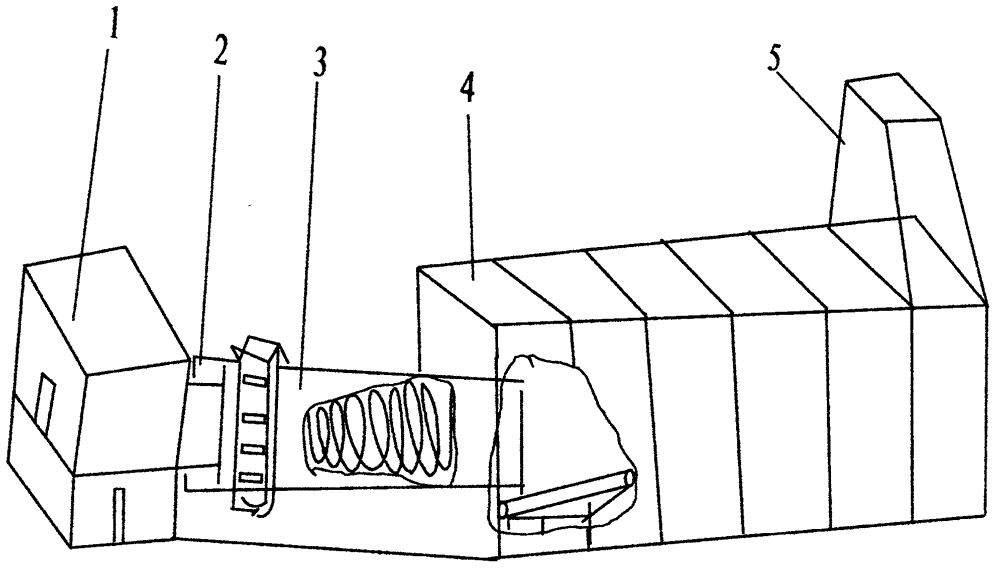

Method for manufacturing dedusting and radiating device of guilloche dryer of fertilizer drying oven

A technology of heat dissipation device and connecting ring, which is applied in the directions of dryer, drying, dryer combination, etc., can solve the problem of undiscovered drying process supporting facilities, etc., to achieve flexible control methods, meet application requirements, and ensure application effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

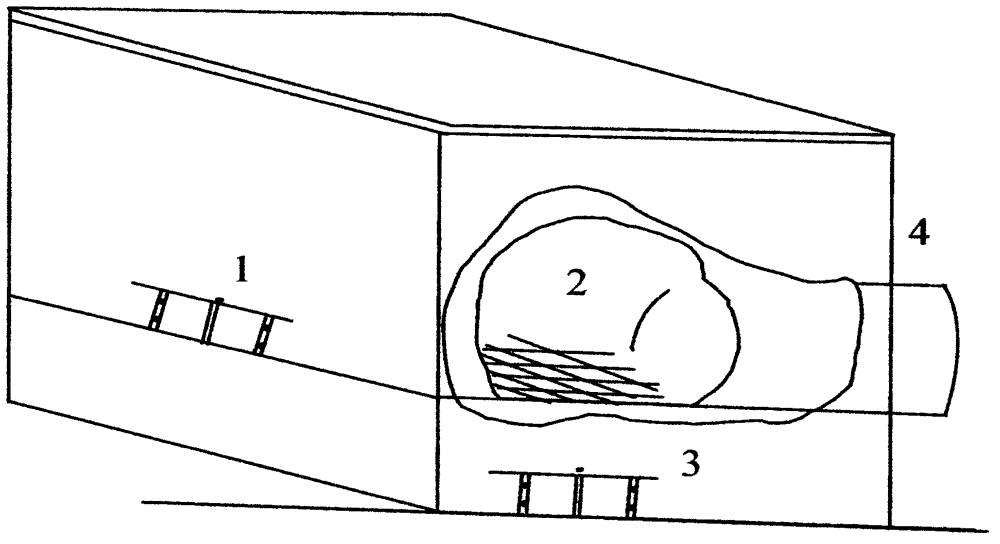

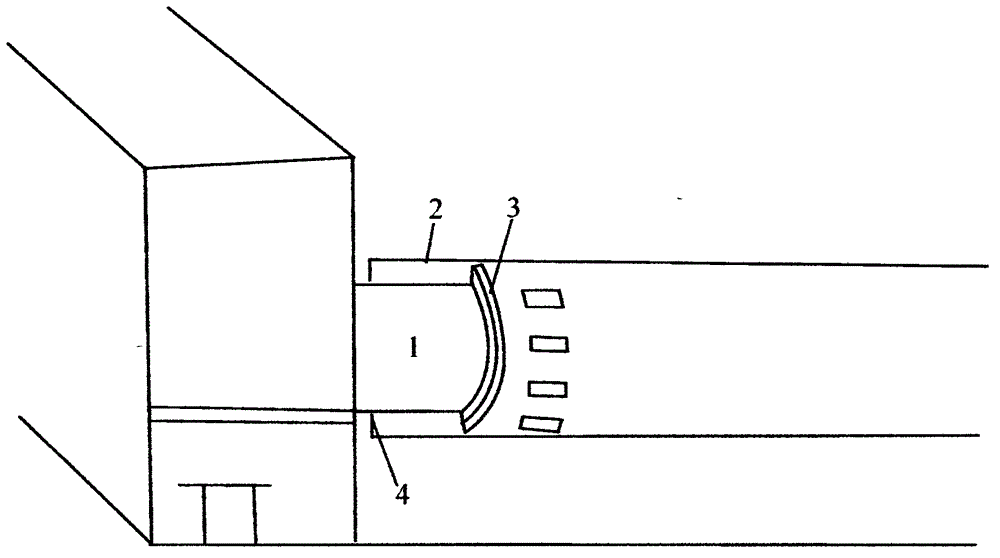

[0027] The first step is to build a refractory drying furnace first: after selecting the location, first determine the bottom area of the drying furnace: 3m×3m=9m 2and determine the center point, use the center point to determine the position of the air intake and oxygen slag discharge tank, and build a chassis with a height of 0.7m-0.9m; The radius draws the furnace bottom area of 1.539m 2 . Then draw the diameter with the center point, on the extension line of the diameter, leave a fuel inlet with a width of 0.4m and a height of 0.5m in the front, and connect a cylindrical hot air channel with a diameter of 1.2m in the back, and leave a 20cm-40cm long position at the rear end of the channel Ready to nest with dryer tumbler. When building the inner hearth, refractory bricks are used to build an arc-shaped furnace hall. The arch height of the inner hearth is required to be 1.3m-1.5m. The drying furnace is 3m high and has a total volume of 27m 3 , the inner layer is mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com