Cold-warm air exchange system based on high-efficiency motor driving for automobile

A motor-driven, air-exchange technology, applied in air-conditioning systems, heating and ventilation control systems, heating and ventilation safety systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

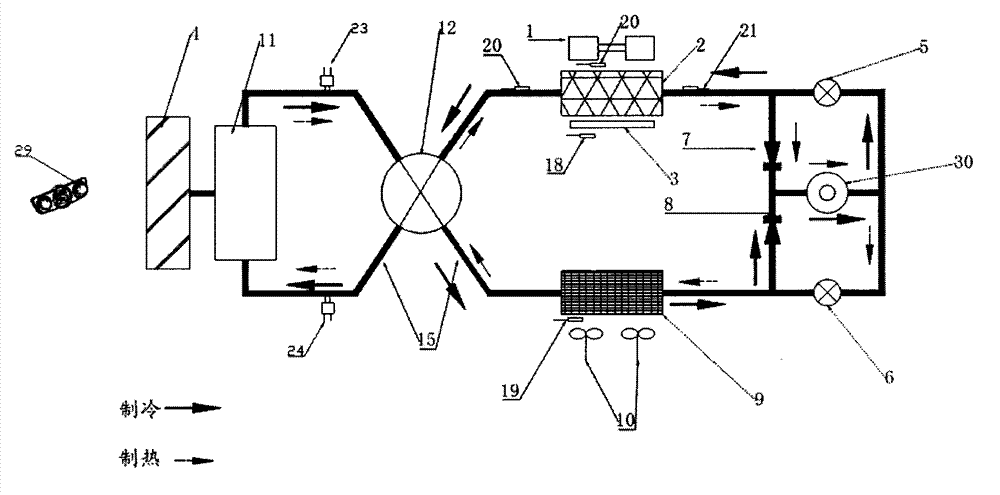

[0010] Depend on figure 1 Known, the vehicle cooling and heating air exchange system driven by high-energy-efficiency motors includes an evaporator 2, a condenser 9, an electric compressor 11, a four-way reversing valve 12 and a dry liquid storage tank 30; they are connected by a pipeline 15 It forms a closed system and is set in a box. The four-way reversing valve 12 is controlled by the electronic control system. One end is respectively connected with the inlet and outlet of the four-way reversing valve 12, and the other inlet and outlet is connected with the dry liquid storage tank 30 through a one-way valve to realize the conversion of cooling and heating of the system. It is characterized in that: the refrigeration is a refrigerant After being vaporized in the evaporator 2, it enters the electric compressor 11. The numerical control panel 29 of the electronic control system calculates the temperature and pressure parameters measured by each sensor, and instructs the compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com