Photoelectric mixed connector

An optoelectronic hybrid and connector technology, which is applied in the direction of connection, components and circuits of connecting devices, can solve the problems of complex structure, inability to arrange the high-voltage insertion interface, and difficulty in controlling the force at the high-voltage insertion interface. Compact and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

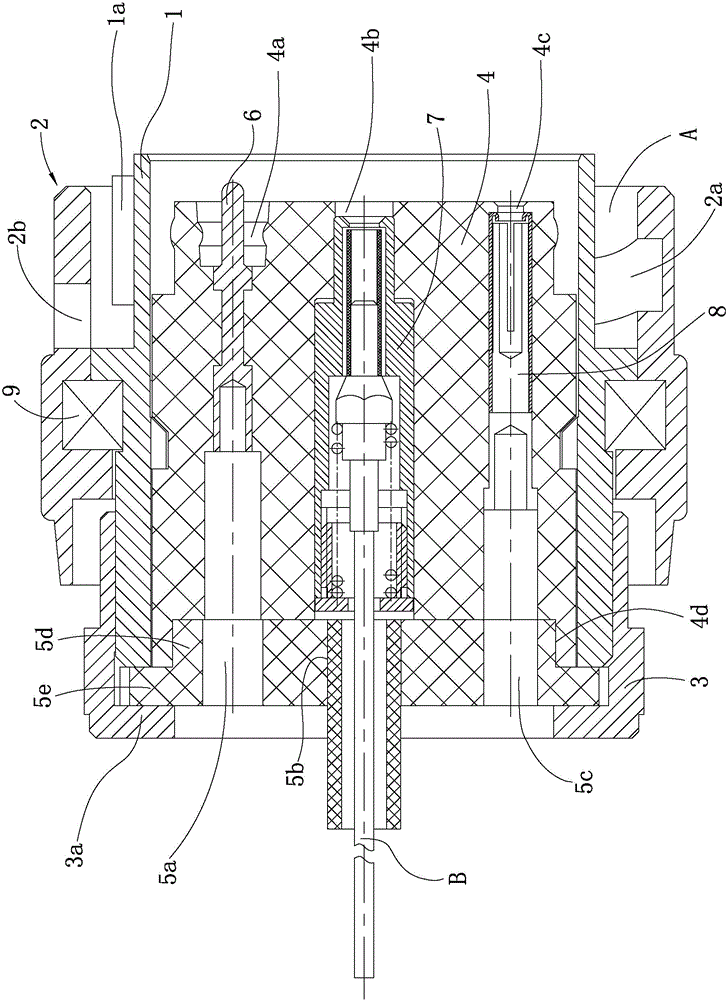

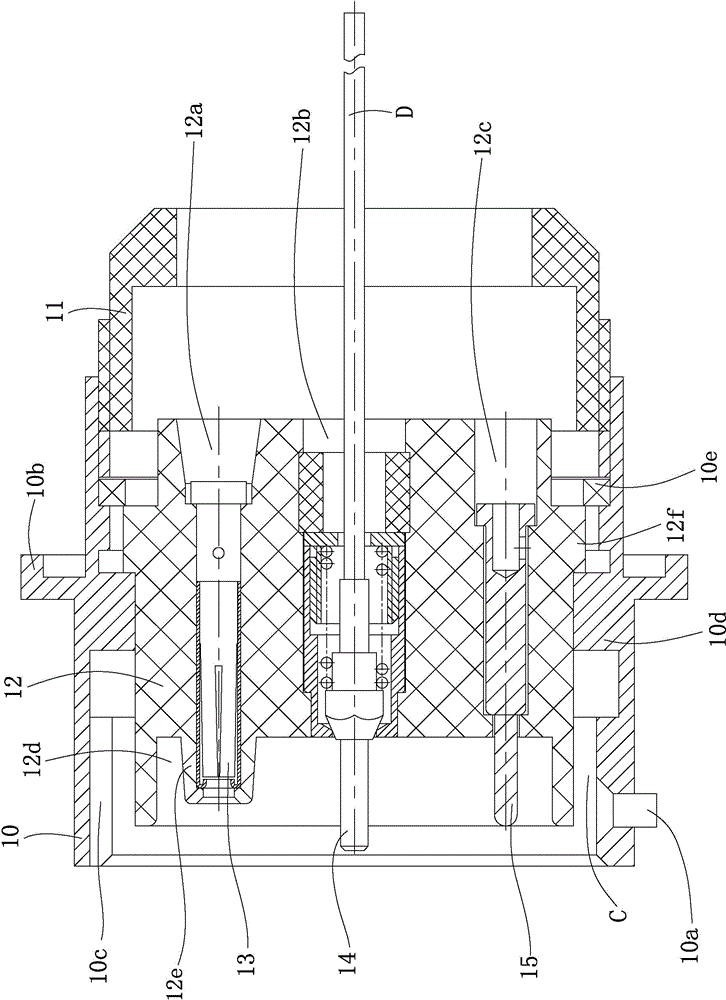

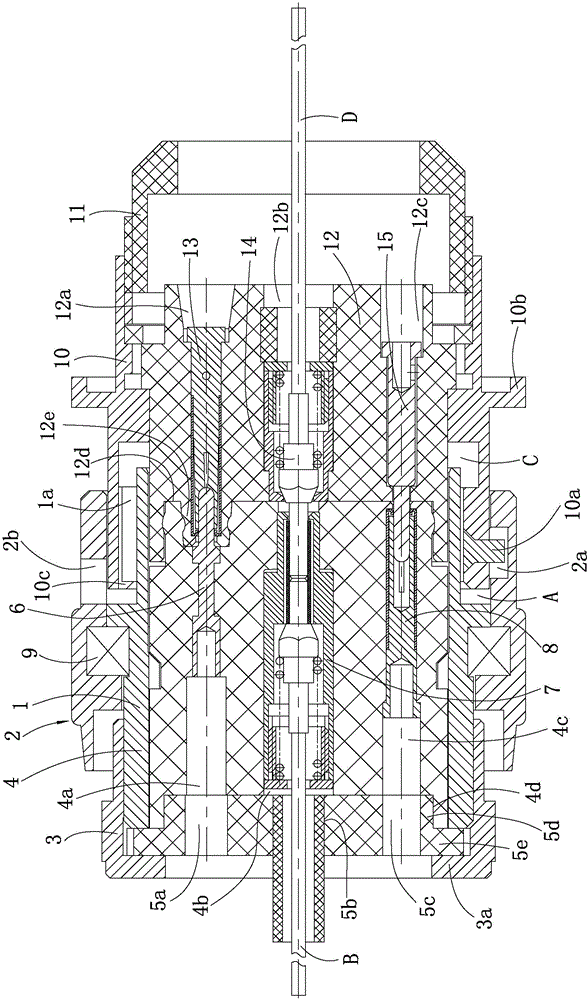

[0044] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings:

[0045] see figure 1 - Figure 5 :

[0046] This connector consists of a plug and a socket.

[0047] The structure of the plug itself and the connection between parts are as follows:

[0048] The plug includes a plug housing 1, a connecting sleeve 2, a nut 3, a circular plug mounting plate 4, a baffle plate, four high-voltage pin assemblies 6 respectively used to connect the high-voltage wires of the plug, and an optical fiber used to connect the optical fiber wire B of the plug. Jack assembly 7, seven low-voltage jack assemblies 8 respectively used to connect plug low-voltage wires. The cross section of the inner cavity of the plug housing 1 is circular, and the cross section of the connecting sleeve 2 is circular. For the sake of succinctly explaining the problem, the high-voltage wires of the plug and the low-voltage wires of the plug are not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com