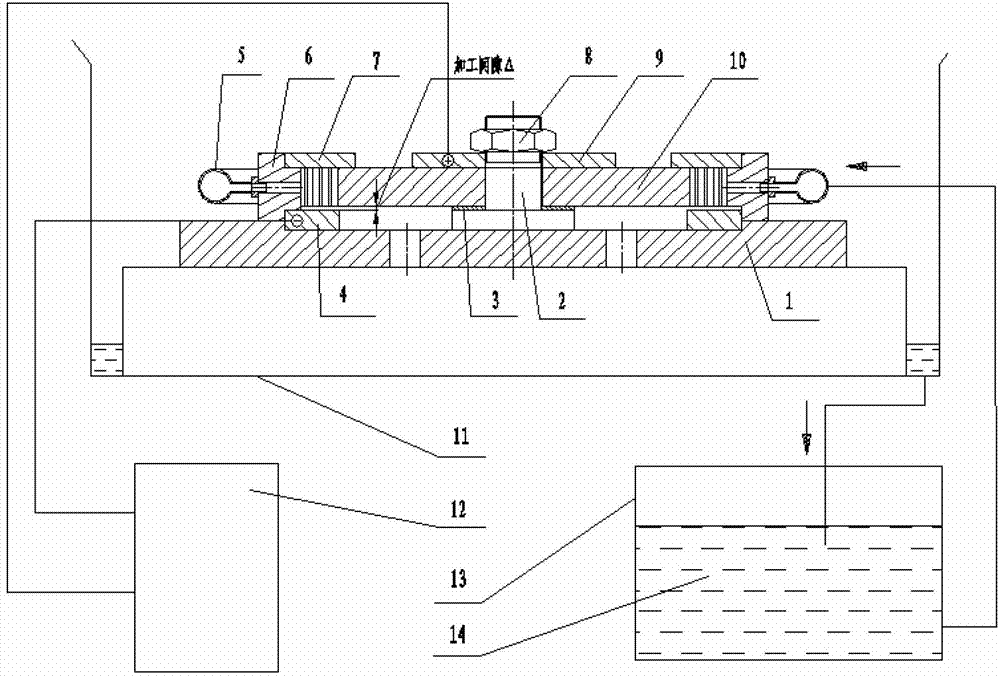

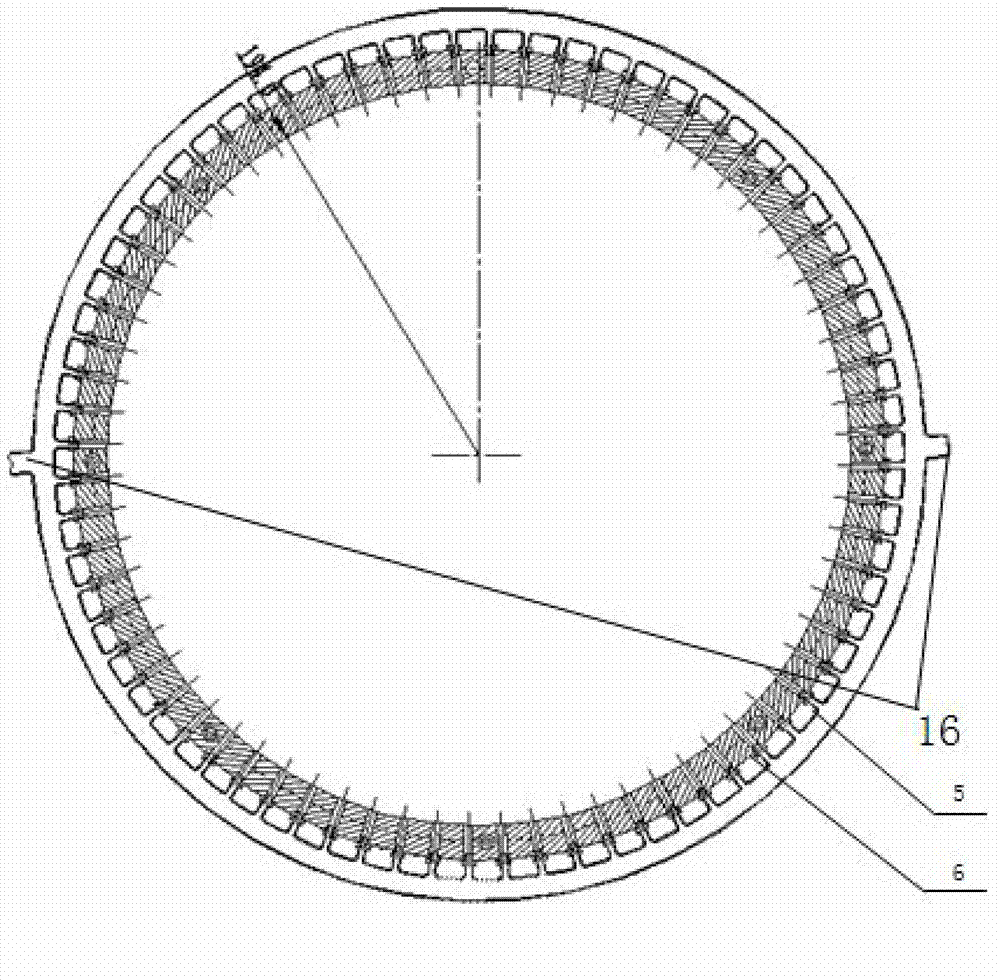

[0047] Such as figure 1 As shown, the electrochemical deburring processing device includes a power supply 12, a working box and a base 11, a fixed cathode 4, a workpiece clamping and positioning system, and an electrolyte supply system. The fixed electrode 4 and the clamping and positioning system have the functions of conduction, positioning, clamping, and forming an electrolyte flow field, etc., and are used for clamping the workpiece to be processed, that is, the turbine disk 10, to realize electrochemical deburring. The power supply 12 is a DC power supply for providing stable current required for processing. The electrolyte supply system provides a certain temperature, concentration, and clean electrolyte, and removes electrochemical products.

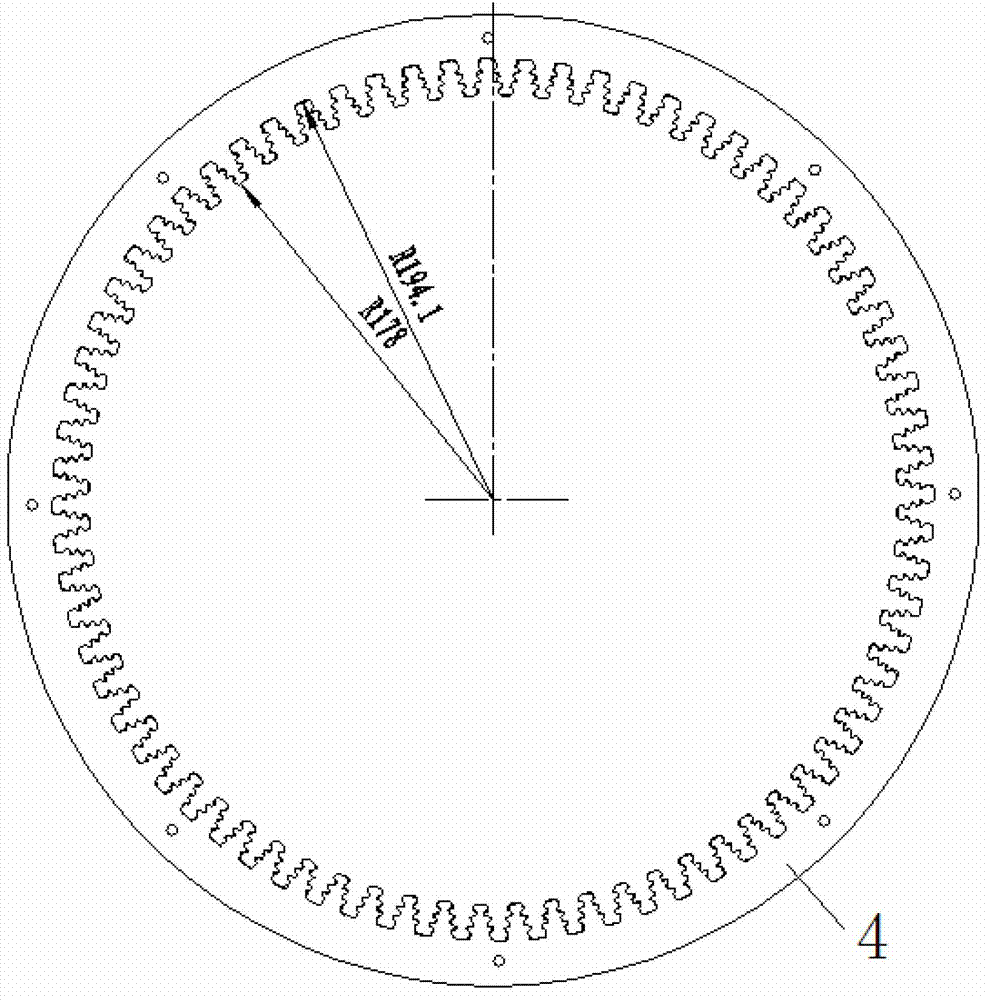

[0048] figure 2 Shown is a fixed cathode 4, which adopts a monolithic structure and is made of stainless steel, on which a plurality of fir-tree-shaped electrodes opposite to the tongue-and-groove structure of the workpiece are...

Embodiment 2

[0058] A method for electrochemically deburring the tongue and groove of a turbine disk, the specific processing steps are as follows:

[0059] ① Position and clamp the parts of the turbine disk 10 to be processed on the fixture. It is required that the tenon and groove of the turbine disk 10 be aligned with the fixed cathode 4, and adjust the distance between the tenon and groove edge of the turbine disk 10 and the fixed cathode 4 according to the process requirements. gap;

[0060] ② Connect the turbine disk 10 to the positive pole of the power supply 12 , and connect the fixed cathode 4 to the negative pole of the power supply 12 .

[0061] ③ Pass the flowing electrolyte between the tenon and groove of the turbine disk 10 and the fixed cathode 4, and turn on the power, start the deburring electrochemical machining, and control the corresponding machining time;

[0062] ④ Turn off the power, turn over the turbine disk 10, and repeat the above steps to process the other side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com