Method for improving etched via bottom critical dimension of 40 nm dual damascene structure

A technology of etching gas and grooves, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as unfavorable formation, bending, affecting electrical properties and yield, and achieve the effect of increasing critical dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

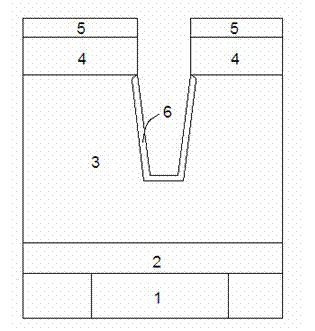

[0023] According to the unique characteristics of the ultra-low-k dielectric insulating layer, the present invention proposes a method that can not only protect the sidewall of the low-k dielectric insulating layer, but also increase the critical dimension of the bottom of the through hole.

[0024] The following examples illustrate the improvement methods provided by the present invention in further detail in order to better understand the content created by the present invention, but the content of the examples does not limit the scope of protection created by the present invention.

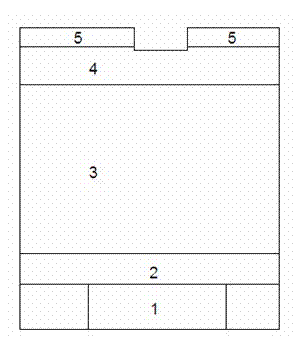

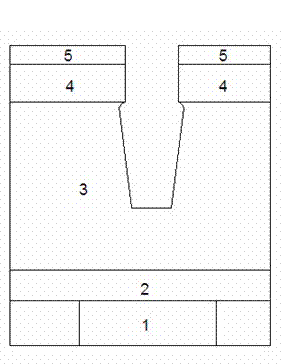

[0025] The overall improvement of the key dimensions of the 40nm double damascene structure to etch the bottom of the through hole includes three parts: a trench etching step, a step of forming a sidewall protection layer of an ultra-low-k dielectric insulating layer, and a step of forming a through hole that exposes the metal layer.

[0026] Such as figure 1 with 2 As shown, the trench etching step is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com