Simulation method for gas static pressure main shaft dynamic predication

A technology of gas static pressure and simulation method, applied in the field of dynamic simulation, can solve the problems of low precision, difficult modeling, difficult prediction of dynamic characteristics of the main shaft, etc., and achieve the effect of accurate prediction of dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

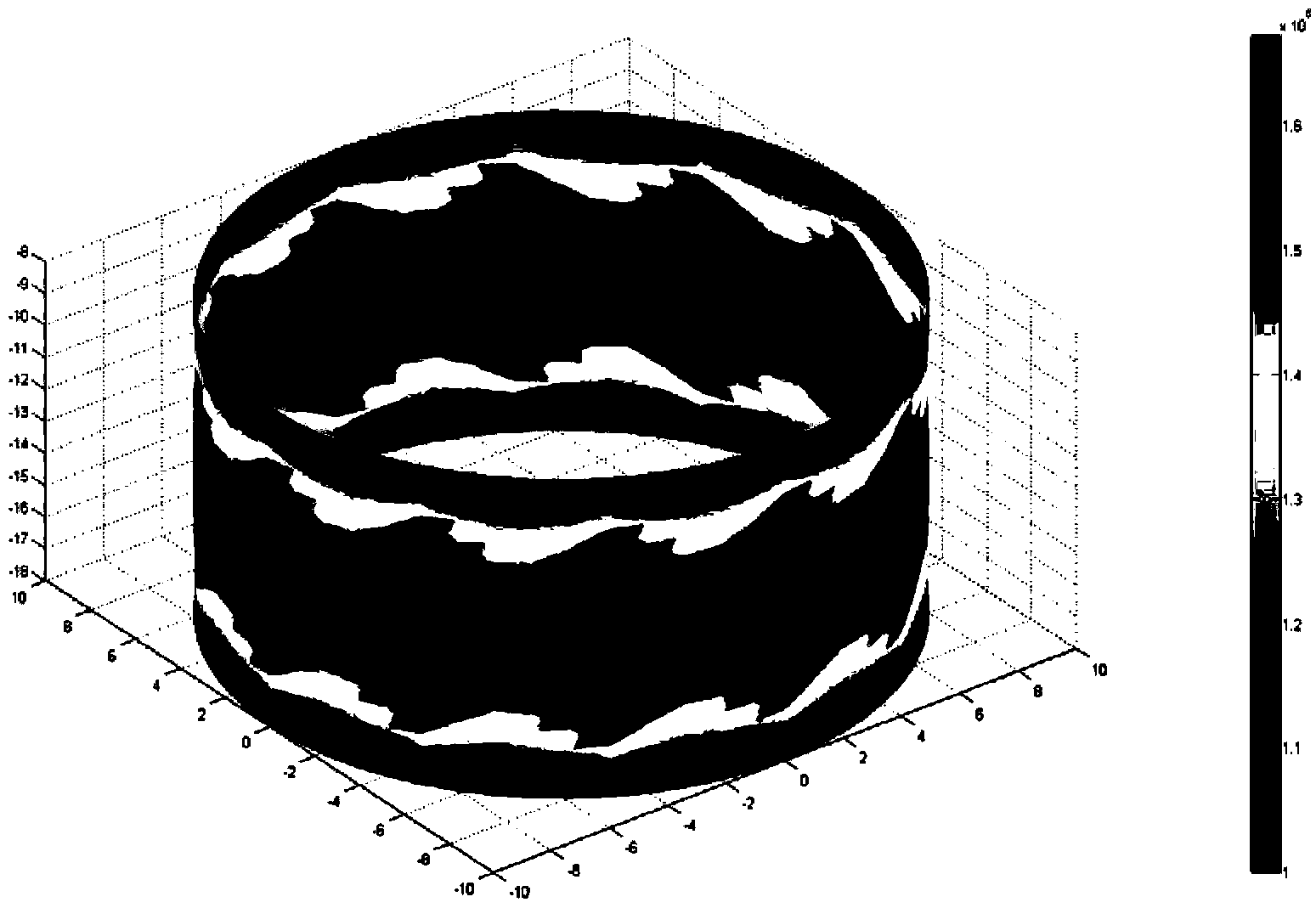

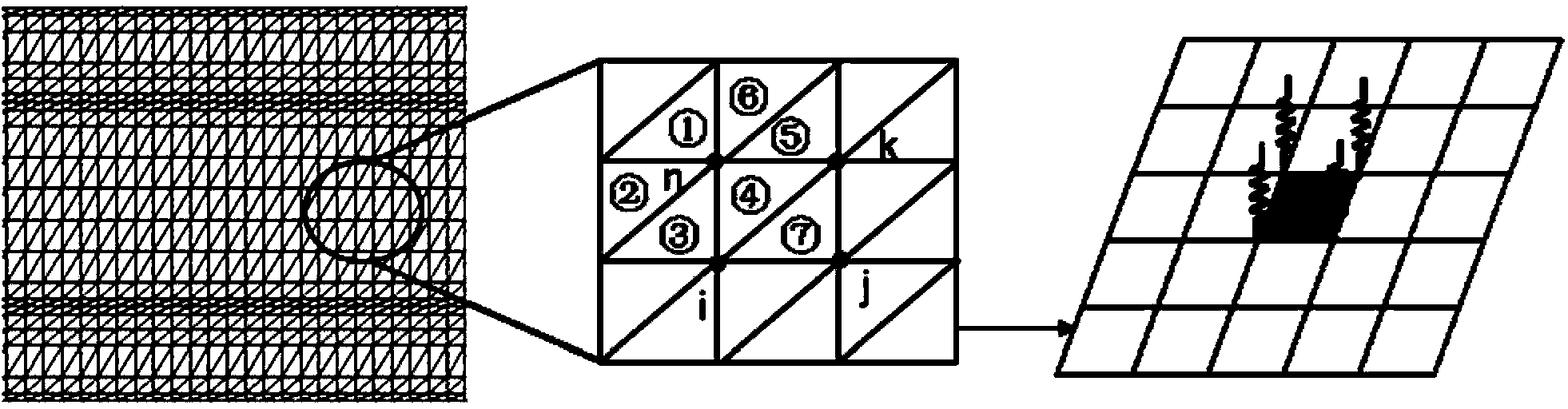

[0019] Specific implementation mode 1. Combination Figure 1-7 Describe this specific embodiment, this specific embodiment is the simulation method that is used for aerostatic spindle dynamics prediction, and its steps are as follows:

[0020] Step 1: Using the finite element method and the principle of gas static pressure, the gas static pressure spindle bearing gas film is divided into finite element grids, and the pressure distribution data We of the gas static pressure spindle is calculated; the gas static pressure spindle includes the gas static pressure Spindle bearing air film and gas static pressure spindle shaft body;

[0021] Step 2: Establish a corresponding finite element model of the main shaft body according to the finite element grid obtained in step 1, and the finite element model represents the solid unit of the aerostatic main shaft body;

[0022] Step 3: Convert the pressure distribution data We of the finite element principal axis obtained in step 1 into a...

specific Embodiment approach 2

[0026] Embodiment 2. This embodiment is different from Embodiment 1 in that step 1 of the simulation method for the dynamics prediction of the gas static pressure spindle utilizes the finite element method and the principle of gas static pressure, through the analysis of the gas static pressure spindle The bearing gas film is divided into finite element grids, and the method of calculating the pressure distribution data We of the gas static pressure spindle is as follows:

[0027] Applying the Reynolds equation to calculate the pressure distribution of the air film of the aerostatic spindle bearing, the Reynolds equation is Formula 1:

[0028] ∂ ∂ x ( h 3 p ∂ p ∂ x ) + ∂ ...

specific Embodiment approach 3

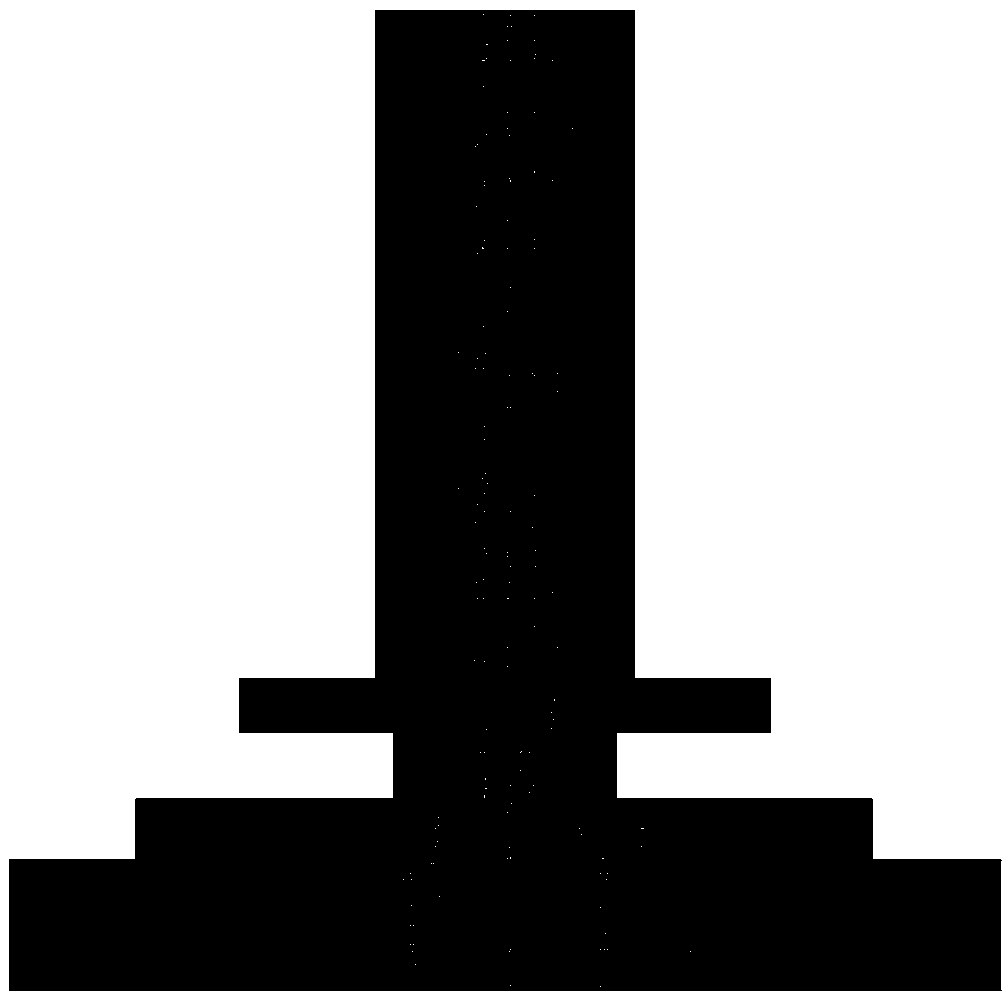

[0047] Specific Embodiment 3. The difference between this specific embodiment and specific embodiment 1 is that in the step 3 of the simulation method for dynamics prediction of the gas static pressure spindle, the pressure distribution data We of the finite element spindle obtained in step 1 are transformed into is the equivalent spring stiffness value, and assigns the equivalent spring stiffness value to the node corresponding to the gas film finite element grid, the process of obtaining the equivalent spring element is:

[0048] Step 3A converts the pressure distribution data We of the finite element spindle obtained in step 1 into a stiffness value through formula 5;

[0049] K e = ∂ W ‾ e ∂ h formula five

[0050] Where Ke is the stiffness value of the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com