Method for inhibiting grease in alkaline washing towers

A technology of alkali washing tower and butter, which is applied in chemical instruments and methods, purification/separation of hydrocarbons, hydrocarbons, etc., and can solve problems such as poor inhibition effect of butter, easy blockage of alkali washing tower, inconvenient operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

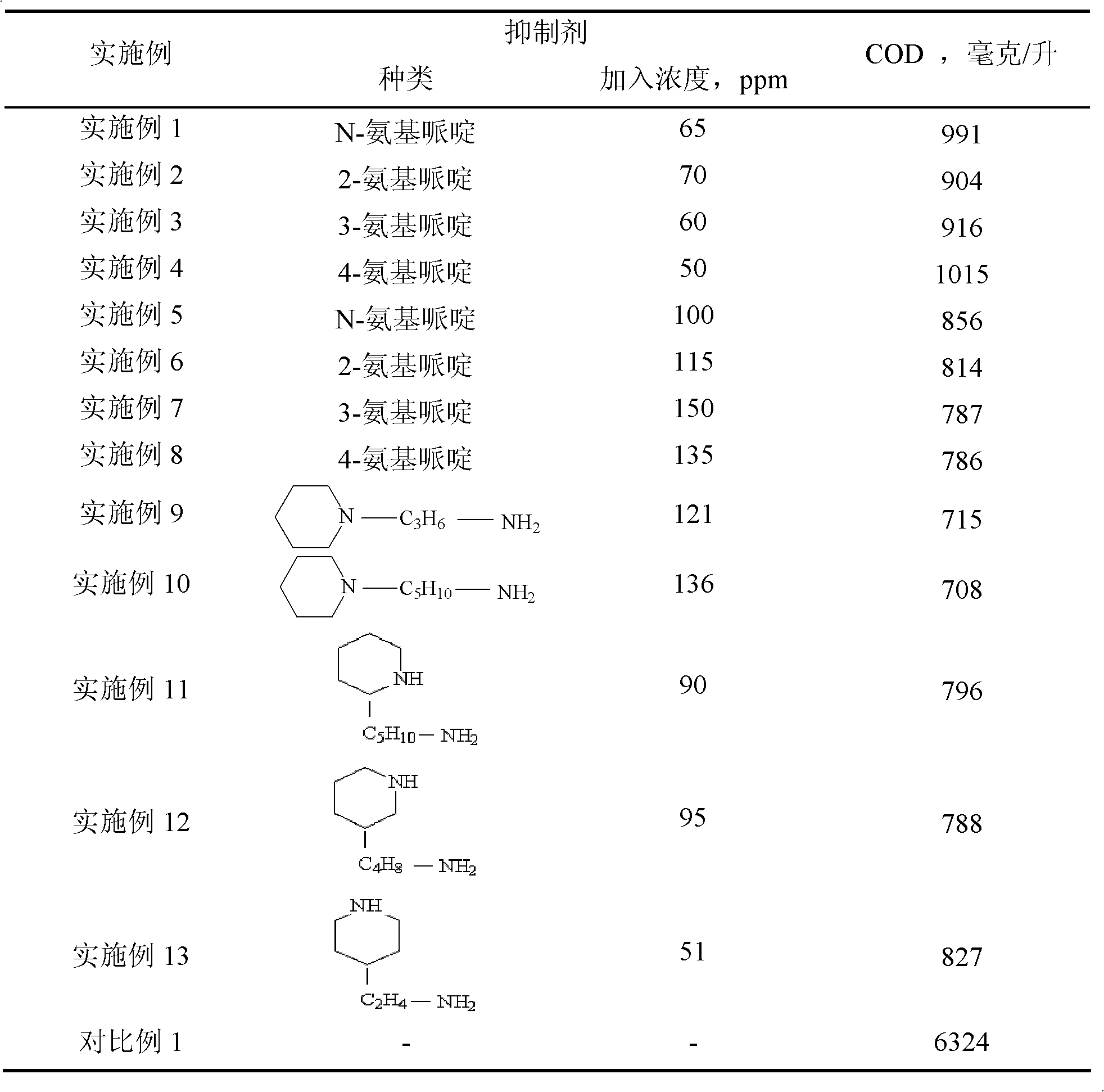

Examples

Embodiment 1

[0012] Apply the inhibitor to the alkali washing tower of the ETO plant, wherein the molar composition of the materials entering the alkali washing tower is: ethylene 49.1%, water 50.25%, acetaldehyde 0.05%, ether 0.01%, C 3 + Hydrocarbon 0.58%, CO 2 0.01%. Alkali washing tower lye temperature is 45°C, lye (NaOH) concentration is 10%, the inhibitor N-aminopiperidine is continuously injected into the lye circulation line using a piston pump, and the injection concentration is 65ppm. After 30 days of operation of the device, no Tower blocking occurs. Adopt the testing method of GB8978-1996 to test that the COD value in the lye is 991 mg / liter, and the results are shown in Table 1.

Embodiment 2~13

[0014] According to each step of [Example 1], only the inhibitors added and their concentrations are different. The specific results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com