Single-side high-temperature testing device of hypersonic aircraft material in 1800-degree aerobic environment

A hypersonic, high-temperature test technology, applied in the direction of material thermal development, can solve the problems of heat-proof materials and heat-proof structures, and achieve the effect of good temperature field uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

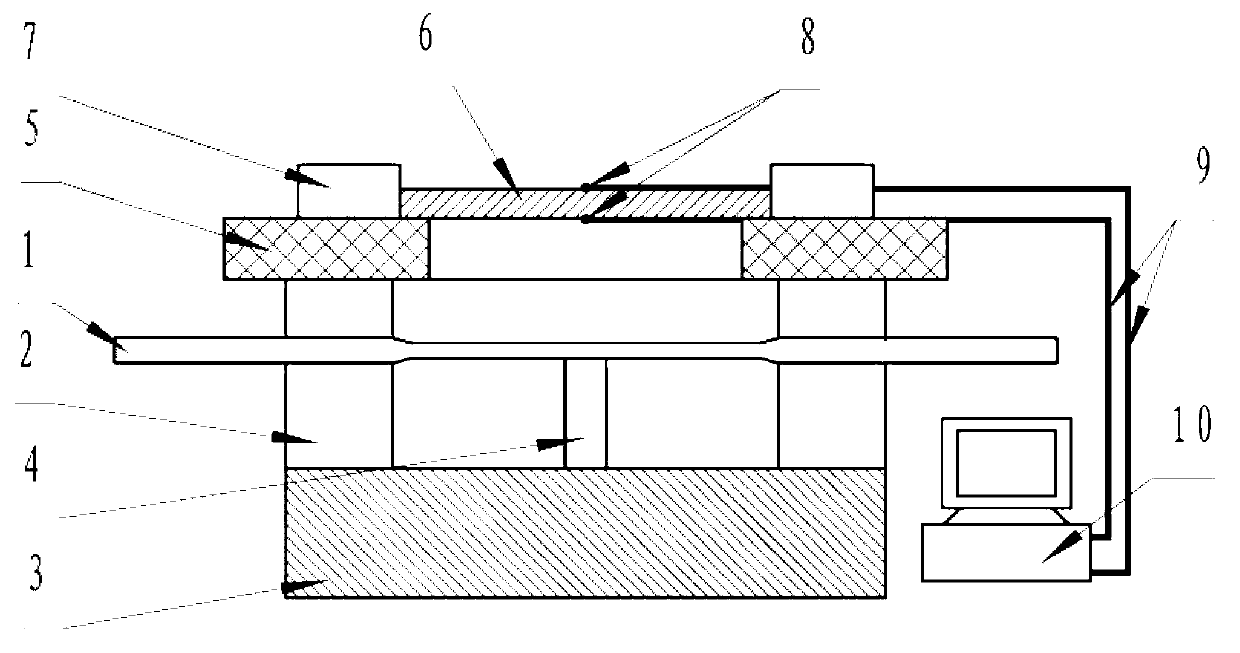

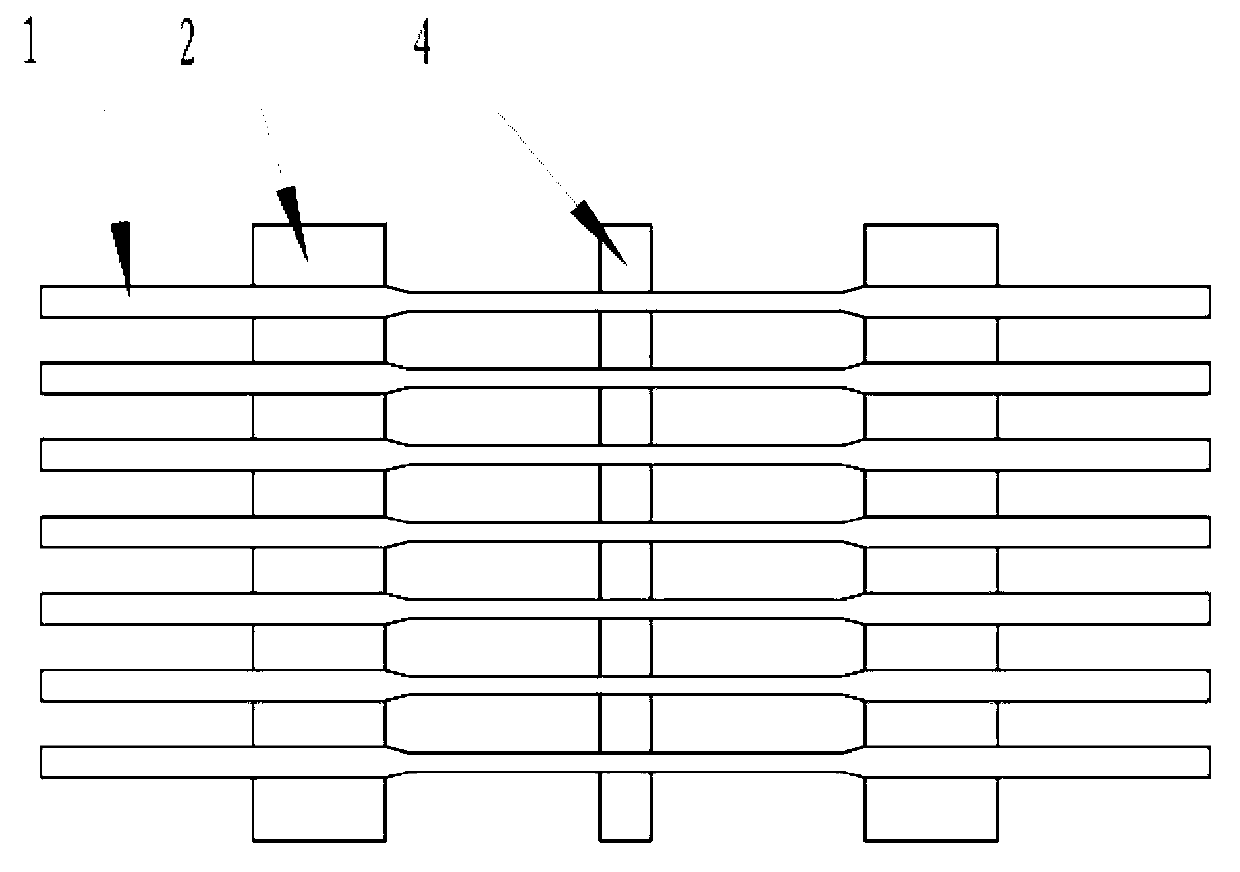

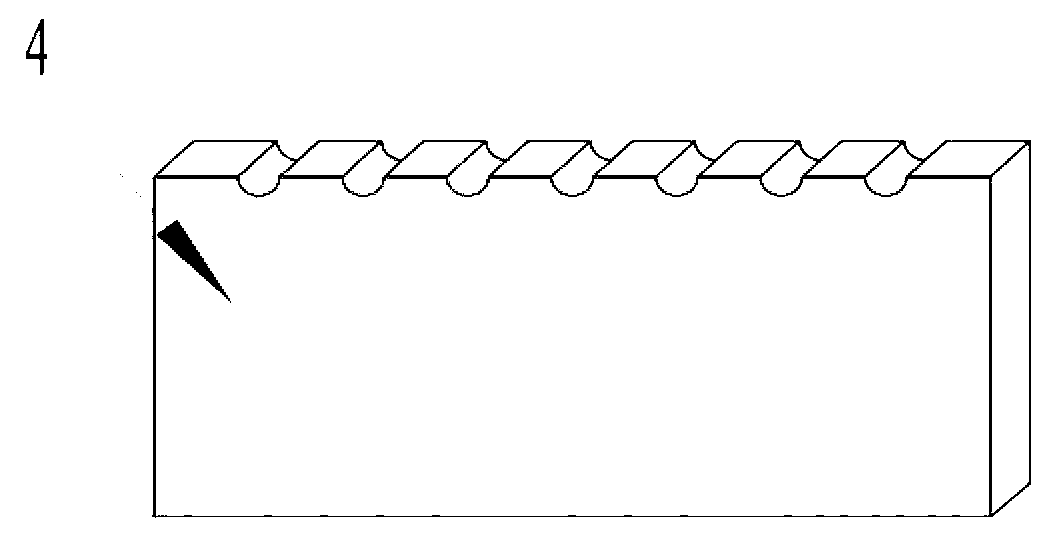

[0024] Such as figure 1 , figure 2 with image 3As shown, the present invention consists of a silicon-molybdenum heater array 1, a high-temperature ceramic support 2, a thermal insulation base 3, a middle support frame 4 of a silicon-molybdenum heater, a high-temperature ceramic plate 5, a hypersonic aircraft plane test piece material 6, a high-temperature insulation The thermal material 7, the thermocouple temperature sensor 8, the wire 9 and the computer 10 are composed. The silicon-molybdenum heater array 1 is fixed in the round hole of the high-temperature ceramic support 2 to form a horizontal and densely arranged planar heating array. The ceramic support 2 is fixed on the heat insulation base 3, the silicon-molybdenum heater support frame 4 is placed in the middle of the silicon-molybdenum heater array 1, and the high-temperature ceramic support 2 is equipped with a high-temperature ceramic plate 5 with square heat-through holes. , the hypersonic aircraft plane test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com