Matte thermoplastic elastomer composition and preparation method thereof

A thermoplastic elastomer and composition technology, applied in the field of matte thermoplastic elastomer composition and its preparation, can solve the problems of reduced material fluidity, no visual sense, not very good matte effect, etc., and achieve processing flow Good performance and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

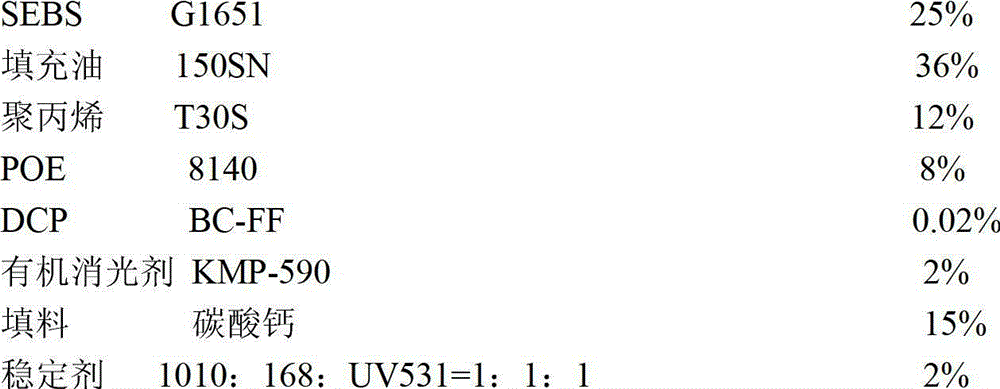

Embodiment 1

[0020] Mix the block styrene copolymer, extender oil, polypropylene, olefinic thermoplastic elastomer filler, organic matting agent, crosslinking agent, stabilizer and other components in a high-speed mixer according to the following weight percentages for 30 minutes, mix evenly, and then Mix in a low-speed mixer for 20 minutes. The uniformly mixed material is fed into the twin-screw extruder by a metering feeder. The temperature is set at 190°C-230°C. at 28 Hz. The mixed raw materials are obtained through high-temperature shearing, melting, plasticizing, mixing, and water ring cutting of a twin-screw extruder.

[0021]

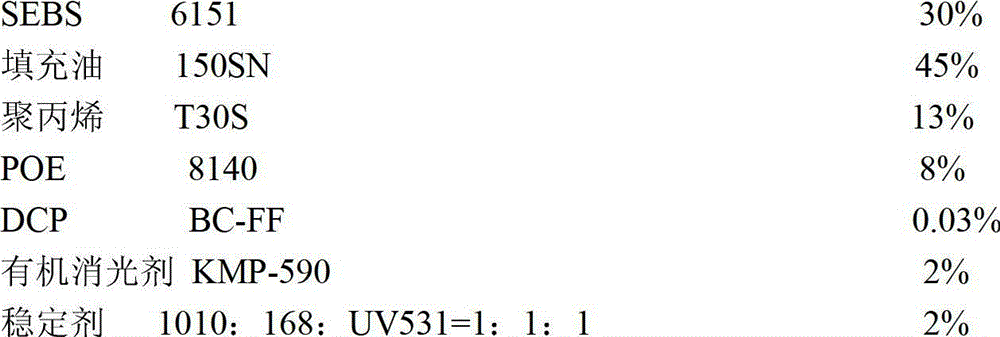

Embodiment 2

[0023] Granulate according to the manufacturing process in Example 1 and the following raw material weight percentages.

[0024]

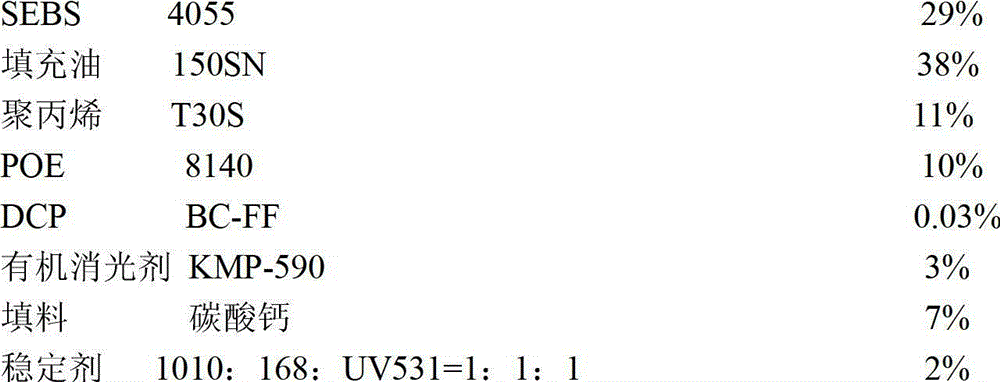

Embodiment 3

[0026] Granulate according to the manufacturing process in Example 1 and the following raw material weight percentages.

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com