Production line system for cleaning alumina crusting blocks

A kind of alumina production line technology, applied in the production line system field of "double carbon block anode level" electrolyte crust block cleaning, can solve the problems of double carbon block anode cleaning production, etc., to achieve easy operation, automatic operation, and stable transmission , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. It should be noted that the present invention is not limited to the following examples.

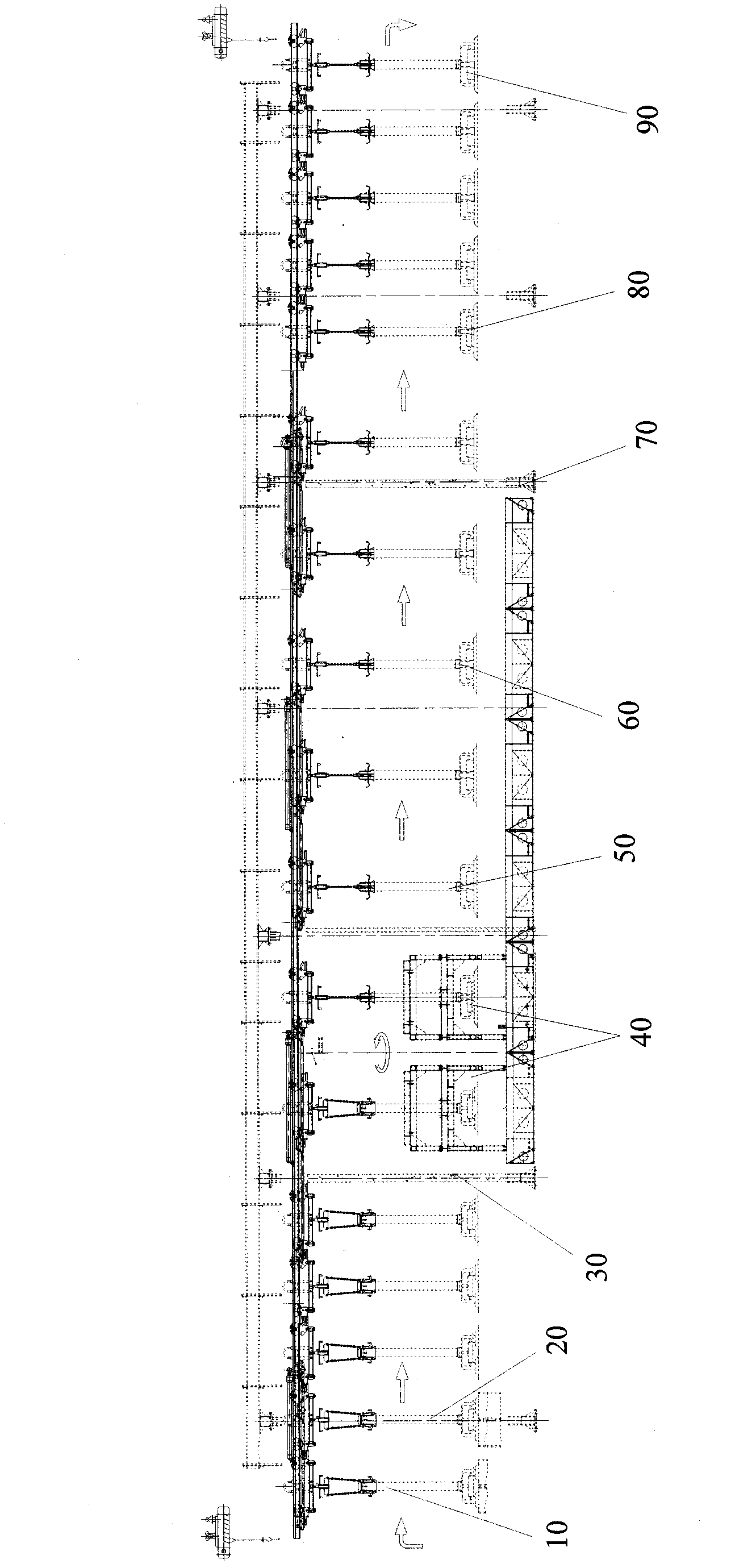

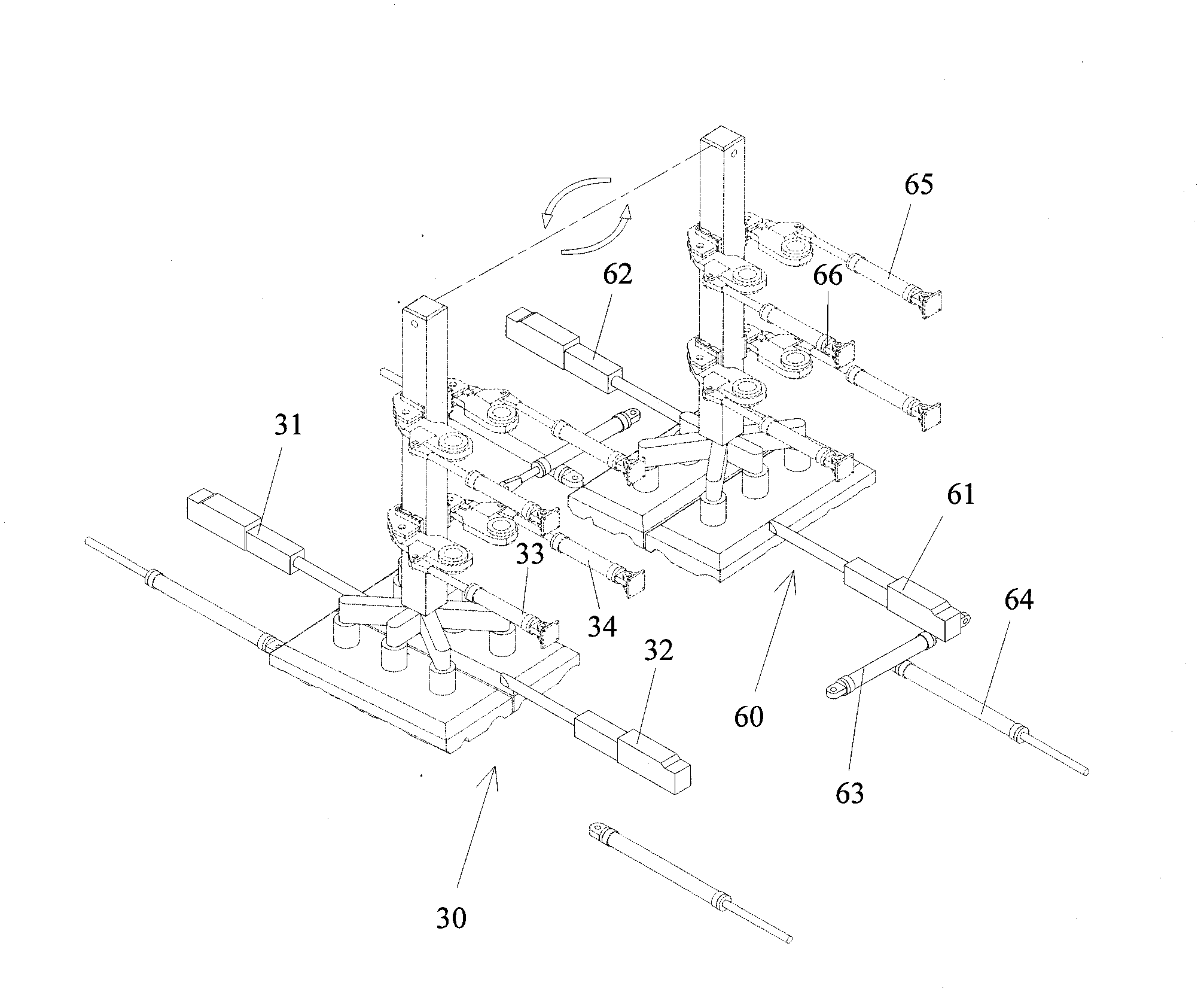

[0021] figure 1 Shown is the production line system for removing alumina crust blocks of the present invention; the production line system is arranged in a "one" shape, and is divided into an upper station station (accommodating five residual pole groups), two mechanical vibration and loosening stations ( Respectively accommodate one pole residue group), manual cleaning station (accommodate four pole residue groups) and down station station (accommodate five pole residue groups). The following are the basic parameters of the double anode group cleaned up by the production line system of the present invention:

[0022] Normal anode size: ~1500x 1330(2x660+10)x 550mm

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com