Method for calibrating ellipsometer with phase compensator

An ellipsometer and phase compensator technology, applied in the direction of measuring the polarization of light, instruments, scientific instruments, etc., can solve the problems of low precision, complexity, and the error between the actual angle and the angle that needs to be set, so as to improve the measurement accuracy, The effect of simplifying the measurement process and the simple calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

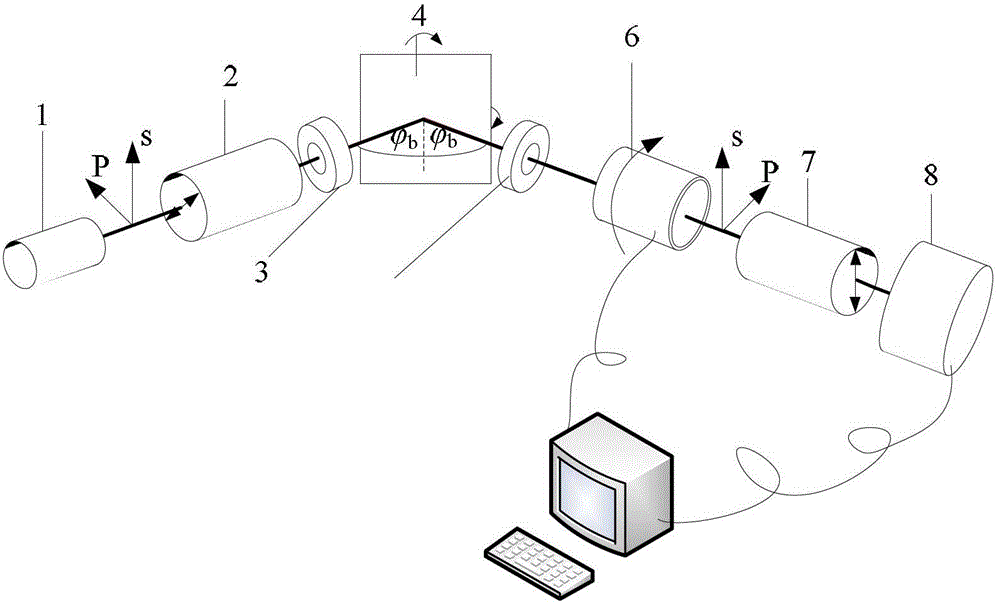

[0125] The angle calibration method of Embodiment 1 of the present invention is described below through specific steps, which can be divided into the following steps:

[0126] (1) Fix the polarizer and analyzer in the ellipsometer. Since the ellipsometer has high measurement accuracy at certain polarizer angles, before the measurement, the polarizer (including polarizer and analyzer) with known approximate transmission direction can be rotated to a suitable angle and fixed. For example, the angles between their transmission directions and the incident surface of the light beam on the sample are 45° and 22.5° respectively (actually due to the low accuracy of the transmission direction of the polarizer and operational errors, the transmission of the polarizer The vibration direction angle is hardly really on these two polarizer angles, but around here).

[0127] (2) Measure the first reference sample: Rotate the compensator at a constant speed, load the first reference sample w...

Embodiment 2

[0132] The angle calibration method of Embodiment 2 of the present invention is illustrated below through specific steps, which can be divided into the following steps:

[0133] (1) Fix the polarizer and phase compensator in the ellipsometer.

[0134] (2) Measure the first reference sample: Rotate the analyzer at a constant speed, load the first reference sample with known optical constants and thicknesses (n1, k1, d1), measure through the above ellipsometry, and obtain the light intensity curve I 1 (t).

[0135] (3) Measure the second reference sample: load the second reference sample with known optical constant and thickness (n2, k2, d2), repeat the measurement in step 2, and obtain the light intensity curve I 2 (t).

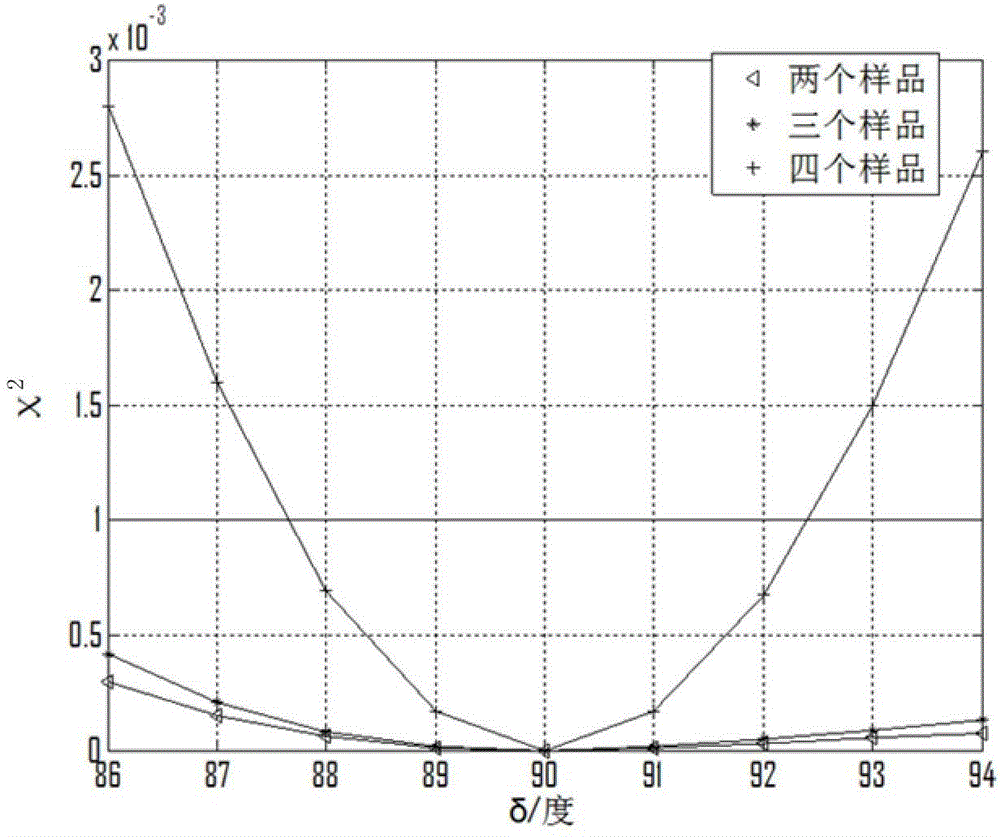

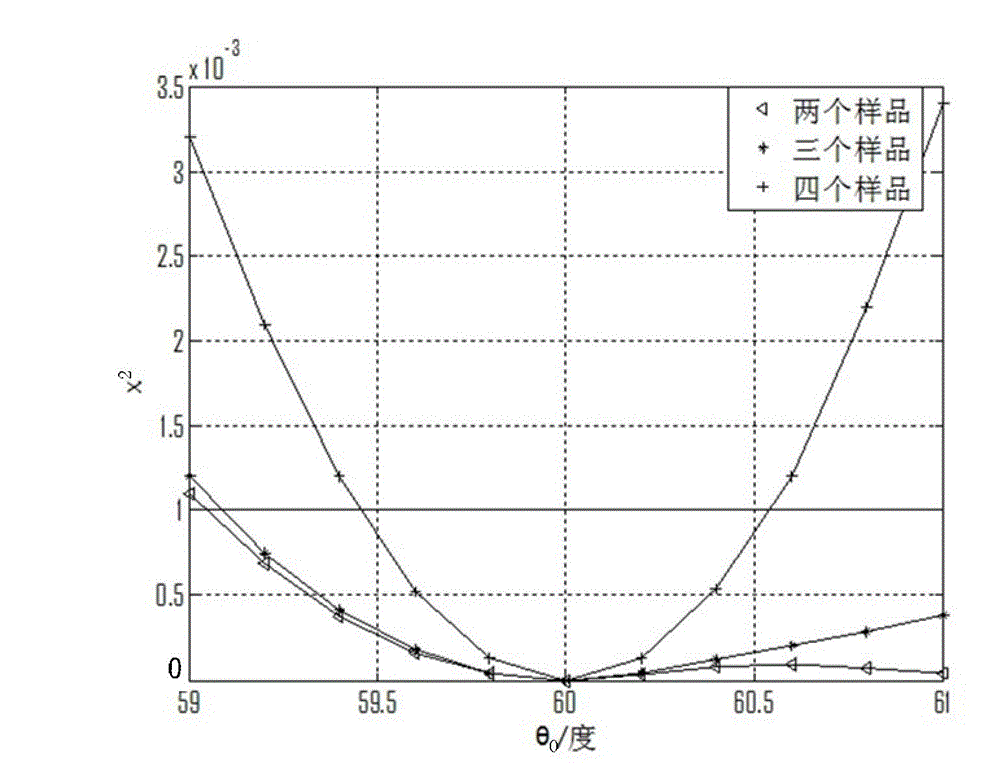

[0136] (4) Obtain experimental Fourier coefficients through Fourier expansion: According to the light intensity curve obtained from the above measurement, Fourier expansion or fitting can be performed to obtain two sets of Fourier coefficient values (α' 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com